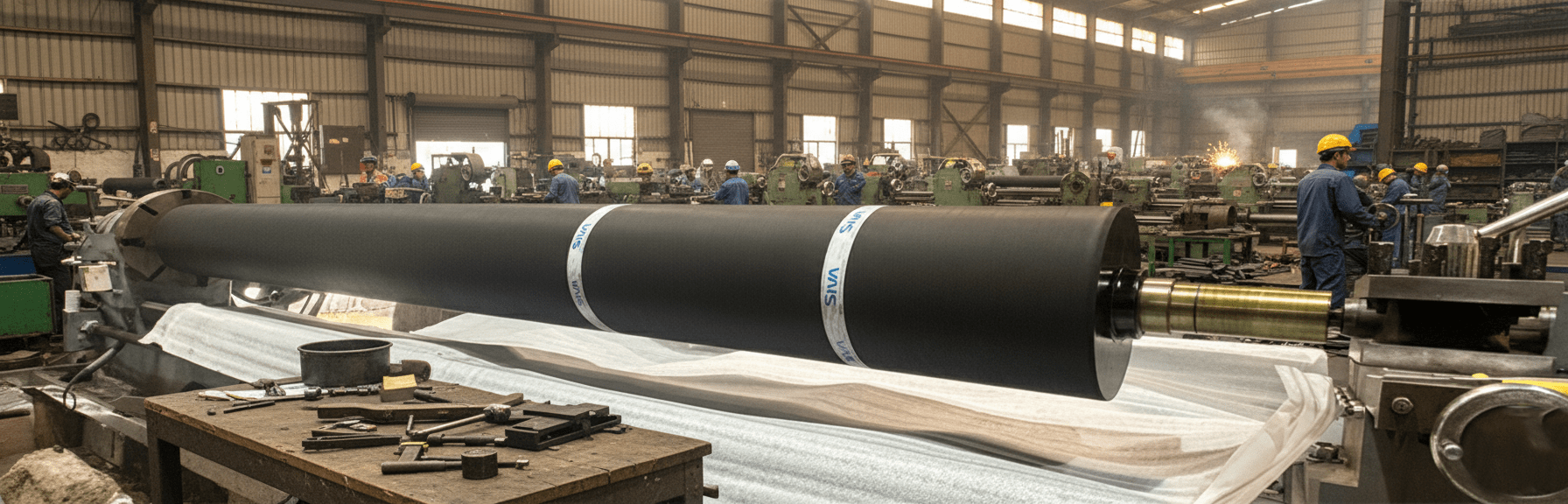

Rubber Roller Manufacturer in Gujarat: Siva Rollers, Your Trusted Partner for Industrial Rollers

Welcome to Siva Rollers, the leading Rubber Roller Manufacturer in Gujarat, setting the standard for precision engineering and unmatched durability. If you are searching for a reliable Rubber Roller in Gujarat to minimize downtime and maximize operational efficiency, your search ends here. Located strategically to serve the industrial heartlands of Ahmedabad and Surat, we specialize in delivering precision, durability, and immediate local support. Our value proposition is clear: we manufacture industrial rollers that guarantee a 2x longer lifespan than standard options, providing a clear competitive advantage in performance and cost of ownership. Request a FREE Technical Consultation on Roller Lifespan and Coating Material today.

Need a durable, high-precision industrial rubber roller?

Our Advanced Manufacturing Process

To truly understand why Siva Rollers delivers a superior Rubber Roller in Gujarat, you must understand the precision that goes into every stage of manufacturing. We control the entire process, from core preparation to final finishing, ensuring every industrial rubber roller leaving our facility meets global standards for concentricity and wear resistance. This commitment to technical excellence is why we are the preferred Rubber Roller Manufacturer in Gujarat for high-specification industries.

Precision Core Preparation and CNC Machining

The integrity of the roller starts with its core. We utilize advanced CNC Machining capabilities to ensure roller shafts and cores are perfectly true, parallel, and concentric. Any deviation at this stage leads to vibration, poor performance, and premature failure later on. Our process includes:

- Dimensional Verification : Confirming core dimensions meet exact engineering blueprints.

