Rubber Roller in India

Rubber roller are critical components in countless types of industrial equipment. Whether guiding, pressing, laminating, or conveying materials, these rollers keep processes smooth and predictable. Their flexibility and resilience make them ideal for handling a range of materials without damaging surfaces or disrupting machine function.

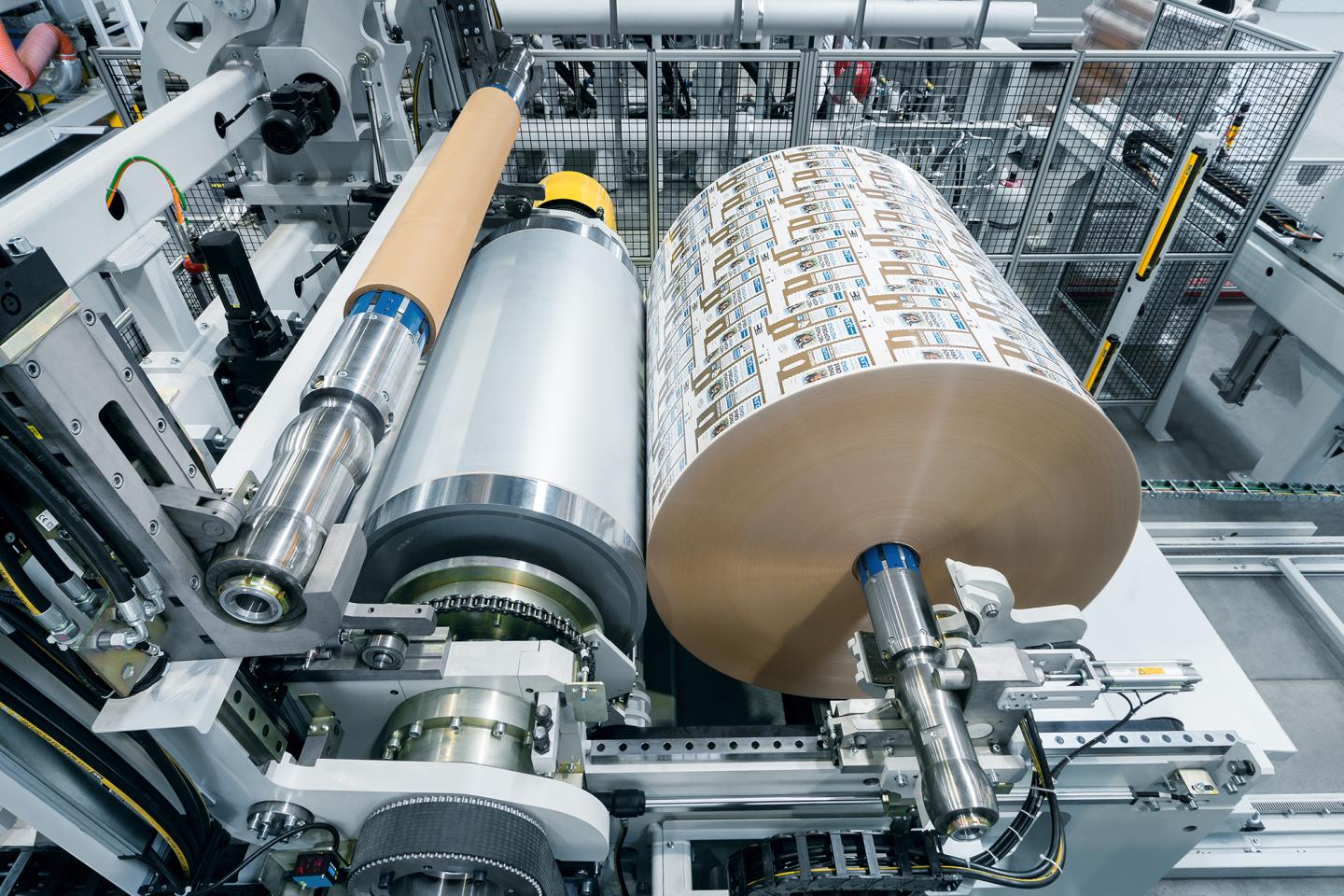

In high-output environments—like textile mills, printing presses, packaging lines, and metal processing plants—rubber rollers influence everything from product quality to equipment longevity. A well-made roller ensures stable rotation, reduces wear on other machine parts, and supports consistent output over long production runs.

Siva Rollers, based in Ahmedabad, has earned recognition as a reliable Rubber Roller in India by consistently delivering rollers that meet the expectations of engineers, maintenance heads, and production supervisors alike.

Key Qualities That Define a High-Performance Rubber Roller

A durable and efficient rubber roller must offer more than just basic function. The following attributes often separate high-performance rollers from short-lived ones:

- Vibration Absorption: Minimizes shock during operation, protecting the machine and improving print or press consistency.

- Precise Material Grip: Maintains control over substrates—whether fabric, paper, or film—without slipping or over-tensioning.

- Thermal Resistance: Performs reliably even under elevated machine temperatures or when exposed to heated materials.

- Long Operational Life: Handles high-speed operations and repetitive cycles without rapid surface degradation or deformation.

These features make the difference between a roller that quietly supports your operation and one that causes repeated downtime.

Industries That Rely on Rubber Roller

Different industries use rubber rollers for specific roles, but all depend on their consistent, non-damaging surface contact and ability to manage materials efficiently.

Each of these industries depends on specialized rollers—but the core expectations remain the same: stability, durability, and machine compatibility.

