Heat Transfer Roller

Siva Rollers is a leading Heat Transfer Roller Manufacturer in India, delivering precision‑engineered rollers for high‑temperature industrial applications. Our heat transfer rollers are designed for continuous operation in textile processing, lamination, printing, packaging, and coating lines where uniform heat transfer, dimensional accuracy, and long service life are critical.

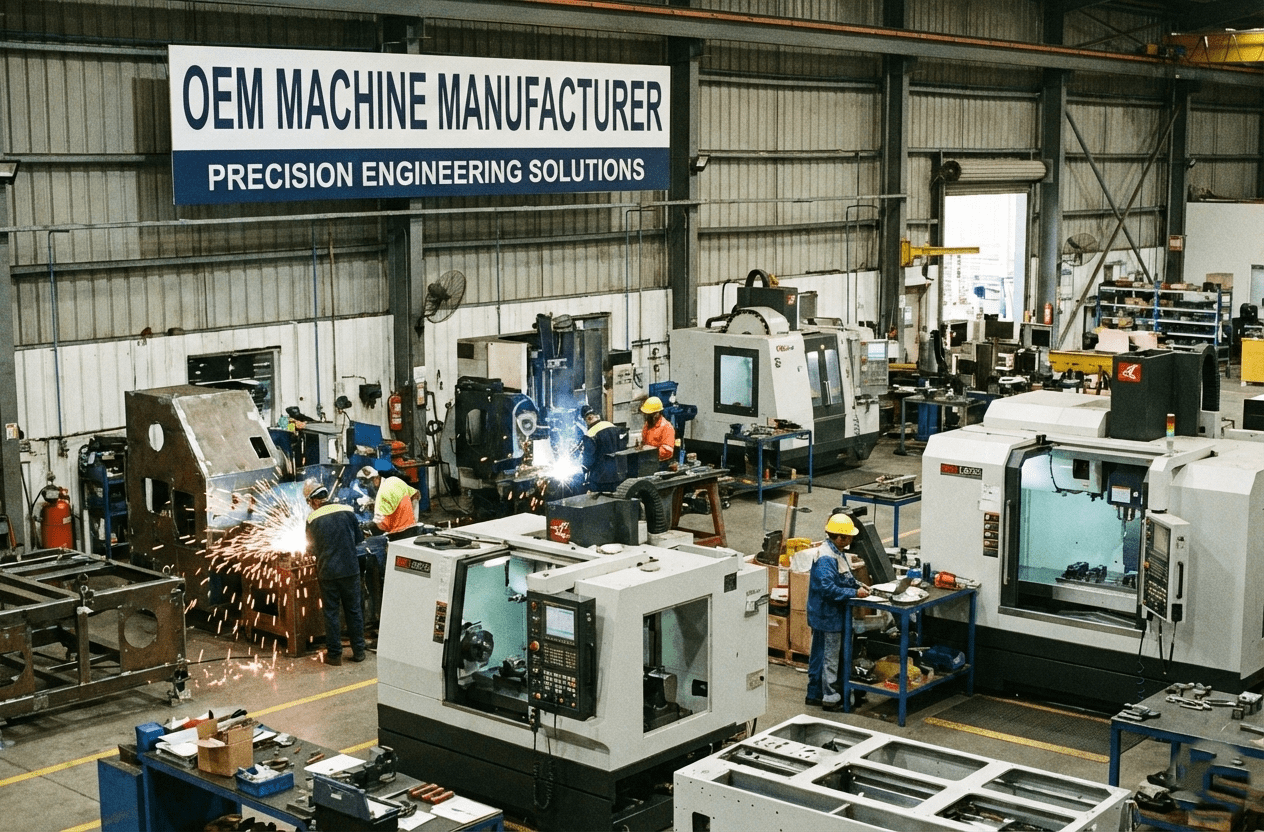

With decades of manufacturing expertise, advanced rubber compounding, and strict quality control systems, Siva Rollers supplies industrial heat transfer rollers to OEMs and production plants across India and global export markets.

If you need high‑temperature resistant rollers that perform consistently, reduce downtime, and improve product quality, Siva Rollers offers a proven and cost‑effective solution.

Industrial Heat Transfer Rollers Built for Demanding Production Lines

A heat transfer roller is a critical rotating component used to transfer controlled heat onto substrates such as fabrics, films, foils, papers, and coated materials. These rollers are used in processes such as:

- Textile sublimation and calendaring

- Thermal lamination

- Hot melt coating

- Heat sealing and bonding

- Printing and finishing lines

Any inconsistency in surface temperature, hardness, or concentricity directly affects output quality, registration accuracy, and production efficiency.

Siva Rollers manufactures precision engineered heat rollers that deliver:

- Uniform surface temperature distribution

- Stable dimensional accuracy at elevated temperatures

- High resistance to cracking, glazing, and deformation

- Long operational life with minimal maintenance

Why Siva Rollers is a Trusted Heat Transfer Roller Manufacturer

As an established industrial roller manufacturer, Siva Rollers focuses on performance reliability, technical accuracy, and application‑specific customization.