- Surface Preparation: Sandblasting and chemical cleaning to ensure a flawless bonding surface.

- Keyway and Bearing Alignment: Precise machining of keyways and journals for perfect fitment in your machinery.

Proprietary Polymer Bonding & Curing

The critical difference in our product is the bond between the metal core and the rubber compound. We utilize a proprietary, high-strength chemical adhesive system to create a permanent, non-peeling bond. This directly addresses the common industry pain point of rubber failure.

- Custom Compound Mixing: : Rubber compounds (Nitrile, EPDM, Silicone, PU) are mixed in-house and customized based on the end-use environment (e.g., high heat in Surat, solvent exposure in Vapi).

- Autoclave Curing Rollers are cured under precisely controlled temperature and pressure in large industrial autoclaves, ensuring the polymer structure achieves maximum cross-linking for optimal hardness and durability—a critical step that defines the roller’s eventual lifespan.

Why Siva Rollers is the Best Rubber Roller Manufacturer in Gujarat

Choosing the right Rubber Roller Manufacturer in Gujarat is not just about price; it’s about partnership, localized service, and understanding the specific operational demands of the region’s diverse industries. Siva Rollers is recognized as the Leading Rubber Roller Supplier in Gujarat because we offer a unique blend of global manufacturing excellence with truly local accessibility and support. Our compounds are chemically optimized to resist the solvents, heat, and pressures common in Gujarat’s processing plants, unlike mass-market rollers that quickly degrade.

We understand that a failing roller can shut down an entire production line, leading to massive financial losses. Our mission is to eliminate that risk through superior compound formulation, meticulous craftsmanship, and fast-turnaround maintenance services right here in Gujarat.

We used to replace our lamination rollers in Surat every six months. Since switching to Siva Rollers’ EPDM compound, we haven’t had a failure in over 18 months. Their local support is simply unmatched.” – Mr. Kirit Patel, Operations Manager, Textile Processing Unit, Surat.

Unmatched Local Service Across Key Industrial Hubs

Our operational footprint ensures that whether you require a new industrial rubber roller in Vapi or a PU roller re-coating in Rajkot, a Siva Rollers expert is always within easy reach. We provide specialized Custom Rubber Roller Manufacturing tailored to the unique industrial ecosystem of each major city:

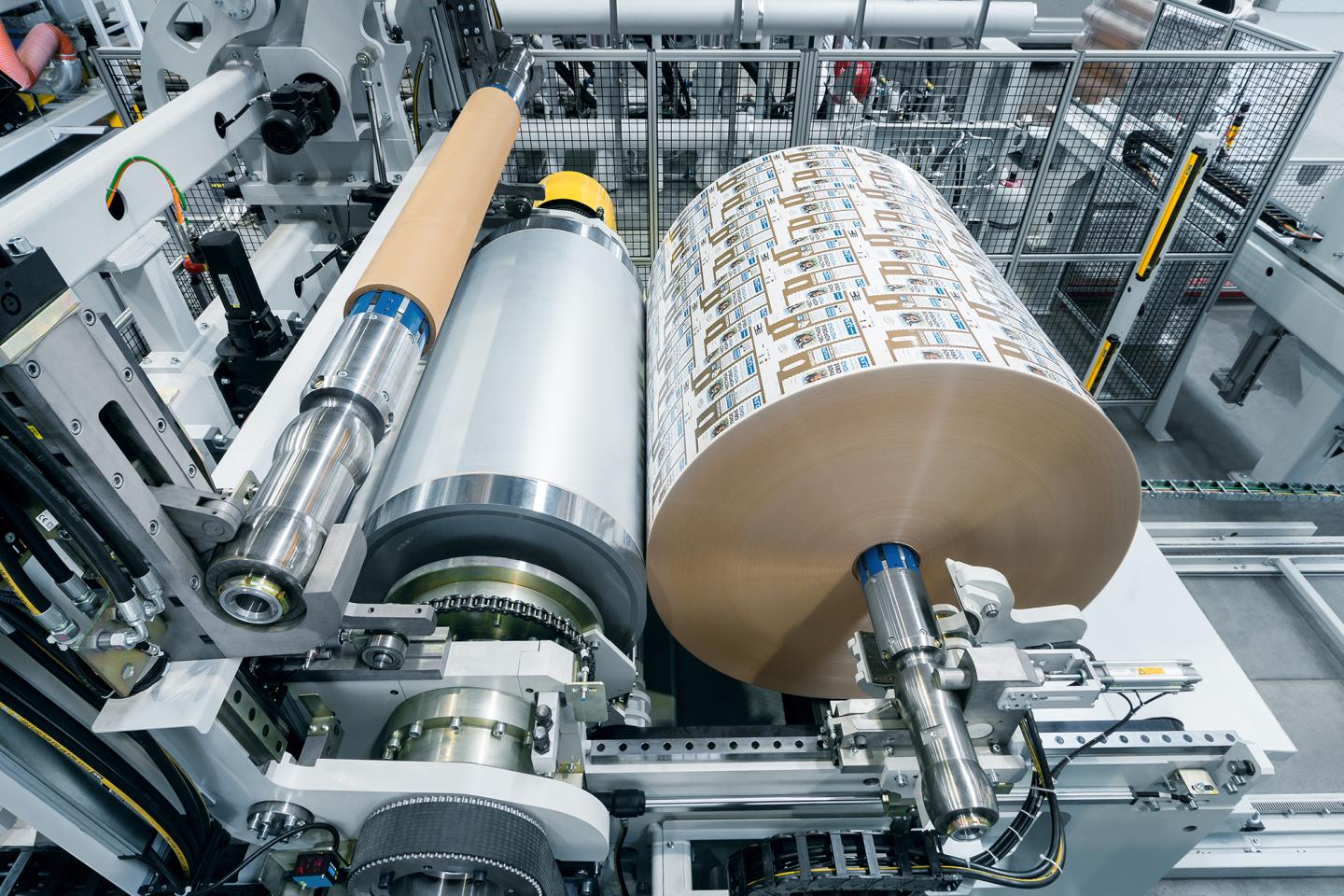

- As the state's economic powerhouse, we supply high-precision printing rollers and packaging rollers for fast-moving consumer goods (FMCG) and paper industries, focusing on high-speed, dynamic balancing for flawless operation.

The global textile hub. We are specialists in textile rollers and squeezing rollers with specific compounds (like Nitrile and Silicone) designed to withstand high-temperature dyeing and aggressive chemical lamination processes.

Serving the engineering and automotive sectors, our specialty lies in heavy-duty steel rollers and high-abrasion resistant PU rollers, providing competitive Rajkot Roller Price advantages for bulk buyers.

Supporting the ship-breaking and heavy machinery sectors with resilient, wear-resistant Ebonite and hard-coated rollers built for extreme load capacity.

Catering to the dense chemical and pharmaceutical clusters, our focus is on EPDM and Silicone rollers offering superior acid, alkali, and high-purity solvent resistance, ensuring compliance and long operational life.

Industry We Served

Rubber Roller Price in India: Get Your Competitive Quote Today

When searching for Rubber Roller Price in India, you will encounter a wide range of quotes. At Siva Rollers, we believe in transparent pricing that reflects the true, long-term value of a superior product, not just the initial purchase cost. We provide a competitive Rubber Roller Price in India by optimizing our local manufacturing processes and cutting down on national logistics costs, passing the savings directly to our Gujarat-based partners.

Tired of rollers failing every 6 months? Our compound guarantees a 2x longer lifespan, solving the critical pain point of premature wear that forces customers to switch suppliers.

The Siva Rollers Quality Guarantee: Value that Beats the Price

Our commitment to quality means that while our initial quote might reflect the use of premium-grade polymers and technical precision, the total cost of ownership (TCO) is significantly lower than that of any competitor. This is the Siva Rollers Guarantee:

- Lower Downtime: Our precision roller coatings and dynamic balancing guarantee vibration-free operation, drastically reducing the risk of unexpected production stops.

