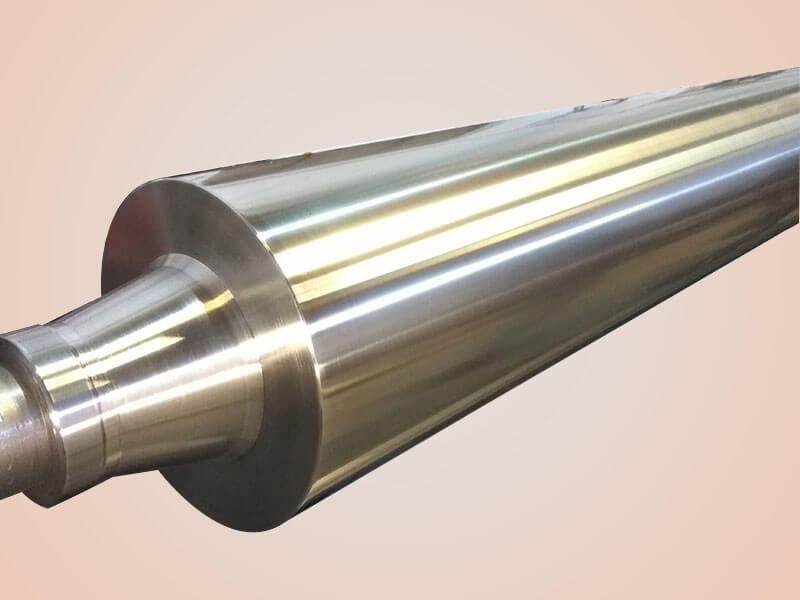

Stainless Steel Roller in Pune

If you’re searching for a Stainless Steel Roller in Pune that can handle pressure, resist corrosion, and meet the high standards of pharma, food, or flexible packaging industries, you’ve landed at the right place.

At Siva Rollers, we manufacture high-quality, precision-engineered Stainless Steel Roller Manufacturer and Stainless Steel Guide Roller Manufacturer in Pune, tailored for demanding industrial environments across Chakan, Bhosari, Ranjangaon, Talegaon, and other MIDC zones. Whether you’re running high-speed web processes or dealing with sensitive food or pharmaceutical materials, our rollers offer a worry-free, long-lasting solution.

What is a Stainless Steel Roller?

A Stainless Steel Roller is an industrial roller made using high-grade stainless steel (such as SS304 or SS316) designed to resist corrosion, wear, and chemical attack. These rollers are used to support, guide, or transport materials in industrial processes. They’re critical for ensuring smooth operations in systems like conveyors, printing machines, laminators, pouching machines, and more.

Example: In a flexible packaging line, a stainless steel guide roller ensures that thin plastic film moves straight and smooth, without wrinkles or misalignment.

You’ll find SS Roller commonly used in:

- Pharmaceutical machines

- Food-grade processing lines

- Printing and converting setups

- Label slitting and laminating lines

Why Stainless Steel Roller is the Right Choice for Pune Industries

Pune climate, especially in areas like Bhosari and Ranjangaon, includes high humidity levels and industrial environments prone to chemical exposure. That’s exactly where Stainless Steel Roller outperform mild steel or aluminum options.

Here’s why Pune industries prefer stainless steel:

- Rust-Free Performance: Stainless steel doesn’t corrode easily, making it ideal for food, pharma, or chemical plants.

- Food-Grade Hygiene: For sterile environments and FDA-compliant setups, SS roller are non-contaminating and easy to sanitize.

- Simple Maintenance: No need for frequent replacements or intensive upkeep—just clean, install, and forget.

- Long-Term Cost Savings: One-time investment, long-term durability.

Types of Stainless Steel Rollers Offered by Siva Rollers

We understand that not every application is the same. That’s why Siva Rollers offers a wide range of SS Roller variants in Pune, including:

By Material Grade:

- SS304 Rollers: Most commonly used; great for general industrial use.

- SS316 Rollers: Offers better resistance to chemicals and saltwater; suitable for pharmaceutical and food environments.

By Design/Functionality:

- Guide Rollers (for film and web direction)

- Conveyor Rollers (for material handling systems)

- Idle Rollers (non-driven support rollers)

- Live Shaft & Dead Shaft Rollers

By Build:

- Solid Core: Best for high-load applications.

- Hollow Core: Lighter, cost-efficient, ideal where weight is a factor.

By Surface Finish:

- Plain/Polished

- Mirror Finish

- Grooved or Crowned (for web control or grip)

Whatever your need, we have a customized SS Roller Pune solution ready.

Key Features of Siva Stainless Steel Roller

At Siva Rollers, we don’t just manufacture stainless steel rollers—we engineer solutions that run reliably, day after day. Our SS roller come with:

- Mirror-Polished Surface: Reduces drag, prevents material damage, and offers a clean, premium finish.

- Dynamic Balancing: Ensures vibration-free performance at high speeds.

- Precision Bearings & Shaft Fitment: Smooth rotation and minimal friction loss.

- Tension & Load Handling: Built to manage pressure, heat, and speed.

- Corrosion-Proof Design: Long life even in tough washdown zones.

Whether you’re handling flexible films or heavy web loads, our rollers will not let you down.

Stainless Steel Guide Rollers – Built for Web Precision

Stainless Steel Guide Roller in Pune are a must-have for machines that run flexible materials—like laminates, paper, films, foil, and labels.

