Rubber Roller Manufacturer in India – Industrial & Custom Rollers | Siva Rollers

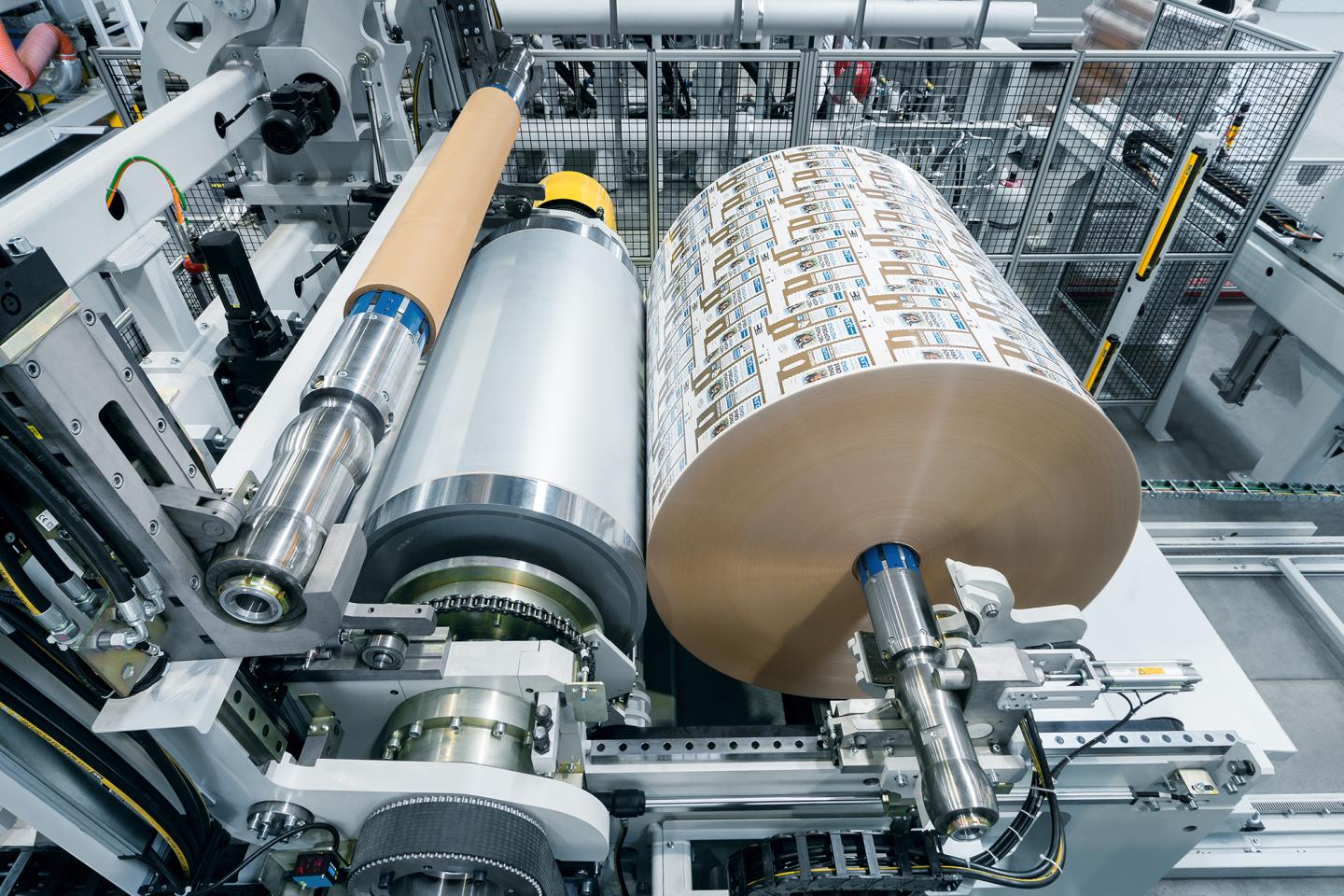

Siva Rollers is a leading rubber roller manufacturer in India, specializing in industrial and custom rubber rollers for printing, packaging, textile, paper, and converting industries. With 10+ years of manufacturing expertise, we deliver precision-engineered rubber rollers designed for long service life, consistent performance, and minimal machine downtime.

Our commitment to superior bonding and dynamic balancing ensures your machines run efficiently with minimal downtime and maximum output. We build long-term relationships based on precision, reliability, and guaranteed performance.

What is a Rubber Roller?

A rubber roller is a precision-engineered cylindrical core (often MS, SS, or Aluminum) coated with a specific elastomeric layer, designed to apply pressure, transfer media (like ink or glue), or control web movement in industrial processes.

The rubber covering is precisely customized for Shore Hardness (A or D), surface finish (glossy, matte, textured), and resistance (oil, heat, solvent) based on the use case. Despite being a crucial component, the rubber roller’s precise role is often overlooked in maintaining consistency, accuracy, and material protection during high-speed processing.