- 10+ Year Lifespan for Core Components: Unlike suppliers who use subpar cores, our roller cores are built for extreme durability, requiring only routine re-coating, saving you the cost of full roller replacement.

- First-Time Precision: Our CNC Machining capabilities ensure perfect concentricity and dimensional stability right out of the box, eliminating costly installation delays and material waste.

- Full Certification: Every roller meets rigorous ISO 9001 and global industry standards, providing the B2B trust signals and compliance assurance your business requires.

- Zero Peeling, Guaranteed: We use proprietary bonding agents that chemically fuse the rubber compound to the roller core, explicitly addressing the common pain point of rubber peeling under high-stress operation.

Precision Custom Rubber Roller Manufacturing & Re-Coating Services

As a highly specialized Rubber Roller Manufacturer India, our technical capabilities extend far beyond standard catalogue products. We excel in Custom Rubber Roller Manufacturing, reverse-engineering unique roller specifications, and performing high-grade re-coating services that often exceed the performance of the original equipment.

We utilize advanced CNC Machining for core preparation, ensuring perfect parallelism and geometric accuracy. Crucially, every high-speed roller undergoes Dynamic Balancing in our facility to eliminate operational vibrations that cause product defects, premature bearing failure, and machinery wear—a vital step often skipped by less specialized Rubber Roller Suppliers in Gujarat.

Roller Types for Gujarat's Key Industries

We work closely with clients in Ahmedabad, Surat, and Rajkot to determine the optimal roller compound and hardness (measured in Shore A/D) required for specific process environments. Our technical team ensures the precise pairing of roller type to local sectoral needs:

Roller Type | Primary Material(s) | Key Industry Application (Gujarat) | Unique Benefit & Differentiation Strategy |

Textile & Squeezing Rollers | Nitrile, EPDM, Silicone | Surat Textile Lamination, Dyeing & Finishing, Printing | Differentiation: EPDM offers superior chemical resistance to aggressive textile chemicals used in Surat, ensuring the roller maintains optimal durometer and dimensional stability. |

Printing & Gravure Rollers | Nitrile, Polyurethane (PU) | Ahmedabad/Vapi Printing, Packaging & Film Industries | Differentiation: Our PU coating provides exceptional abrasion and cut resistance, crucial for high-speed printing presses and guaranteeing low print quality issues. |

Industrial Coating Rollers | Silicone, Natural Rubber | Pharmaceutical, Food Processing (Vapi, Vadodara) | Differentiation: High-purity Silicone coating guarantees non-toxicity and high-release properties for specialized adhesive or solvent application in critical chemical plants. |

Laminating & Pull Rollers | Ebonite, Neoprene | Steel Rolling Mills, Packaging, Heavy Engineering (Rajkot, Bhavnagar) | Differentiation: Ebonite (hard rubber) offers unparalleled structural rigidity and heat tolerance required for heavy-duty material handling and high-temperature laminating processes. |

Mining & Conveyor Rollers | Natural Rubber, Neoprene | Heavy Duty Conveyance, Material Handling (Bhavnagar, Vapi) | Differentiation: Our specialized Natural Rubber compound provides maximum resilience and high rebound, minimizing product damage and absorbing impact loads in bulk material transport. |

Detail on Materials: Meeting Gujarat’s Chemical Needs

We don’t just supply rubber rollers; we supply engineered solutions.

Nitrile Rollers (NBR)

Ideal for general-purpose oil and solvent resistance, perfect for printing and packaging inks used throughout Ahmedabad and Vadodara.

EPDM Rollers

Crucial for chemical plants in Vapi and Vadodara, offering superior resistance to hot water, steam, and polar solvents. This is essential where rollers are exposed to strong cleaning agents or high-humidity environments.

Silicone Rollers

- Unbeatable high-heat resistance and excellent release properties. Used for extreme temperature applications (up to 250°C) such as specialized plastic processing and high-speed textile roller lamination in Surat.

PU Rollers (Polyurethane)

Offers the highest load-bearing capacity and cut resistance, making them perfect for applications requiring extreme durability, like heavy-duty machinery in Rajkot.

