Ebonite Rollers India’s Trusted Manufacturer

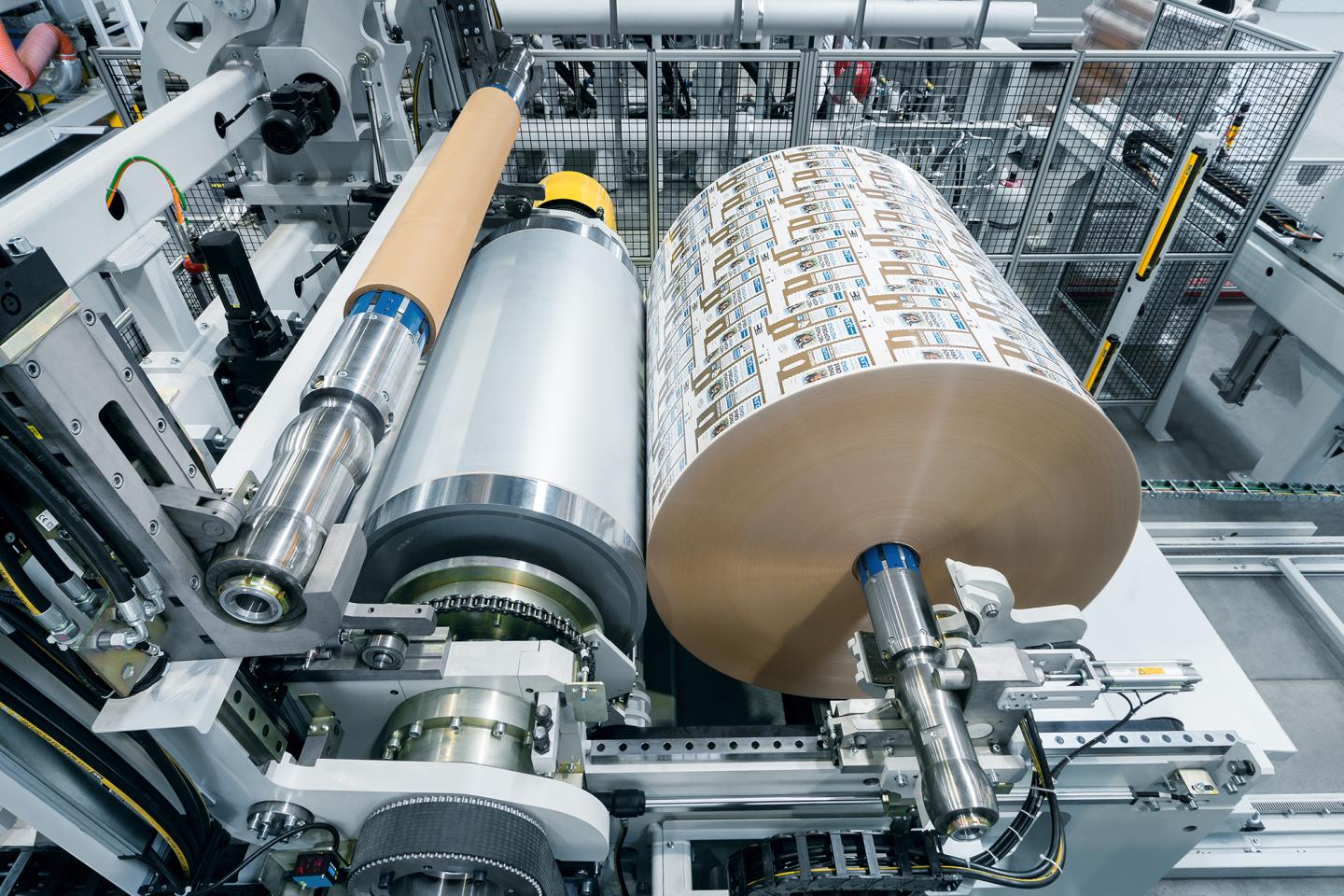

In the world of high-speed industrial operations, consistency and reliability are not just goals—they are absolute necessities. The flawless movement of material, the perfect application of pressure, and the uniform transfer of inks or chemicals depend entirely on specialized components built for demanding environments. At the core of this precision machinery lies the Ebonite Roller.

Ebonite Roller are specialized, heavy-duty components designed to withstand extreme conditions, from high temperatures and abrasive chemicals to immense pressure and continuous high-speed rotation. Their purpose is simple yet critical: to ensure smooth, precise, and consistent operations across countless manufacturing processes.

For any machinery involving calendaring, printing, feeding, or material guiding, the roller is the component that defines the final output quality. A poorly manufactured roller leads to vibrations, uneven pressure, and costly downtime.

