Printing Rubber Roller in India

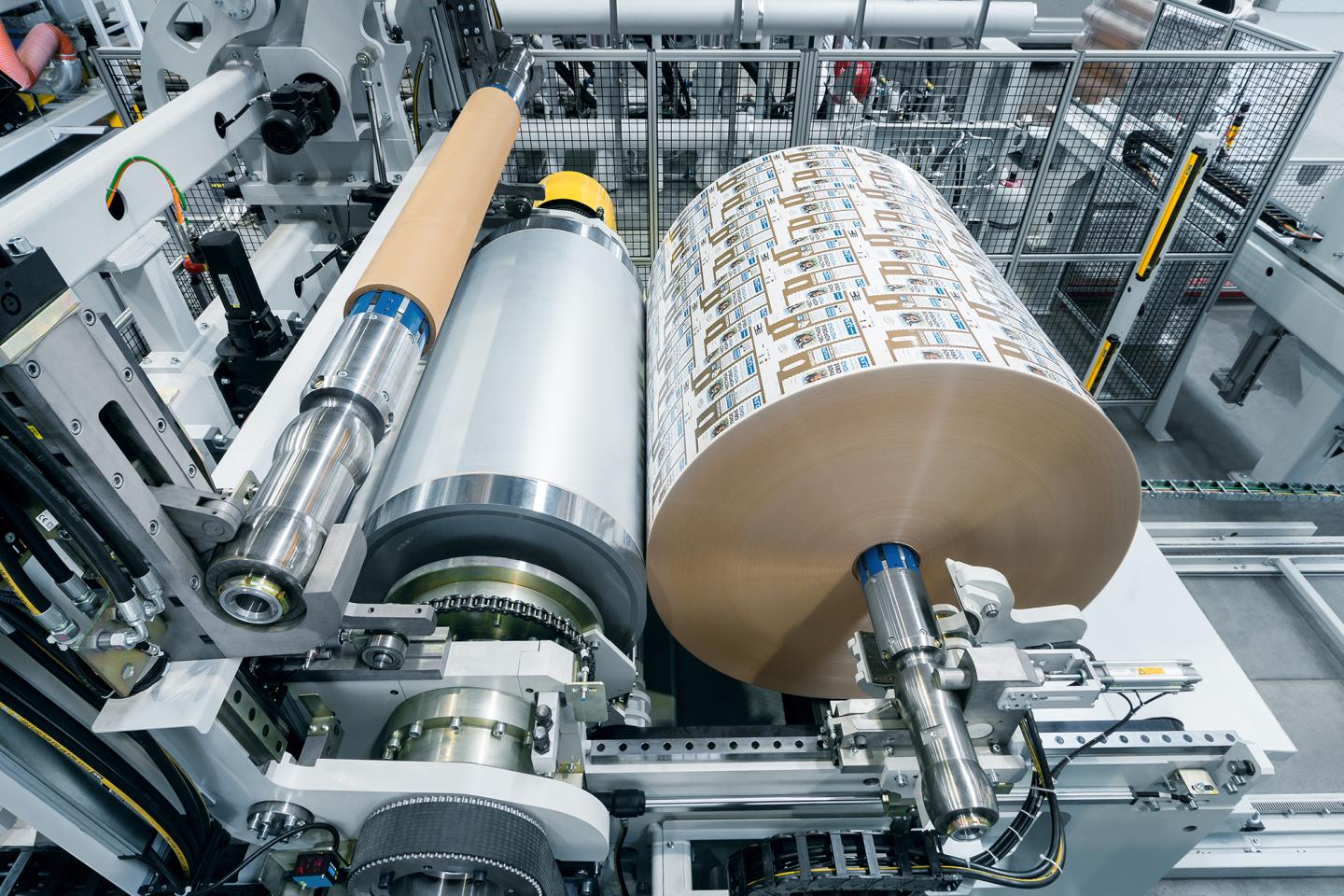

Printing rubber rollers are central to the performance, reliability, and output quality of industrial printing operations. Whether it’s flexographic, gravure, or offset printing, the quality of rollers directly impacts print registration, ink distribution, and equipment longevity.

Based in Ahmedabad, India, Siva Roller is a trusted name in the manufacturing of printing rubber roller, rubber roller, and other industrial roller. With decades of domain experience, modern infrastructure, and a commitment to quality, Siva Roller supports OEMs, printers, and equipment integrators across India and global markets.

What Are Printing Rubber Roller?

They typically comprise a metal core—such as mild steel or stainless steel—overlaid with specialized rubber compounds like NBR, EPDM, or Silicone, depending on printing type and ink chemistry. Custom rubber roller for printing may also feature grooved profiles, specific surface finishes, and tailored hardness for niche applications.