Our competitive advantages:

- In house rubber compounding for temperature specific formulations

- CNC grinding and dynamic balancing for perfect concentricity

- Controlled curing processes for thermal stability

- Strict inspection protocols for hardness, runout, and surface finish

- Proven export supply capability

We are not a trading company. Every heat transfer roller is manufactured under direct technical supervision at our facility in India.

High Temperature Resistant Roller Compounds

Heat resistance is the most critical factor in thermal transfer applications. Siva Rollers formulates rubber compounds engineered to withstand continuous high temperatures without surface breakdown.

Performance Benefits

- No glazing or surface hardening

- Minimal thermal expansion

- Stable hardness at operating temperatures

- Resistance to cracking and brittleness

- Long service intervals

Precision Engineered Heat Rollers for Uniform Heat Transfer

Uniform heat transfer depends on surface accuracy, material consistency, and internal bonding quality.

Our production process ensures:

- Perfect rubber to metal bonding

- Controlled rubber thickness

- Uniform hardness across the roller face

- CNC grinding for surface accuracy

- Thermal cycling tests before dispatch

This results in thermal transfer rollers that maintain consistent surface contact and heat flow across the full roller width.

Customized Heat Transfer Rollers for OEM and Replacement Use

Every production line has different load conditions, temperatures, and substrate characteristics. Siva Rollers supplies customized heat transfer rollers for:

- New OEM machine builds

- Replacement rollers for imported machines

- Upgraded performance specifications

- Special surface profiles and textures

Customization Options

- Diameter and face length

- Shaft design and bearing journals

- Rubber compound selection

- Hardness levels

- Surface texture or coating

- Keyways, grooves, and flanges

Heat Transfer Rollers for Textile Industry

The textile sector demands the highest accuracy and surface stability.

Our heat transfer rollers for textile industry are used in:

- Sublimation printing

- Calendaring machines

- Heat setting units

- Fabric lamination lines

Textile‑Specific Advantages

- Uniform fabric contact

- No surface marks or streaks

- High abrasion resistance

- Stable performance at elevated temperatures

- Low maintenance requirements

Applications Across Multiple Industries

Siva Rollers supplies industrial heat transfer rollers for a wide range of sectors.

Key Application Areas

Export Quality Heat Transfer Rollers

Siva Rollers is a recognized heat transfer roller supplier in India with export capability.

Export Readiness

- International packing standards

- Dimensional documentation

- Quality certificates

- Custom labeling

- Global logistics support

We currently supply rollers to buyers in Asia, Middle East, Africa, and European markets.

Quality Control and Manufacturing Standards

Every roller is manufactured under a documented quality control system.

Inspection Parameters

- Rubber hardness verification

- Surface finish measurement

- Concentricity and runout testing

- Bond strength testing

- Visual and dimensional checks

This ensures consistent performance across every shipment.

Get a Quotation from a Trusted Heat Transfer Roller Manufacturer

If you are searching for a reliable heat transfer roller manufacturer in India, Siva Rollers offers performance‑driven solutions tailored to your process requirements.

Request Your Custom Quote Today

- Roller drawing or dimensions

- Operating temperature

- Application details

- Quantity requirement

- Delivery location

Our technical team will respond with a competitive quotation and lead time.

FAQs

A heat transfer roller is an industrial roller used to apply controlled heat to materials such as fabric, film, paper, or foil during processes like textile sublimation, lamination, coating, printing, and heat sealing.

Heat transfer rollers are widely used in the textile industry, packaging and lamination plants, printing units, film and foil converters, paper processing factories, and OEM machine manufacturing.

Roller quality directly affects product finish, bonding strength, printing accuracy, and rejection rates. Poor-quality rollers can cause uneven heating, surface marks, downtime, and frequent replacements.

Choose a manufacturer with in-house production, application-specific customization, proven industry experience, and strong quality control systems. A reliable supplier should provide technical guidance, not just sell a standard roller.

Yes. Siva Rollers manufactures customized heat transfer rollers based on your machine type, application, substrate, and operating conditions to ensure perfect fit and consistent performance.

Yes. Industrial-grade heat transfer rollers are designed for continuous operation in high-temperature and high-load production environments.

Lead time depends on the level of customization, order quantity, and production schedule. Standard and repeat orders are usually delivered faster than first-time custom designs.

Yes. Export-quality heat transfer rollers from manufacturers like Siva Rollers match or exceed the performance of imported rollers at a lower cost and with faster delivery and local technical support.

Yes. Siva Rollers supplies heat transfer rollers across India and also exports to international markets including Asia, the Middle East, Africa, and Europe.

Pricing depends on application requirements, customization level, rubber compound selection, roller size, order quantity, and delivery location.

Yes. Siva Rollers manufactures heat transfer rollers for new OEM machine builds as well as replacement rollers for Indian and imported machines.

You can contact Siva Rollers with your application details, machine information, and delivery location. Our technical team will review your requirement and provide a customized quotation promptly.