Behind every high-speed printing press or paper machine, an Ebonite Roller ensures flawless motion. If you are an industrial buyer, plant manager, or procurement specialist seeking durability and precision, understanding the quality of your rollers is the first step toward optimizing your entire production line.

We guarantee a response from an expert engineer within 24 hours

About Siva Rollers – Trusted Ebonite Roller Manufacturer in India

For over a decade, Siva Rollers has stood as a hallmark of manufacturing excellence in the industrial roller segment. As a leading Ebonite Roller Manufacturer in India, we have built our reputation on an unyielding commitment to precision engineering, premium materials, and deep customer trust.

Our expertise is rooted in more than just rubber; it’s rooted in application. We understand that a roller is not a generic part, but a custom solution tuned to the specific chemical, thermal, and mechanical stresses of your industry. Our experience spans diverse sectors—from the delicate requirements of film packaging to the heavy-duty demands of the steel industry.

We emphasize manufacturing excellence through a rigorous, multi-stage quality control process. This ensures that every roller leaving our facility in India meets global standards for hardness, concentricity, and dynamic balance.

Siva Rollers is proud to serve hundreds of clients across India and a growing number of global partners. When you choose us, you are not just acquiring a roller; you are investing in a long-term partnership with a highly authoritative and trustworthy manufacturer dedicated to reducing your operational costs and maximizing your output.

What is an Ebonite Roller? Defining the Industrial Gold Standard

Before buying, it’s essential to understand exactly what makes Ebonite the material of choice for demanding industrial applications.

Defining Ebonite Material

Ebonite, often referred to as hard rubber or vulcanite, is a material created through the process of extensive vulcanization of natural or synthetic rubber. This process involves adding a high percentage of sulfur (typically 25% to 40%) to the rubber compound and subjecting it to high heat and pressure for a prolonged period. This intensive curing process fundamentally changes the molecular structure of the rubber.

The result is a material that is completely non-elastic, extremely dense, and possesses properties similar to a hard plastic or thermoset polymer, yet retains the superior damping and adhesion qualities inherent to rubber.

Why Industries Prefer Ebonite Rollers Over PU or Metal

While polyurethane (PU) and metal rollers have their place, industries prefer Ebonite Rollers for certain critical applications due to a unique combination of advantages:

- Superior Chemical and Corrosion Resistance: Ebonite is virtually immune to attack from many aggressive chemicals, acids, and alkalis, making it ideal for the chemical, plating, and textile dyeing industries.

- Exceptional Hardness: Ebonite offers a very high shore hardness (typically up to 90-100 Shore D), providing a rigid, dimensionally stable surface that prevents deformation under immense load.

- Electrical Insulation: Hard rubber is a superb electrical insulator, a critical factor in processes like electrostatic printing or certain material handling applications.

- Damping: Unlike metal, the vulcanized hard rubber base provides a degree of vibration damping, which is crucial for achieving high surface quality and quiet operation in high-speed machines.

If you’re looking for a roller material that combines the rigidity of plastic with the corrosion resistance of advanced compounds, Ebonite is the superior choice.

Key Features and Advantages of Siva Ebonite Rollers

Every High-Quality Ebonite Roller manufactured by Siva Rollers is engineered to deliver peak performance and reliability, directly translating to lower maintenance costs and maximized uptime for your facility.

Here are the distinct features and tangible advantages of our Industrial Ebonite Rollers:

High Hardness and Smooth Surface

Our proprietary vulcanization process ensures a uniform hardness across the roller face. We utilize state-of-the-art precision grinding and polishing techniques to achieve a mirror-like finish (low surface roughness/Ra value). This is vital for applications requiring non-marking transport, such as film or paper production.

Chemical and Corrosion Resistance

The high sulfur content and tight cross-linking in our ebonite compound make the rollers highly resistant to organic solvents, acids, and bleaching agents. This dramatically extends the operational life of the roller in highly corrosive environments, unlike standard synthetic rubber.

Perfect Dynamic Balance for High-Speed Machines

For machinery running at high RPMs, imbalance is the leading cause of vibration, bearing wear, and print defects. Each of our Ebonite Rollers for Printing & Packaging applications is dynamically balanced to extremely tight tolerances, guaranteeing silent, vibration-free operation even at maximum speed.

Excellent Grip and Wear Resistance

Despite its hardness, ebonite provides exceptional coefficient of friction when required, offering reliable feeding and guiding capabilities. Furthermore, its density ensures superior wear resistance, meaning longer intervals between regrinding or replacement.