Industry Applications of Printing Roller

Surface Finishes & Custom Engineering Capabilities

Available Surface Treatments:

- Ground, polished, or matte finishes

- Groove patterns: diamond, spiral, or cross-hatch

- Anti-static coatings

- Chrome plating for corrosion protection

Customization Includes:

- Roller lengths up to 4,000 mm

- Specific rubber layer thicknesses

- Balancing for high-speed applications

- Journal modifications or custom shaft designs

Every printing rubber roller is balanced for low vibration, optimized for ink compatibility, and built for uniformity throughout its lifecycle.

How Siva Rollers Ensures Performance Consistency

- Batch Consistency Testing: Each batch of rubber compound is tested for Shore hardness, elongation, and abrasion.

- Thermal and Chemical Resistance: Rollers are subjected to simulated environments mimicking actual press conditions.

- Ink Transfer Quality: Specially designed test rigs ensure smooth and even ink distribution.

- Concentricity & Dynamic Balancing: Ensures smooth operation and minimal mechanical stress on printing machines.

These issues don’t just slow production—they compromise product quality and increase the risk of machine damage.

How the Right Rubber Roller Reduces Machine Downtime

Selecting a properly engineered rubber roller goes beyond just maintaining speed—it supports safer, more reliable production. Here’s how:

- Reduces Misalignment: Prevents drift during material handling, which helps avoid paper jams or printing errors.

- Ensures Smooth Material Flow: Maintains consistent grip, even at high RPMs or with variable material types.

- Lowers Machine Maintenance: High-quality rollers reduce roller-related stress on bearings, shafts, and mounts.

- Improves Throughput Reliability: Keeps machines online longer with less unplanned intervention from technicians.

Global Supply Capability & Export-Ready Production

- Export-Grade Packaging: Customized wooden crates, moisture-barrier wrapping, and secure shaft locking for long transits.

- Document Compliance: All export shipments include Material Test Certificates (MTC), batch reports, and origin certificates if needed.

- International Reach: Rollers supplied to Middle East, Southeast Asia, Africa, and parts of Europe.

Common Challenges Solved by Siva Rollers

- Ink Smearing & Uneven Transfer: Solved via optimized rubber compound selection and surface roughness tuning.

- Roller Vibrations: Dynamic balancing and journal reengineering eliminate vibration at high RPMs.

- Premature Roller Wear: Correct material pairing and compounding ensure longer life even under aggressive inks and solvents.

Let’s Build Your Printing Roller Solution

Siva Roller is more than a supplier—we are your precision partner in industrial printing performance. From custom rubber roller to high-speed printing applications, we bring deep technical insight, consistent quality, and responsive service.

✔ Contact us to discuss your specific roller requirements

✔ Get a quote for standard or custom printing rollers

✔ Re-engineer or refurbish your existing rollers for better performance

FAQs

A printing rubber roller is used to transfer ink or substrates in various printing systems such as flexographic, gravure, offset, and textile printing. It ensures even ink distribution and helps achieve precise image reproduction on different materials like paper, plastic film, and fabric.

A rubber roller is a broad category used in many industries (like packaging, textiles, steel, etc.), while a printing roller is a specific type of rubber roller designed for ink transfer in printing applications. Printing rollers require higher precision, ink compatibility, and surface finish standards.

Nitrile (NBR), EPDM, and Silicone rubber are commonly used for printing rollers. The choice depends on ink type, operating temperature, and required chemical resistance. NBR is ideal for solvent-based inks, while EPDM suits water-based inks.

Choosing the right printing roller depends on your machine type, printing speed, ink type, substrate material, and required print quality. It’s best to consult a manufacturer like Siva Roller who offers customization based on load, hardness, surface finish, and size.

Yes, printing rubber rollers can be refurbished by regrinding, re-rubberizing, and rebalancing the core. Refurbishment extends roller life and reduces replacement costs. Siva Roller provides professional recoating and repair services with quality control testing.

What are the signs of a worn-out printing roller?

Absolutely. Siva Roller specializes in custom rubber rollers for printing, tailored to non-standard sizes, groove profiles, rubber compounds, and core materials to suit legacy and advanced printing machines.

Printing rubber rollers are widely used in:

- Packaging & Label Printing

- Textile Printing

- Newspaper and Commercial Offset

- Corrugated Box Manufacturing

- Wallpaper & Decorative Printing

In many cases, yes. Rubber roller provide better grip and surface protection compared to bare metal rollers. Always consult with your machinery engineer or supplier to confirm compatibility.

You can source rubber roller directly from Siva Rollers, based in Ahmedabad, Gujarat. They manufacture and supply industrial-grade rubber rollers across India for use in printing, textile, packaging, and other sectors.