Why Industries Trust Siva Rollers as a Rubber Roller Manufacturer

As an established rubber roller manufacturer in India with four decades of operational experience , Siva Rollers combines unmatched technical expertise with rigorous quality control to deliver superior rollers. We are also a reliable rubber roller exporter to clients across the Middle East, Africa, and Southeast Asia.

- 40+ Years of Rubber Roller Manufacturing Experience

- In-house Rubber Compounding, Grinding & Dynamic Balancing

- ISO-compliant Quality Control Processes

- Serving Printing, Packaging & Textile Industries Pan-India

- Exporting Rubber Rollers to Middle East & Africa

Industries in India that Use Rubber Rollers

This is why rubber roller manufacturer in India is a high-intent search among OEMs, printers, and packaging manufacturers.

This wide usage explains why rubber roller manufacturer in India is a frequent search term among machine builders and factory owners.

Types of Industrial Rubber Rollers We Manufactur

Our expansive product range is designed to meet the technical demands of any web processing line. Each roller is engineered for its specific task and environmental conditions.

| Roller Type (Material) | Key Features | Primary Applications & Industries |

| Nitrile Rubber Rollers (NBR) | Excellent resistance to oils, grease, and solvents. High grip properties. | Packaging, Converting, Anilox roller systems, Printing (Ink transfer), Textile (Fiber transport), Papermaking (Pulp conveying). |

| EPDM Rubber Rollers | Superior resistance to heat, ozone, weather, and water-based inks. | Textile processing, Outdoor applications, High-temperature lines, Flexographic Printing, Tanning. |

| Polyurethane (PU) Rollers | Extreme abrasion and wear resistance. Ideal for heavy loads and sharp materials. | Steel/Metal processing, Heavy-duty Conveyors, Nip rollers, Printing Feeders, Mining, Material Handling. |

| Silicone Rubber Rollers | High thermal stability and non-stick surface properties. | Heat Sealing, Film Lamination, Food Contact/Packaging lines, High-Temperature Printing, Corona Treatment. |

| Ebonite (Hard Rubber) Rollers | Dimensionally stable, high Shore D hardness, and excellent chemical resistance. | Gravure Printing, Flexo applications, Chemical processing, Textile (Washing, Dyeing), Paper/Pulp. |

| Specialty Service Rollers | Anti-static, Chrome-Plated, Teflon-Coated. | Web Handling, Corona Treatment Stations, Precision Metering, Electronics (Anti-static), High-Release Applications (Teflon). |

We also develop Custom Rollers for unique machinery and process requirements, offering specialized coatings and core materials (SS, Aluminium, Carbon Fibre) as needed.

Key Features of Siva Rubber Rollers

Each rubber roller we produce goes through a rigorous quality control process. Here are the standout features that ensure long-term industrial use:

- High Dimensional Accuracy – For proper machine fitting

- Superior Bonding – Rubber-metal bonding for long life

- Uniform Hardness – For smooth and even pressure application

- Dynamic Balancing – Prevents vibration during high-speed operations

- Surface Finish Options – Glossy, matte, textured as required

Common Production Problems & Our Solutions

Choosing the wrong rubber compound or hardness can lead to costly material waste and machine damage. Use our expertise to solve common production problems:

| Production Problem | Siva Rollers Solution | Key Compound/Service |

| Ink Smudging or Ghosting | Precision-ground, uniform-hardness offset printing rollers. | High-Resilience Nitrile (NBR) |

| Film Wrinkling in Lamination | Dynamically balanced rollers with precise surface tension. | EPDM or Silicone Lamination Rollers |

| Roller Wear & Abrasion | Hardened coating for long-term resistance to heavy friction. | High-Toughness Polyurethane (PU) |

| Material Slipping (Poor Grip) | High-friction, specific grooved surface finishes. | Anti-Slip NBR or specialized grip rollers |

Not sure which roller fits? Contact Siva Rollers – your technical partner for industrial rubber rollers in Ahmedabad and across India. Get expert guidance, custom options, and on-time delivery.

Why Rubber Rollers Are in High Demand

Rubber rollers play a silent but crucial role in machines. With automation increasing in industries, demand for durable and process-specific rollers is at an all-time high.

Here’s why rubber rollers are in demand across India:

- Reduced downtime and machine failure

- Higher production throughput

- Material surface protection

- Easy replacement and maintenance

Whether you’re processing plastic film, printing on paper, or laminating flexible materials, you need a roller that won’t fail.

Each type is selected based on process needs and material compatibility.

Export & International Orders

Siva Rollers is not just limited to India. We have expanded our reach globally by supplying rubber rollers to clients in the Middle East, Africa, and Southeast Asia.

Export Capabilities Include:

- International shipping with protective packaging

- Commercial invoicing and documentation

- Export-grade quality control standards

- Remote installation and support assistance

How to Select the Right Rubber Roller?

Problem: Ink smudging in printing

Solution: High-resilience PU printing rollers

Problem: Wrinkles in film during lamination

Solution: EPDM or silicone rubber lamination rollers with balanced hardness

Problem: Material slipping in packaging lines

Solution: Anti-slip NBR or PU grip rollers

Problem: Roller wear in high-speed applications

Solution: Dynamic balanced, chrome-plated or PU-coated rollers

Who Should Buy Rubber Rollers?