Custom Size and Coating Options

We specialize in custom engineering. We offer a full range of roller sizes and diameters, shaft designs (including complex mandrels), and customized coatings to meet non-standard requirements. This adaptability makes us the preferred Rubber Roller Manufacturer in India for specialized machinery.

Long Operational Life

The combination of premium-grade raw materials, meticulous compounding, and controlled vulcanization results in a finished product with an exceptionally long operational lifespan, reducing your Total Cost of Ownership (TCO).

👉 Each Ebonite Roller by Siva Rollers undergoes precision finishing for perfect balance and performance, ensuring your machines run smoother and longer.

Industries We Serve with Ebonite Roller Excellence

How Ebonite Rollers Improve Production Efficiency

Choosing the right Ebonite Roller is one of the most direct ways to impact your facility’s production efficiency and profitability. This is where the helpful content element of our brand becomes clear.

Quality Reduces Downtime: The primary enemy of industrial efficiency is unplanned downtime. Low-quality, cheap rollers often suffer from premature surface cracking, chemical swelling, or rapid concentricity loss, leading to frequent machine shutdowns for roller replacement or re-grinding. Siva Rollers’ High-Quality Ebonite Rollers are built for resilience, drastically extending the mean time between failures (MTBF).

Consistency Means Less Waste: In processes like multi-colour printing or film lamination, uneven roller pressure results in wasted material, flawed products, and rejected batches. Our rollers’ guaranteed dynamic balance and dimensional stability ensure consistent pressure distribution across the full width, minimizing material waste and maximizing first-pass yield.

Reduced Maintenance Cost: Because our ebonite compound resists wear and chemical degradation, the need for costly and time-consuming maintenance, such as frequent regrinding or bearing replacement (due to imbalance), is significantly reduced. This delivers substantial long-term savings.

Why Choose Siva Rollers – Your Partner in Roller Technology

When you are looking to Buy Ebonite Roller Online or secure a bulk manufacturing contract, the supplier’s commitment to quality and service is as important as the product itself. Siva Rollers offers distinct competitive advantages that set us apart as the premier Rubber Roller Manufacturer in India.

10+ Years of Manufacturing Excellence

Our decade of experience has been dedicated solely to industrial rollers. This deep, focused expertise means we understand the subtle differences between compounds, the precise tolerances needed for high-speed machines, and the unique challenges faced by each sector we serve.

Skilled Engineers and Modern Infrastructure

Our manufacturing facility is equipped with modern infrastructure, including CNC grinding machines, dynamic balancing instruments, and advanced curing ovens. Our skilled engineers and technicians oversee every step, ensuring process control is maintained at the highest level—from mixing the raw rubber compound to the final polishing.

Customized Roller Design and Coating

We don’t believe in a one-size-fits-all approach. Whether you need an oversized Industrial Ebonite Roller for a paper mill or a small, chemically inert roller for a packaging machine, we provide tailor-made solutions. This bespoke approach guarantees optimal performance for your specific equipment.

Fast Delivery and Technical Support

We maintain efficient production timelines and logistics networks to ensure fast, reliable delivery across India and for our international clients. Furthermore, our dedicated technical support team is available to assist with installation queries, operational optimization, and maintenance guidance, ensuring true after-sales service.

Trust-Building Elements:

- In-House Quality Control: We operate an in-house quality assurance laboratory where every batch is tested for Shore hardness, compound consistency, and chemical resistance before production begins.

- Transparency: We provide material certification and testing reports upon request, offering complete traceability and accountability.

- Long-Term Client Partnerships: Our focus is on building long-term relationships, demonstrated by our dedicated account management and consistent supply to India’s leading industrial houses.

Common Problems in Low-Quality Rollers (and How Siva Rollers Solves Them)

The market is flooded with low-cost options, but a cheap roller often proves to be the most expensive purchase in the long run. Recognizing the flaws of poor manufacturing is key to preventing operational disaster.

Common Low-Quality Roller Problems | How Siva Rollers Solves the Issue |

Uneven Coating Thickness | Precision Grinding: Our multi-stage grinding ensures dimensional accuracy within microns, leading to absolutely uniform pressure distribution. |

Surface Cracks or Pitting | Premium-Grade Ebonite: We use certified, high-purity rubber and sulfur compounds, ensuring the hard rubber layer is dense, resilient, and resists premature cracking. |

High Vibration at Speed | Dynamic Balancing: Every high-speed Printing Ebonite Roller is dynamically balanced, eliminating the mass distribution errors that cause destructive machine vibration. |

Poor Chemical Resistance | Formulation Control: Compounds are precisely formulated to meet specific chemical resistance requirements (e.g., acid or solvent resistance), preventing swelling and softening. |

Core Delamination | Adhesion Expertise: We utilize specialized surface preparation and bonding agents to ensure an unbreakable bond between the hard rubber and the metal core. |

Build Authority: Our rollers are trusted by 500+ industrial units across India for our consistent quality and commitment to performance longevity.