Why Indian Industries Prefer Siva Rollers

Many manufacturers operate in the Indian market, but not all understand the nuances of local industries. Siva Rollers brings something more than product supply to the table—a working knowledge of how Indian machinery is used and maintained.

Siva has built trust as a Rubber Roller Manufacturer that delivers on time, whether the need is for 10 pieces or 1,000. The company’s formulations use dependable rubber compounds selected to withstand real-world use in Indian climates and factory conditions.

By focusing on production-grade quality and maintaining stock for fast fulfillment, Siva has become a preferred partner for maintenance teams and machine OEMs alike. That’s why buyers looking for Rubber Rollers in India continue to return for repeat orders.

Common Problems with Low-Grade Rubber Rollers

Cutting costs on rubber rollers often leads to operational setbacks. Some of the most common issues that plant managers and maintenance teams report include:

- Inconsistent Rotation: Causes material tracking issues or output misalignment.

- Surface Peeling or Cracking: Often due to low-quality rubber that can’t handle repeated heating/cooling cycles.

- Machine Slippage: Results in start-stop movement, poor printing/lamination results, or material jamming.

- Premature Wear: Short roller life means more downtime and repeated replacement cycles—raising maintenance costs.

These issues don’t just slow production—they compromise product quality and increase the risk of machine damage.

How the Right Rubber Roller Reduces Machine Downtime

Selecting a properly engineered rubber roller goes beyond just maintaining speed—it supports safer, more reliable production. Here’s how:

- Reduces Misalignment: Prevents drift during material handling, which helps avoid paper jams or printing errors.

- Ensures Smooth Material Flow: Maintains consistent grip, even at high RPMs or with variable material types.

- Lowers Machine Maintenance: High-quality rollers reduce roller-related stress on bearings, shafts, and mounts.

- Improves Throughput Reliability: Keeps machines online longer with less unplanned intervention from technicians.

For plants working on lean schedules or 24/7 shifts, this can mean the difference between meeting delivery targets or missing them.

What Sets Siva Rollers Apart from Other Manufacturers

With over two decades of experience and a reputation built within India’s major manufacturing hubs, Siva Rollers stands out for reasons that matter to buyers and engineers:

- Trusted in Industrial Clusters: Frequently chosen by OEMs and suppliers in Gujarat, Maharashtra, Tamil Nadu, and beyond.

- Quick Quotes and Communication: Engineers and procurement teams can count on fast responses and transparent pricing.

- Stable Product Quality: Batch-to-batch consistency for buyers who depend on repeatability across large runs.

- Long-Term Client Relationships: Many clients have worked with Siva Rollers for over 10 years—trust earned through performance.

Rubber rollers may not be the most visible part of your machine, but they play a pivotal role in daily output. Their quality determines how smoothly your materials move, how reliably your machines run, and how much maintenance your operations require.

Siva Rollers understands this. That’s why they’ve committed to producing industrial-grade rubber rollers that Indian industries can rely on—rollers that support your targets, not stand in the way of them.

If your plant is evaluating new roller suppliers, or if you’re seeing too many issues with your current rollers, it’s worth considering a manufacturer with real-world experience and local credibility.

For durable, factory-tested Rubber Rollers in India, Siva Rollers offers a combination of expertise, reliability, and service that’s hard to match.

Get in Touch with Siva Rollers

Looking for a trusted rubber roller manufacturer India?

Whether you need a custom-built roller or want to refurbish your existing one, we’re here to help. We offer fast service, quality products, and expert guidance to keep your operations running efficiently.

FAQs

A rubber roller is used to press, guide, or transfer materials in machines. It helps maintain grip, pressure, and motion control across a range of applications like printing, textile processing, packaging, and sheet handling.

Rubber roller are widely used in industries such as:

- Printing (for ink transfer and paper feed)

- Textile (for fabric processing and guiding)

- Packaging (for lamination and sealing)

- Steel and metal (for guiding sheets without damaging surfaces)

- Paper and pulp (for coating and slitting operations)

Some common types include:

- Printing rubber rollers

- Industrial conveyor rollers

- PU-coated rollers

- Ebonite rollers

- Nip rollers

Each type is made for specific machinery and process needs.

Roller life depends on usage, material, and working conditions. On average, a high-quality rubber roller from a reliable manufacturer like Siva Rollers can last several months to a few years under regular industrial use.

Common reasons include:

- Poor-quality rubber compounds

- Exposure to excessive heat or chemicals

- Overloading or misalignment in machines

- Low maintenance or incorrect installation

You should consider the following:

- Type of material being processed

- Required hardness and grip

- Machine speed and load

- Resistance to temperature, pressure, and chemicals

It’s best to consult with an experienced Rubber Roller Manufacturer in India like Siva Rollers to get the right match.

Yes, many manufacturers including Siva Rollers offer custom-designed rubber rollers tailored to your machine dimensions, rubber hardness, and industrial application.

Siva Rollers is trusted for:

- Consistent quality in every batch

- Use of durable rubber materials

- Fast communication and quoting

- Deep understanding of Indian industrial machinery

These factors make them a preferred supplier of Rubber Rollers in India.

In many cases, yes. Rubber roller provide better grip and surface protection compared to bare metal rollers. Always consult with your machinery engineer or supplier to confirm compatibility.

You can source rubber roller directly from Siva Rollers, based in Ahmedabad, Gujarat. They manufacture and supply industrial-grade rubber rollers across India for use in printing, textile, packaging, and other sectors.