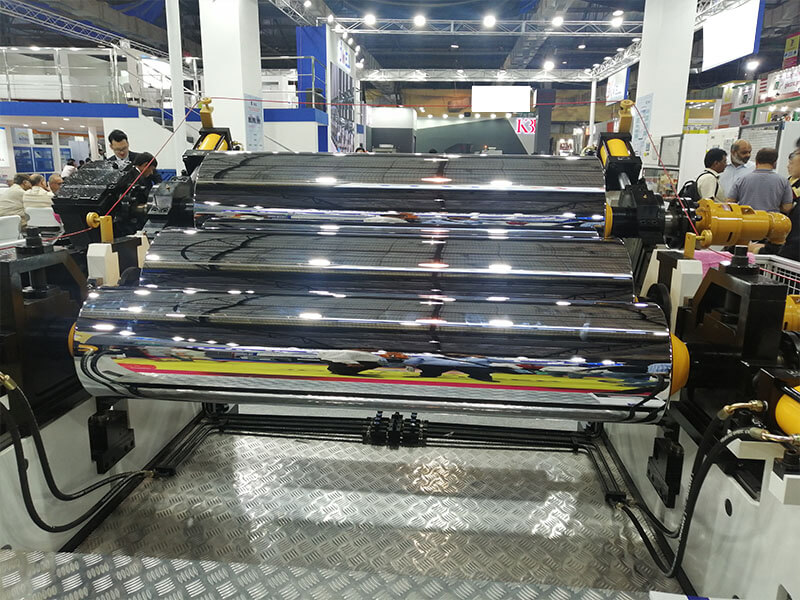

Calendering Roller

What Is a Calendering Roller?

In essence, calendering roller are a critical link between raw material and finished product.

Types of Calendering Roller

Hard Calender Rolls

Construction: Made from hardened steel or cast iron, often surface-coated with chrome or tungsten carbide for added wear resistance.

Applications: Commonly used in paper calendering and plastic sheet manufacturing, where high pressure is needed for smooth finishes and compact surfaces.

Advantages: Excellent surface finish, wear resistance, and long service life.

Soft Calender Rolls

Construction: Core metal shaft covered with a soft material like polyurethane, rubber, or cotton.

Applications: Ideal for textile calendering and lightweight paper finishing where a delicate touch is required to avoid damaging the material.

Advantages: Provides cushion effect, enhances gloss, and allows for uniform pressure distribution.

Heat Calender Rolls

Construction: Internally heated rollers using oil, steam, or electric systems; typically made from steel alloys with high thermal conductivity.

Applications: Used in plastic film manufacturing and thermal bonding applications, where temperature-sensitive processing is necessary.

Advantages: Ensures consistent heating, improves bonding, and reduces energy consumption.

Embossing Calender Rolls

Construction: One roller is engraved or etched with a pattern; the counterpart can be hard or soft depending on the embossing effect required.

Applications: Extensively used in textiles, leather finishing, decorative papers, and packaging to create embossed designs.

Advantages: Delivers high-definition patterns, enhances visual appeal, and improves product functionality.

Applications of Calendering Roller

Calendering rollers are essential across various industrial sectors, significantly impacting product quality, surface properties, and manufacturing efficiency.

Textile Industry

In textile calendering, rollers are used to smooth fabrics, impart a sheen, and apply finishes like embossing or glazing. Calendering enhances fabric strength and improves appearance, making it a key step in textile finishing.

Paper Industry

Paper calendering uses hard and soft rollers to adjust the paper’s thickness and surface smoothness. This process increases printability and imparts a glossy or matte finish depending on the roller combination.

Multi-Embossing Pattern Rollers

Perfect for high-volume packaging and decorative laminates, where different textures are needed on the same production line.

Tension-Control Calendering Roller

Built for the textile and non-woven fabric industry, these rollers maintain consistent tension during high-speed operations, reducing wrinkles and stretching.

Custom Calendering Rollers We Offer

Dual-Zone Temperature Control Rollers

Ideal for plastic films and rubber sheets where temperature sensitivity is crucial. Internal fluid channels help maintain consistent temperatures across the roller width.

Precision Ground Surface Rollers

For industries like photographic paper and coated fabrics, where micron-level surface finish is a must. These rollers undergo fine grinding and polishing to reduce surface deviation.