Quality Testing & Manufacturing Process for Ebonite Excellence

The superior quality of a Siva Rollers Ebonite Roller is not accidental; it is the result of a meticulously controlled and standardized manufacturing process that reflects the highest E-E-A-T standards.

The Manufacturing Process (From Core to Coating)

- Core Inspection: The process begins with the careful inspection of the metal core (mandrel). It must be perfectly cleaned, blasted, and prepared to ensure maximum adhesion of the ebonite compound.

- Compounding & Vulcanization: We use premium-grade natural or synthetic rubber, mixing it precisely with sulfur and other vulcanizing agents according to the final application requirements. The compound is then applied to the core and cured in a high-pressure autoclave. The extended curing time is vital for achieving the ultra-hard, non-elastic state of true ebonite.

- Precision Machining: After curing, the hard rubber shell is machined using advanced CNC lathes and grinding equipment. This stage ensures the roller diameter, run-out, and concentricity are accurate to microns, essential for high-speed use.

- Final Surface Finishing: The surface is polished to the required smoothness (Ra value), ensuring the perfect texture for material handling or specific ink/adhesive transfer applications.

Rigorous Quality Testing

Every High-Quality Ebonite Roller must pass stringent checks:

- Hardness Testing: Shore D Hardness is measured at multiple points across the face to ensure absolute uniformity and consistency.

- Concentricity and Run-Out Test: The roller is checked for perfect circular rotation. Any deviation (run-out) can cause vibration and pressure inconsistency, which we eliminate by keeping tolerances exceptionally tight.

- Dynamic Balancing: This is a critical test for rollers intended for high-speed operation. The roller is spun on a dynamic balancing machine to ensure mass is distributed perfectly, preventing vibration that leads to component failure.

- Surface Finish Inspection: Surface texture is measured using profilometers to confirm the required Ra value for non-marking or specific grip applications.

By highlighting consistency, safety, and ISO-standard processes, we build the trust that procurement teams rely on when choosing an Ebonite Roller Manufacturer.

Siva Rollers: Engineering Durability. Delivered Locally.

Maintenance Tips for Long Life of Your Ebonite Rollers

Extending the life of your Ebonite Rollers requires simple, consistent preventative maintenance. By following these guidelines, you can maximize the return on your investment in High-Quality Ebonite Roller technology.

- Regular Cleaning and Alignment: Ensure rollers are cleaned regularly using approved, non-aggressive solvents compatible with hard rubber. Crucially, check the roller alignment periodically. Misalignment leads to rapid, uneven wear and premature failure.

- Avoid Chemical Exposure Beyond Limits: While ebonite is resistant, prolonged exposure to concentrated, unapproved chemicals should be avoided. Consult the manufacturer’s chemical resistance chart for compound limitations.

- Periodic Inspection for Wear or Swelling: Visually inspect the surface for cracks, chips, or areas of swelling. Swelling indicates chemical ingress and is a sign that the roller must be replaced or re-ground immediately to prevent machine damage.

- Use Proper Lubricants and Surface Protection: Ensure that all associated bearings and rotating parts are correctly lubricated. Protect the roller surface from physical damage during installation, removal, and storage.

Siva Rollers provides detailed maintenance guidance and schedules for every client, ensuring your team has the expertise needed to keep your rollers running at peak efficiency.

How to Choose the Right Ebonite Roller

If you’re considering an upgrade or replacement, this helpful buyer’s guide from Siva Rollers will ensure you make an informed decision. Choosing the correct roller profile is critical for optimal machine performance.

Consider Roller Size and Diameter

The length and diameter of the roller must perfectly match the specifications of your existing machinery. Ensure your supplier can manufacture custom sizes to avoid modifications to your machine frame. We handle all sizes, from small precision guides to large Industrial Ebonite Rollers.

Understand Surface Hardness Needs

Hardness is measured in Shore D.

- Higher Hardness (90-100 Shore D): Required for applications needing extreme dimensional stability, high load bearing, or where chemical resistance is paramount (e.g., press rollers, steel pickling).

- Lower Hardness (e.g., 75-85 Shore D): Sometimes preferred for intermediate layers or where a slightly softer rubber is layered on an ebonite base for specific grip requirements.

