Rubber Roller

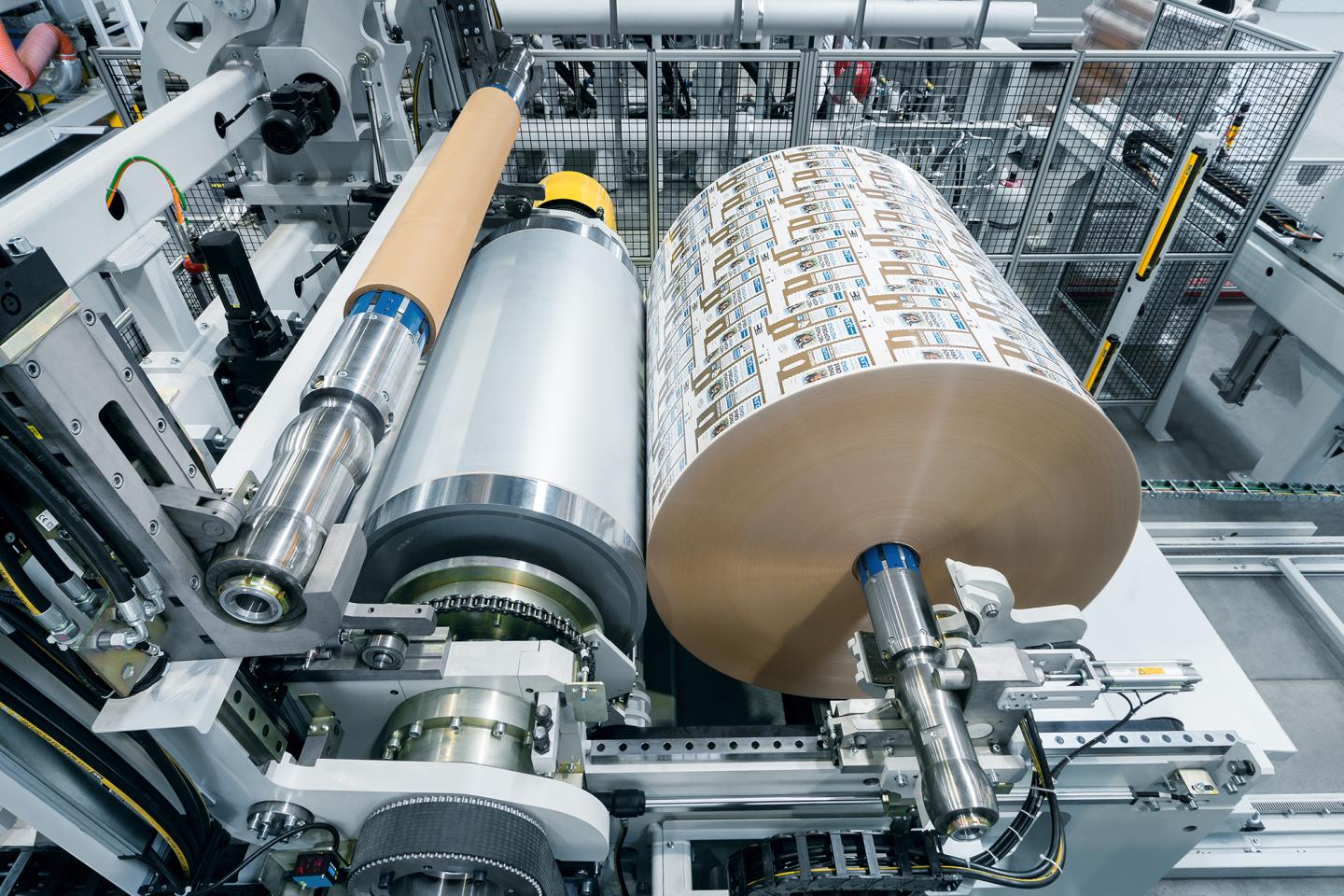

The performance of a rubber roller can directly impact production speed, product quality, and operational uptime. A poorly manufactured or mismatched roller can lead to misalignment, frequent maintenance, surface inconsistencies, and eventually, costly downtime. That’s why choosing the right rubber roller manufacturer India is just as important as selecting the roller type itself.

About Siva Rollers – Your Reliable Rubber Roller Manufacturer in India

Types of Rubber Roller

At Siva Rollers, we manufacture a wide variety of rubber rollers, each tailored to suit specific applications and working environments. Our range includes:

EPDM Rubber Roller

- Excellent resistance to heat, ozone, and weathering

- Suitable for printing, textile, and lamination applications

Nitrile Rubber Roller

- Oil-resistant and durable

- Ideal for packaging, metal, and chemical handling

Silicone Rubber Roller

- Withstands high temperatures

- Commonly used in plastic film, paper, and heat-sealing operations

Neoprene Rubber Roller

- Balanced resistance to chemicals, abrasion, and weather

- Used in wood, paper, and general-purpose applications

Natural Rubber Roller

- High elasticity and grip

- Best suited for textile, printing, and roller coating applications

Each roller is manufactured with precise formulations to ensure optimal performance for your specific industry use.

