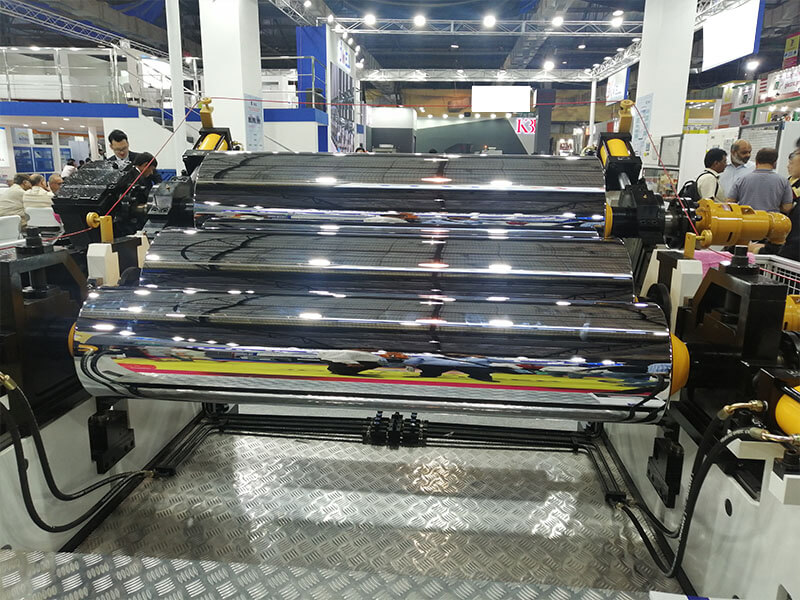

Calendering Roller

What Makes Calendering Roller So Essential?

But why are they so important?

In essence, calendering roller are a critical link between raw material and finished product.

What Sets Siva Roller Apart?

Custom Calendering Rollers We Offer

Dual-Zone Temperature Control Rollers

Ideal for plastic films and rubber sheets where temperature sensitivity is crucial. Internal fluid channels help maintain consistent temperatures across the roller width.

Precision Ground Surface Rollers

For industries like photographic paper and coated fabrics, where micron-level surface finish is a must. These rollers undergo fine grinding and polishing to reduce surface deviation.

Multi-Embossing Pattern Rollers

Perfect for high-volume packaging and decorative laminates, where different textures are needed on the same production line.

Tension-Control Calendering Roller

Built for the textile and non-woven fabric industry, these rollers maintain consistent tension during high-speed operations, reducing wrinkles and stretching.

Custom Calendering Rollers We Offer

Dual-Zone Temperature Control Rollers

Ideal for plastic films and rubber sheets where temperature sensitivity is crucial. Internal fluid channels help maintain consistent temperatures across the roller width.

Precision Ground Surface Rollers

For industries like photographic paper and coated fabrics, where micron-level surface finish is a must. These rollers undergo fine grinding and polishing to reduce surface deviation.

Multi-Embossing Pattern Rollers

Perfect for high-volume packaging and decorative laminates, where different textures are needed on the same production line.

Tension-Control Calendering Roller

Built for the textile and non-woven fabric industry, these rollers maintain consistent tension during high-speed operations, reducing wrinkles and stretching.

Sector-Specific Applications of Calendering Rollers

Our calendering roller are customized not just by size and material, but also by application. Here’s how Siva Roller contributes to various industries:

Automotive Industry

Used in the production of rubberized fabrics, interior vinyl, and tire components, our rollers ensure perfect bonding and thickness uniformity for critical safety components.

Flexible Packaging

In packaging film manufacturing (PVC, PET, BOPP), calendering rollers are used for flattening and controlling gloss levels, directly impacting product shelf appeal.

Construction Materials

Used in producing vinyl flooring, roofing membranes, and composite boards, where consistent material strength and finish are crucial.

Medical Textiles & Films

We provide FDA-grade calendering roller for sterile packaging films and disposable medical fabric production, with tight controls on contamination and finish.

How Siva Roller Delivers Precision: Our Workflow

Our engineering process combines precision craftsmanship with innovation. Here’s a peek into our workflow:

CAD-Based Roller Design

Every roller starts with digital modeling for accuracy. Designs are optimized for load-bearing, thermal behavior, and longevity.

Advanced Machining

We use high-precision CNC and VTL machines to achieve optimal concentricity and surface uniformity.

Surface Treatment

Rollers are coated with hard chrome, ceramic spray, or polyurethane depending on the application, to enhance wear resistance and surface quality.

Dynamic Balancing

Each roller is dynamically balanced to avoid vibration and ensure smooth high-speed operation.

Unique Features of Siva Roller Calendering Solutions

Our engineering process combines precision craftsmanship with innovation. Here’s a peek into our workflow:

CAD-Based Roller Design

Every roller starts with digital modeling for accuracy. Designs are optimized for load-bearing, thermal behavior, and longevity.

Advanced Machining

We use high-precision CNC and VTL machines to achieve optimal concentricity and surface uniformity.

Surface Treatment

Rollers are coated with hard chrome, ceramic spray, or polyurethane depending on the application, to enhance wear resistance and surface quality.

Dynamic Balancing

Each roller is dynamically balanced to avoid vibration and ensure smooth high-speed operation.

Unique Features of Siva Roller Calendering Solutions

Here’s what makes our calendering roller an industry favorite:

Corrosion and Wear-Resistant Surfaces

Our coatings and finishes stand up to harsh chemicals, heat, and abrasion, especially in rubber and plastic applications.

Uniform Heat Distribution

In heated calendering rollers, we ensure even thermal conductivity to avoid material warping or uneven bonding.

Low Run-Out and High Balance

With run-out values as low as 5 microns, we ensure smooth, consistent pressure across the entire working surface.

Enhanced Load-Bearing Capability

Heavy-duty bearing housings and alloy cores allow our rollers to handle intense pressure and continuous loads.

Sustainability and Longevity

Siva Roller supports environmentally conscious manufacturing by designing rollers that:

By extending the roller’s usable life, we help our customers cut down on both costs and carbon footprint.

Best Practices for Extending Roller Life

To get the most out of your Siva Roller calendering roller, follow these tips:

Why Manufacturers Trust Siva Roller

Clients from India and abroad consistently choose Siva Roller because we deliver:

We’re more than just a roller supplier — we’re your manufacturing partner.