Top Benefits of Using Rubber Coated Rollers in Industrial Applications

In the world of modern manufacturing and production, efficiency, precision, and durability are crucial. To meet these demands, industries are turning to smart engineering solutions that improve performance while reducing costs. One such component that plays a pivotal role across various sectors is the rubber coated roller. From paper and textile industries to steel plants and packaging units, rubber rollers have become indispensable tools for optimizing output and ensuring smooth operations.

What Are Rubber Coated Rollers?

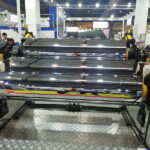

Rubber coated rollers are cylindrical components covered with synthetic or natural rubber. These rollers are used in a variety of machines and serve functions like material conveyance, printing, laminating, pressing, and coating. The rubber layer is tailored in terms of hardness, thickness, and material type to meet specific industrial requirements. Their versatility and customization make them ideal for a wide range of industrial roller applications.

Superior Grip and Traction

One of the most important benefits of rubber coated rollers is their ability to provide excellent grip. Unlike metal rollers, rubber offers natural friction, which helps in better control and movement of materials. In high-speed production lines, this grip minimizes slippage and ensures accurate feed rates.

In the textile and packaging industries, where materials can be thin, slippery, or delicate, maintaining a consistent grip without damaging the product is vital. Rubber rollers provide this functionality seamlessly, reducing material wastage and improving productivity.

Vibration and Shock Absorption

In high-pressure or high-speed industrial settings, machinery can generate intense vibrations and shocks. Metal rollers often transfer these vibrations throughout the system, leading to wear and tear on components. Rubber, on the other hand, naturally absorbs shocks and vibrations.

This cushioning property of rubber rollers extends the life of machines, protects sensitive components, and minimizes maintenance needs. The smoother operation also reduces noise pollution on the factory floor, creating a safer and more comfortable work environment.

Customization for Specific Applications

Rubber coated rollers can be customized to suit specific operational needs. Whether it’s high temperature resistance, chemical exposure, or a requirement for anti-static properties, different types of rubber compounds—like nitrile, EPDM, silicone, or polyurethane—can be used.

This ability to fine-tune the hardness (durometer), texture, and coating thickness allows industries to choose rollers perfectly matched for their application. This level of customization is not possible with traditional metal rollers, making rubber-coated variants a more efficient choice in many scenarios.

Resistance to Corrosion and Chemicals

Metal rollers can corrode over time, especially when exposed to chemicals or moisture. In contrast, rubber rollers offer excellent resistance to harsh environments. They perform well in conditions involving water, acids, solvents, and oils—making them ideal for industries like food processing, printing, and pharmaceuticals.

With industrial rollers exposed to such demanding conditions daily, this resistance is essential for long-term performance and reduced maintenance costs. Rubber-coated rollers maintain their integrity and performance longer, even under continuous exposure to aggressive substances.

Reduced Material Damage

When processing soft, delicate, or polished materials, such as textiles, films, or polished metal sheets, using metal rollers can cause scratches, scuffs, or dents. Rubber rollers, with their softer surface, gently handle these materials without compromising their quality.

This feature is especially important in the printing and paper industries, where surface quality is crucial. The use of rubber rollers helps maintain the integrity of the final product, leading to better quality control and customer satisfaction.

Energy Efficiency

Because of their lighter weight and vibration-dampening characteristics, rubber rollers require less energy to operate in many applications. Machines using rubber rollers often experience less resistance and load during movement, which translates into lower power consumption over time.

In large-scale industrial settings where hundreds of rollers may be operating simultaneously, this energy efficiency contributes significantly to overall cost savings. Less energy use also aligns with global efforts toward sustainable manufacturing.

Enhanced Longevity with Proper Maintenance

When properly manufactured and maintained, rubber coated rollers offer excellent durability. Regular cleaning and occasional recoating can extend their life considerably. In fact, in many industries, instead of replacing the entire roller, companies opt for recoating services, which are cost-effective and environmentally friendly.

Using high-quality rubber and precision bonding techniques also prevents issues like de-lamination or cracking, making these rollers a long-lasting investment.

Versatility Across Multiple Industries

Rubber rollers are used in a wide array of industries due to their adaptable nature. Here are a few examples:

- Textile industry: For calendaring, dyeing, and printing processes.

- Paper industry: For coating, pressing, and conveying.

- Packaging: In lamination, sealing, and slitting machines.

- Steel and metal: Used in coating and polishing lines.

- Printing industry: In offset, flexo, and gravure presses.

This broad usability underlines the value of rubber rollers in day-to-day manufacturing and production.

Cost-Effective and Easy to Replace

Compared to metal rollers, rubber rollers are more affordable to produce and easier to replace or refurbish. Even if the rubber layer wears out, the core (often made of steel or aluminum) can be reused by simply recoating it. This reduces overall operational costs and minimizes machine downtime.

Rubber rollers are also simpler to handle during installation due to their lighter weight and non-slip surface, saving both labor and time in production environments.

Promoting Precision and Product Quality

Rubber rollers enable precise material movement, accurate alignment, and consistent pressure distribution. These factors are critical in industries where small deviations can lead to major defects. For example, in the packaging and converting industries, the alignment of films, foils, or laminates must be exact to avoid production errors.

With the help of rubber rollers, manufacturers can ensure tighter tolerances and better quality assurance in the final output.

Siva Rollers – The Trusted Name in Rubber Coated Rollers

When it comes to sourcing premium quality rubber roller manufacturer in India, Siva Rollers stands out as a reliable and reputed manufacturer. Based in Ahmedabad, India, Siva Rollers specializes in producing a wide range of industrial rollers designed for diverse applications across sectors.

With a commitment to quality, innovation, and customer satisfaction, Siva Rollers has earned the trust of countless clients both in India and globally. Whether you’re looking for custom-built rubber coated rollers or standard sizes, Siva Rollers offers durability, precision, and performance at the highest level.

Final Thoughts

Rubber coated rollers have transformed the way modern industries operate. With benefits ranging from superior grip and vibration absorption to resistance against corrosion and improved energy efficiency, they are a cornerstone of reliable and smooth industrial processes. Their versatility, cost-effectiveness, and durability make them the go-to choice across numerous manufacturing and processing sectors.

If you are looking to invest in high-quality rubber rollers that enhance your machinery’s performance and lifespan, choosing a trusted manufacturer like Siva Rollers is the smart move. With expert craftsmanship and an industry-wide reputation, Siva Rollers is your ideal partner for all industrial roller needs.