These rollers are especially useful in:

- Laminating Machines

- Slitting & Rewinding Systems

- Pouching Lines

- Printing Presses

What makes our SS Guide Roller Pune special?

- Excellent Alignment: Guides film and web materials precisely across the machine bed.

- High Accuracy: No fluttering or vibration.

- Non-Stick Surface: Prevents ink, glue, or dust from sticking.

- Balanced Run: Ideal for high-speed operations with zero downtime.

If you’re in converting, packaging, or printing, you can’t afford misalignment—our guide rollers keep your web in line.

Common Problems Solved by Stainless Steel Roller

Stainless steel isn’t just about good looks. Our rollers solve real problems on the factory floor:

- Rusting Issues: In high-humidity areas like Pune or near cleaning stations, MS rollers start corroding. Stainless steel doesn’t.

- Product Contamination: In food or pharma, MS rollers can flake or rust, contaminating your product. SS rollers are 100% hygienic.

- Frequent Roller Failures: Our SS rollers reduce stoppages due to wear or shaft misalignment.

- Misaligned Webs: Our guide rollers bring web material back on track—literally.

Say goodbye to breakdowns and hello to worry-free production.

Advantages Over Mild Steel or Aluminum Rollers

When comparing Stainless Steel Roller to mild steel or aluminum options, the benefits are clear:

Feature | Mild Steel | Aluminum | Stainless Steel |

Rust Resistance | ❌ | ❌ | ✅ |

Suitable for Cleanrooms | ❌ | ❌ | ✅ |

Lifespan | Medium | Low | High |

Withstands Chemicals | Low | Medium | Excellent |

Ideal for Pharma/Food/Printing | ❌ | ❌ | ✅ |

So if you’re still using mild steel rollers and struggling with maintenance, breakdowns, or contamination, it’s time to switch to stainless steel.

Industries in Pune That Prefer Stainless Steel Rollers

Many advanced industries in Pune and surrounding MIDC zones trust Siva SS Rollers for their critical applications:

Why Choose Siva Rollers for Stainless Steel Rollers in Pune?

Whether you’re running high-speed packaging lines in MIDC Chakan, precision printing setups in Bhosari, or pharmaceutical processes in Hinjewadi or Pirangut, Siva Rollers is the trusted partner that delivers more than just rollers—we deliver industrial peace of mind.

Here’s why Pune’s leading companies choose Siva Rollers as their Stainless Steel Roller Manufacturer:

1. Customized Stainless Steel Roller Manufacturing

At Siva Rollers, customization is not a premium—it’s standard. We tailor each roller to suit your application, load capacity, shaft design, and surface requirements.

We manufacture:

- SS304 or SS316 grade based on chemical exposure needs

- Solid or hollow-core SS rollers based on weight and application

- Crowned, grooved, or mirror-polished finishes

- Custom shaft lengths, keyways, journals, and bearing housings

Our engineers work closely with your team to ensure seamless integration into your machines.

2. Uncompromised Quality & Durability

We believe in “fit-and-forget” rollers. Our SS rollers are made with:

- Premium-grade stainless steel (certified SS304 / SS316)

- Precision balancing to avoid vibration at high speeds

- Mirror-polished finishes to reduce friction and contamination

- Heavy-duty bearings and precision-machined shafts

They are built to handle:

- High-speed webs

- Continuous tension

- Washdowns and chemical cleaning

So you don’t have to worry about early wear, corrosion, or failure.

3. In-House Manufacturing with Full Control

Unlike traders or resellers, we own the entire process. Every stainless steel roller is designed, machined, polished, and tested in our own facility.

This ensures:

- Strict quality control at every stage

- Timely delivery, even for urgent or bulk orders

- Greater cost-efficiency due to minimized outsourcing

You get the benefit of factory-direct pricing with OEM-level performance.

4. Experienced Team – Engineering Meets Practical Know-How

Our team isn’t just skilled on paper—they have real-world manufacturing experience. We understand how rollers perform under tension, how coatings interact with films, and what causes misalignment or drag.

Whether you need advice on:

- Choosing between SS304 and SS316

- Optimizing roller surface finish

- Balancing for high-speed applications

- Fixing alignment in pouching or laminating lines

—we’re here with insights that go beyond just selling a part.

5. Proven Track Record Across Industries

Siva Rollers has been a trusted name among:

- Pharma companies needing sterile, rust-proof rollers

- Food and beverage processors looking for hygiene-compliant SS components

- Flexible packaging manufacturers using our rollers in laminators, slitters, and winders

- Label printers and converting lines requiring precision guide rollers

Chances are, if you’re in Pune’s industrial belt, your competitors already trust us.

6. Quick Turnaround & Local Service

We know that downtime is costly. That’s why we:

- Stock critical roller parts

- Offer quick lead times for most roller builds

- Provide local delivery and service across Pune MIDCs

And if something goes wrong, we’re just one call away—not hundreds of kilometers distant.

7. Transparent Dealings, Long-Term Partnerships

We don’t believe in pushing a sale. We believe in becoming your go-to partner for anything roller-related.

That means:

- Honest guidance, even if we recommend a simpler or cheaper option

- No hidden costs or technical jargon

- Continued service even after the delivery is done

Siva Rollers – Stainless Steel Strength. Precision Built. Pune Proud.