Applications of Rubber Roller Across Industries

Why Choose a Trusted Rubber Roller Manufacturer?

- Frequent wear and tear requiring constant replacements

- Inconsistent product quality due to surface or hardness mismatch

- Operational delays caused by poor load distribution or material failures

- Higher maintenance costs from misaligned or unbalanced rollers

When you choose Siva Rollers, you’re not just sourcing a product—you’re investing in performance assurance.

As a rubber roller supplier in India trusted by leading industrial players, Siva Rollers offers:

- High-grade elastomers with industry-specific properties

- Precision-balanced rollers for smooth rotation and extended life

- In-house design and tooling for exact-fit customization

- Proven quality assurance processes for zero-defect delivery

That’s the kind of confidence industrial buyers need—especially when their entire production line depends on it.

Siva Rollers Commitment to Quality & Customization

Beyond quality, customization is a core strength. Siva Rollers doesn’t believe in one-size-fits-all. Instead, they collaborate with engineers and procurement teams to design rollers based on:

- Load-bearing requirements

- Chemical exposure

- Surface finish needs

- Speed and temperature parameters

Challenges Faced by Industries Without Quality Rubber Roller

- Uneven material feeding, leading to rejects or reworks

- Downtime from unplanned stoppages due to surface cracks or coating failure

- Product inconsistencies due to pressure imbalance

- Operator fatigue from noisy or vibrating rollers

Partner with Siva Roller – India Trusted Rubber Roller Manufacturer

When it comes to sourcing rubber rollers that truly support your production goals, it pays to go with experience, specialization, and commitment. Siva Roller, based in Ahmedabad,India delivers not just products—but confidence, longevity, and efficiency to your operations.

Reach out today to discuss your roller requirements.

Get in Touch with Siva Rollers

Looking for a trusted rubber roller manufacturer in India?

Whether you need a custom-built roller or want to refurbish your existing one, we’re here to help. We offer fast service, quality products, and expert guidance to keep your operations running efficiently.

FAQs

Rubber rollers are widely used in printing (offset, flexo), textile, paper & pulp, packaging, plastic, and steel processing industries for tasks like feeding, pressing, laminating, and guiding materials with high precision.

Common coatings include Nitrile Rubber (NBR) for general oil and abrasion resistance; EPDM Rubber for excellent heat, chemical, and weather resistance (often used in printing and textile); and specialized compounds like Silicone for high-temperature applications or Polyurethane for superior load-bearing capacity and resilience.

Shore Hardness (measured using the Shore A scale) is a crucial measure of a rubber roller's firmness. Softer rollers (lower Shore A) are typically used for pressure application or material handling that requires high grip, while harder rollers (higher Shore A) are used where dimensional stability and minimal deformation are required, such as in offset printing or calendering.

Inspection frequency depends on operating conditions (speed, temperature, load, chemical exposure). Generally, rollers should be inspected monthly for surface cracks, uneven wear, or hardness changes. Replacement is necessary when the roller is worn beyond acceptable diameter tolerances or when its coating properties (hardness/grip) have degraded significantly.

Precision balancing eliminates vibration, especially at high rotational speeds. Unbalanced rollers cause uneven pressure distribution, leading to material inconsistency (e.g., poor print quality or uneven lamination), increased machine wear, and premature bearing failure. Siva Rollers ensures precision balancing for extended operational life.

A trusted manufacturer like Siva Rollers ensures the use of high-grade elastomers, guarantees dimensional accuracy and perfect Shore Hardness, and provides precision-balanced products. This minimizes costly downtime, improves end-product consistency, and significantly reduces maintenance requirements.

Yes. Siva Rollers specializes in custom-built rubber rollers tailored precisely to customer requirements, factoring in specific load-bearing needs, chemical exposure, speed parameters, and required surface finish for a true purpose-built solution.

Yes, as a leading rubber roller manufacturer in Ahmedabad, Siva Rollers provides comprehensive re-rubberizing services. This cost-effective solution involves stripping the old, worn rubber and applying a new, precision-engineered rubber compound to the existing roller core, returning it to factory specifications.

Siva Rollers, based in Ahmedabad, is a recognized and trusted name in India's industrial landscape, specializing in high-performance rubber coated rollers and industrial rubber rollers for critical sectors like printing, textile, and paper and pulp industries.

High-quality rubber rollers offer several benefits:

- Better grip and control during processing

- Higher resistance to abrasion, heat, and chemicals

- Increased equipment uptime and reduced maintenance

- Improved output consistency and product quality

- Longer operational life

This is why companies across Uttar Pradesh trust Siva Rollers for industrial rubber roller requirements.

Yes, rubber rollers can be repaired or recoated instead of replacing the entire unit. Recoating helps restore the roller surface, correct imbalances, and extend operational life at a lower cost. Siva Rollers provides complete roller refurbishment and recoating services for worn-out rollers.