Choose the Right Coating

While Ebonite is the base material, the final surface can be tailored. Do you need a grooved surface for liquid dispersal, or a perfectly smooth, anti-static finish for film handling? Always specify the final surface requirement.

Verify Chemical Resistance for Your Process

Do not assume all hard rubber is the same. If your roller will be exposed to strong acids, strong alkalis, or specific industrial solvents (like MEK or toluene), confirm that the ebonite compound is specifically formulated to resist those agents without swelling or losing its hardness over time.

Prefer Manufacturers Offering Quality Testing and Support

A trustworthy supplier, like Siva Rollers, provides documented quality testing (dynamic balancing reports) and post-sales technical support. This is the difference between purchasing a part and purchasing a performance solution.

Siva Rollers provides free consultation to help you select the perfect Ebonite Roller. Our engineers are ready to analyze your operational conditions and recommend the optimal compound and profile.

Get High-Quality Ebonite Rollers Today

Are you ready to move beyond constant maintenance and poor performance? If you’re looking for durable and cost-effective Ebonite Rollers that maximize your machine’s uptime and output quality, you need the trusted expertise of Siva Rollers.

As the leading Ebonite Roller Manufacturer in India, we are committed to providing tailor-made solutions built for longevity and precision.

Don’t compromise on the backbone of your production line.

Get a Free Consultation and Quote from Siva Rollers Today.

Contact Us Now:

- Call: +91 75070 10009

- Email: info@sivarollers.com

- Inquire: https://www.sivarollers.com/contact-us/

Invest in performance. Invest in Siva Rollers.

FAQs

An Ebonite Roller is a heavy-duty industrial roller coated with vulcanized hard rubber (also called ebonite). After intensive curing with sulfur, the rubber becomes extremely hard, chemically resistant, and dimensionally stable. This makes Ebonite Rollers ideal for high-speed, high-pressure, and chemically harsh environments.

Ebonite Rollers are widely used in printing, packaging, paper & pulp, textile processing, chemical plants, steel pickling lines, film & plastic conversion, and conveyor systems. Wherever smooth movement, pressure control, or chemical resistance is required, ebonite is a top choice.

Ebonite offers superior chemical resistance, higher hardness, excellent dimensional stability, and electrical insulation. Metal rollers vibrate more and corrode, while PU rollers can soften or swell in chemicals. Ebonite gives the consistency and lifespan needed for demanding industrial machinery.

Yes. Siva Rollers manufactures dynamically balanced rollers, ensuring vibration-free performance even at very high RPM. This prevents bearing wear, print defects, and premature machine downtime.

Ebonite typically ranges from 90 to 100 Shore D, depending on application requirements. This hardness ensures the roller does not deform under load and maintains perfect pressure across the machine width.

Yes. Ebonite’s dense cross-linked structure makes it resistant to many aggressive chemicals, including acids and industrial solvents. Siva Rollers also offers customized compounds for specific chemical conditions.

We produce everything from small precision rollers to large industrial press rollers. Every roller is custom-engineered based on diameter, length, shaft type, bearing requirement, and surface finish. Custom grooves, anti-static finishes, and specialized coatings can also be provided.

With correct maintenance, they offer a very long operational life. Ebonite does not soften, swell, or chip easily, and its hardness prevents wear on high-speed lines. Siva Rollers’ strict curing and grinding process further extends lifespan.

Cheap rollers suffer from cracking, swelling, imbalance, poor chemical resistance, uneven thickness, or delamination from the metal core. These issues cause vibration, print errors, wasted material, and frequent shutdowns. Siva Rollers solves these through hardened compounds, CNC grinding, dynamic balancing, and advanced bonding techniques.

Clean regularly with approved solvents, check alignment, avoid exposure beyond chemical limits, and inspect for surface wear. Regrinding can restore surface finish when needed. Siva Rollers provides full maintenance guidelines with every supply.

Yes. We provide hardness testing, dynamic balancing reports, surface finish results, and material certifications upon request. Our process is transparent, traceable, and documented.

Share your machine type, operating speed, chemical exposure, working load, and required surface finish. Our engineers analyze these factors and recommend the ideal compound hardness, coating, and roller size. Free technical consultation is available.

Yes. We supply nationwide and to international buyers. Fast delivery schedules are maintained for both single-piece and bulk orders.

In many cases, yes. The metal core can be reused and recoated with fresh ebonite, reducing cost. Surface regrinding can also restore smooth finish and precision. Our technical team can check and confirm suitability.

Just send your roller size/specifications by phone, email, or inquiry form. Our support team responds within 24 hours with pricing and technical guidance.