Rubber Industry

Rubber processing rollers help in forming, flattening, and texturizing rubber sheets. Calendering is crucial for achieving uniform thickness and improving mechanical properties, particularly in tire and seal manufacturing.

Plastics Industry

In plastic sheet manufacturing, calendering ensures accurate thickness, clarity, and finish. Heat calendering is especially important for films, vinyl flooring, and synthetic leathers.

Packaging Industry

Rollers in this sector are used for embossing and finishing packaging materials like foils, laminated sheets, and flexible packaging films. They ensure durability, aesthetics, and barrier properties.

Manufacturing Process at Siva Roller

At Siva Roller, every calendering roller is crafted with precision and a relentless focus on quality. Our advanced manufacturing process includes:

Material Selection

We begin with selecting the finest grades of steel, cast iron, or polymer composites based on the roller’s end-use. Material integrity ensures long-lasting performance and resistance to wear, heat, and pressure.

Precision Machining

Using CNC and advanced lathe machines, rollers are machined to micrometric tolerances. This ensures roundness, concentricity, and uniform pressure distribution during operation.

Heat Treatment

To enhance strength and wear resistance, rollers undergo specialized heat treatment processes such as hardening, tempering, and surface coating (chrome plating or tungsten carbide spraying).

Quality Inspection

Each roller is subjected to rigorous testing including hardness, concentricity, surface finish, and dynamic balance checks. Our in-house QA team ensures that only flawless products leave our facility.

This end-to-end quality control is what makes Siva Roller a trusted name in the global industrial rollers market.

Benefits of Siva Roller Calendering Roller

Our engineering process combines precision craftsmanship with innovation. Here’s a peek into our workflow:

CAD-Based Roller Design

Every roller starts with digital modeling for accuracy. Designs are optimized for load-bearing, thermal behavior, and longevity.

Advanced Machining

We use high-precision CNC and VTL machines to achieve optimal concentricity and surface uniformity.

Surface Treatment

Rollers are coated with hard chrome, ceramic spray, or polyurethane depending on the application, to enhance wear resistance and surface quality.

Dynamic Balancing

Each roller is dynamically balanced to avoid vibration and ensure smooth high-speed operation.

Unique Features of Siva Roller Calendering Solutions

Choosing Siva Roller means investing in performance, precision, and reliability. Our calendering roller offer a range of benefits:

High Precision and Uniformity

Engineered to exacting standards, our rollers deliver consistent results even in high-speed, high-pressure environments.

Durability and Long-Lasting Performance

Made with premium materials and hardened surfaces, our rollers withstand prolonged use with minimal degradation.

Versatility for Different Materials

From delicate textiles to rigid plastics, our calendering rollers can be customized for any material type or processing requirement.

Customizable Solutions

We understand that every industry has unique needs. That’s why we offer tailor-made designs, sizes, and surface finishes to match your specifications.

Cost-Effectiveness and Low Maintenance

Our rollers are designed for extended service life and require minimal upkeep, resulting in lower operational costs and higher ROI.

Maintenance Tips for Calendering Roller

Proper maintenance ensures that your calendering rollers deliver peak performance over time. Here are practical tips from Siva Roller:

Regular Cleaning

Remove dust, adhesives, or residue buildup using industry-approved cleaning agents. Avoid abrasive materials that can damage the roller surface.

Proper Lubrication

Lubricate bearings and moving parts regularly to reduce friction, wear, and operational noise.

Routine Inspections

Conduct visual and dimensional checks for signs of wear, misalignment, or surface damage. Early detection helps prevent costly downtime.

Safe Storage Practices

When not in use, store rollers in a clean, dry environment. Use roller cradles or hangers to prevent flat spots and surface deformation.

By following these practices, you can significantly increase the service life of your calender rollers and maintain product quality.

Why Choose Siva Roller?

With a legacy of excellence and a focus on innovation, Siva Roller has become the preferred partner for calendering solutions. Here’s why industry leaders trust us:

Industry Expertise

Years of experience in manufacturing industrial rollers for diverse applications.

High-Quality Materials

Sourced from trusted suppliers and rigorously tested for durability and performance.

Customized Design Solutions

Every roller is tailored to client specifications, ensuring perfect compatibility and efficiency.

Excellent Customer Support

Our team is always ready to assist with technical queries, customization requests, and post-sales support.

Whether you’re in textiles, paper, rubber, plastics, or packaging, Siva Roller is committed to helping you enhance productivity and product quality with the best calendering roller solutions.