The Final Touch: Dynamic Balancing and Surface Finishing

After the curing process, the rubber must be ground to final specifications. We employ precision grinding techniques to achieve the required surface finish (smooth, grooved, or crowned) and dimensional accuracy.

- Surface Finish (Ra/Rz): Tailored grinding ensures the exact surface roughness (Ra/Rz) required for the application, whether it’s an ultra-smooth finish for high-fidelity printing or a textured surface for maximum grip.

- Crowning/Tapering: We precision-grind rollers to specific crowns or tapers as required by complex machinery to ensure even pressure distribution across the roller’s face, preventing material creasing and uneven wear.

Maximizing Roller Lifespan: Maintenance, Re-coating & Warranty

The true value of choosing Siva Rollers as your Rubber Roller Manufacturer in Gujarat is the support we offer over the roller’s operational life. Our long-term service programs drastically reduce your total cost of ownership (TCO) compared to buying new rollers repeatedly.

Understanding Durometer and Application-Specific Hardness

The durometer (hardness) of the roller is the single most important factor determining its performance and lifespan. We use Shore A/D testing to ensure the roller coating matches the specified hardness required for the exact application:

- Soft Rollers (20-45 Shore A): Excellent for transfer and lamination applications where conformability and even pressure are vital (e.g., fine art printing).

- Medium Rollers (50-75 Shore A): General-purpose use, including standard web control and squeezing rollers in the textile roller industry.

- Hard Rollers (80+ Shore A / Shore D): Used for load-bearing, feed, or guide rollers in heavy machinery, particularly common in the Rajkot engineering sector.

Incorrect durometer selection is a major cause of premature roller failure, which is why our technical consultation is so valuable before you finalize your Rubber Roller Buy.

Comprehensive Roller Audit and Predictive Maintenance Program

We offer a regional roller audit service for our clients in Gujarat. A Siva Rollers technician can visit your facility (in Ahmedabad, Surat, Vadodara, etc.) to:

- Inspect Rollers : Check durometer, surface quality, and concentricity.

- Identify Wear Patterns: Pinpoint operational issues leading to early wear.

- Predict Service Life : Provide a clear timeline for when rollers will need re-coating, allowing you to schedule maintenance during planned downtime.

This predictive approach prevents unexpected shutdowns, translating directly into operational savings that far outweigh the initial Rajkot Roller Price or Rubber Roller Price in India.

Final Step: Secure Your Production Line Today

Don’t settle for constant roller replacement and frustrating downtime. Upgrade to the precision and durability guaranteed by the premier Rubber Roller Manufacturer in Gujarat. Siva Rollers is your local solution for superior quality, competitive value, and technical expertise across Ahmedabad, Surat, and Rajkot.

Stop searching. Start producing.

Call us now to speak with a Roller Specialist: +91 75070 10009

Siva Rollers: Engineering Durability. Delivered Locally.

FAQs

The lifespan varies significantly based on material and use. A standard industrial rubber roller may last 6-12 months. However, Siva Rollers’ high-grade compounds and precision coatings are engineered to last 18-36 months between re-coatings, offering dramatically increased operational longevity.

The most accurate Rubber Roller Price is achieved through a technical consultation. We need to know the roller's dimensions (diameter, length), the operating environment (temperature, chemicals, speed), and the desired coating material (Nitrile, EPDM, PU, etc.). Contact us directly for a competitive, no-obligation quote.

Yes, absolutely. Our specialty is in Custom Rubber Roller Manufacturing. We can reverse-engineer rollers from technical drawings or even a worn-out sample, utilizing our CNC Machining and polymer expertise to create a dimensionally perfect replacement.

Dynamic Balancing is critical for any roller operating over 300 RPM. Without it, the roller will vibrate, leading to roller peeling, poor product quality (like streaking in printing), and premature failure of machine bearings. All Siva Rollers for high-speed applications undergo mandatory dynamic balancing.

Our local presence allows us to offer some of the fastest turnaround times in the region. Standard re-coating service typically takes 3-7 working days, minimizing your production downtime. Urgent services can be arranged upon request.