Our client base includes a wide range of industries and roles:

- Machine builders and OEMs

- Printing press owners

- Packaging & pouch line manufacturers

- Factory maintenance departments

- Spare part resellers and distributors

- Converting and flexible packaging companies

If your machine handles continuous movement, pressure, or material control—Siva Rollers has the right solution.

Our Quality Assurance (QA) Process

At Siva Rollers, every product is a testament to our commitment to quality. Our strict QA process ensures longevity:

- Raw Material Inspection (Rubber & Metal Core)

- Precision Machining & Grinding

- Advanced Rubber Compounding & Vulcanization

- Superior Bonding (Ensuring rubber stays attached to the core)

- Dynamic Balancing (For vibration-free high-speed use)

- Hardness (Shore) & Dimensional Accuracy Testing

- Final Audit and Certification (Trust Signal)

Find Rubber Roller Manufacturer Near You – Pan-India Service Locations

Siva Rollers supplies and services rubber rollers across every major industrial hub in India.

Choose your location for fast delivery, technical support, and industry-specific roller solutions:

- Rubber Roller Manufacturer in Gujarat

- Rubber Roller Manufacturer in Maharashtra

- Rubber Roller Manufacturer in Tamil Nadu

- Rubber Roller Manufacturer in Uttar Pradesh

- Rubber Roller Manufacturer in West Bengal

- Rubber Roller Manufacturer in Madhya Pradesh

- Rubber Roller Manufacturer in Mumbai

- Rubber Roller Manufacturer in Bangalore

- Rubber Roller Manufacturer in Kolkata

- Rubber Roller Manufacturer in Surat

- Rubber Rollers Manufacturer in Ahmedabad

Contact Your Trusted Rubber Roller Manufacturer in India

Ready to improve your production quality and reduce downtime? Contact Siva Rollers, the leading Rubber Roller Manufacturer in India, for a free consultation, quick quotation, and expert guidance.Based in Ahmedabad, Gujarat, Siva Rollers is a trusted rubber roller manufacturer in India, supplying industrial rubber rollers across Mumbai, Pune, Delhi, Bangalore, Chennai, Kolkata, and other major industrial hubs.

Need help selecting the right rubber roller for your machine? Our engineers are available for technical consultation

Call Us: +91 75070 10009

Email Us: info@sivarollers.com

FAQs

A rubber roller is used in machines to apply pressure, move materials, or control surfaces during manufacturing. It helps with processes like printing, laminating, packaging, and fabric handling. The rubber coating provides grip and protects delicate materials during operation.

Many industries use rubber rollers, especially:

- Printing and offset press units

- Textile machines

- Packaging and converting lines

- Paper and board plants

- Lamination machines

Each of these relies on rollers to maintain speed, accuracy, and product quality.

To make the right rubber roller selection, consider:

- The material you’re processing (paper, plastic, fabric, etc.)

- Operating conditions like temperature, moisture, and chemicals

- Required surface finish (grip, softness, non-stick)

This helps you select the right roller for your process and avoids performance issues.

Siva Rollers offers many types, including:

- EPDM Rubber Rollers (for heat & weather resistance)

- Nitrile Rubber Rollers (oil-resistant)

- Silicone Rubber Rollers (non-stick)

- PU Rollers (durable and abrasion-resistant)

- Ebonite Rubber Rollers (hard finish)

- Printing Rollers for offset presses

- Lamination Rollers

- Hard Chrome Rubber Rollers for added wear resistance

Yes. The right rubber roller can fix:

- Ink smudging or poor print quality

- Uneven pressure on prints or laminates

- Material slipping in machines

These are common printing roller issues, and a quality roller is often the solution.

Typical buyers include:

- Printing press owners

- Factory procurement heads

- Machine builders and OEMs

- Industrial maintenance teams

Rubber rollers are essential in systems handling film, paper, fabric, or laminates.

Yes. Siva Rollers is a rubber roller manufacturer in India and supplies to all major industrial cities. Delivery is available across states with proper packaging and support.

Yes. Global shipping is available. Siva Rollers supports international clients who need rubber roller for industrial machinery. Export orders are handled with proper documentation and transit safety.

Siva Rollers provides:

- Help during installation or replacement

- Suggestions for correct roller usage

- Guidance on selecting spare or backup rollers

This ensures clients get full value from their purchase.

Signs your roller needs replacement:

- Surface cracks or wear

- Uneven pressure during operation

- Slipping or marking issues

Replacing your rubber roller on time helps avoid machine downtime and maintains output quality.

Siva Rollers combines 10+ years of industrial expertise, precision engineering, and in-house rubber compounding to deliver reliable and long-lasting rollers for printing, packaging, textile, and paper industries across India.

Absolutely. We manufacture rollers with custom cores, coatings, hardness, and surface finishes to meet your exact process requirements.