Stainless Steel Cladding Roller Manufacturer in India – Buy Direct

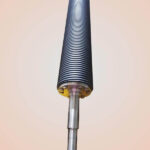

In the dynamic world of industrial manufacturing, precision and durability matter most—especially when it comes to rollers. One such critical component, widely used across various industries, is the Stainless Steel Cladding Roller. Designed to withstand extreme operational stress and offer a high-quality finish, these rollers are indispensable for applications involving metal cladding, laminating, and high-pressure processes.

Across India, industries ranging from steel plants to textile processing units rely on robust, efficient, and corrosion-resistant rollers to enhance their operational capabilities. Among the top-performing components in this segment is the Stainless Steel Roller, which is not only versatile but also engineered for maximum longevity. For businesses looking to buy these rollers directly from trusted manufacturers, India’s manufacturing hubs offer some of the best solutions—especially Ahmedabad, where companies like Siva Rollers have set benchmarks in roller manufacturing.

What is a Stainless Steel Cladding Roller?

A Stainless Steel Cladding Roller is a precision-engineered industrial roller, typically used in machines that require a high-performance surface for pressing, guiding, or transferring material. These rollers are made using stainless steel because of its superior strength, heat resistance, and anti-corrosive properties.

Cladding processes often involve high-temperature and high-pressure operations. The surface of the stainless steel roller ensures consistent contact with materials without degrading under extreme mechanical loads. Whether it’s metal sheet processing, paper mills, or packaging lines, stainless steel cladding rollers maintain uniformity, structural integrity, and surface finish throughout their life cycle.

Applications of Stainless Steel Rollers Across Industries

Stainless Steel Rollers find wide applications across various sectors due to their high durability, hygiene compliance, and precision. These include:

- Metal Cladding and Laminating: Used to laminate layers of stainless steel or other metals onto base materials.

- Textile Industry: Applied in heat setting, dyeing, and finishing machinery where corrosion resistance is essential.

- Printing and Packaging: Serve in high-speed presses and packaging equipment for maintaining consistency and surface quality.

- Food Processing: Used where hygiene and resistance to corrosion are key due to contact with food-grade materials.

- Paper Mills: Applied in calendaring, drying, and surface finishing processes.

These rollers are vital in production environments where continuous operation, minimal downtime, and consistent product output are critical.

Why Stainless Steel Rollers Are Preferred Over Other Materials

Compared to conventional rollers made from aluminum, rubber, or mild steel, Stainless Steel Rollers offer numerous advantages. Stainless steel is naturally resistant to rust and corrosion, which means the roller can operate in environments involving water, chemicals, or humid conditions without degrading. The smooth surface finish of stainless steel allows for easy cleaning, making it ideal for food, pharma, and cleanroom applications.

In cladding applications, the toughness of stainless steel ensures minimal deformation, even under high pressure. This directly translates into greater operational life, reduced maintenance needs, and better return on investment. It also supports higher loads and can be customized with a polished or brushed finish depending on the requirement.

How to Select the Right Stainless Steel Cladding Roller

Selecting the right roller depends on your specific industry needs, machine compatibility, and processing conditions. A few crucial factors include:

- Roller Diameter and Length: Must be in accordance with the machine setup.

- Surface Finish: Polished, brushed, or coated as per material interaction.

- Load Capacity: Should withstand operational stress without deformation.

- Material Grade: Different grades of stainless steel (304, 316, etc.) offer varying corrosion resistance.

- Balancing and Concentricity: Ensures vibration-free operation, which is critical in high-speed systems.

By consulting with experienced manufacturers, you can get a custom-engineered roller tailored to your specifications.

Siva Rollers – Best Stainless Steel Cladding Roller Manufacturer in Ahmedabad, India

When it comes to sourcing high-quality Stainless Steel Rollers in India, Siva Rollers stands out as a pioneer in the field. Based in Ahmedabad, Siva Rollers has over a decade of experience delivering precision rollers to leading manufacturers across the country.

Their rollers are manufactured using high-grade stainless steel, meticulously machined for superior tolerance, and tested for performance under extreme conditions. What sets Siva Rollers apart is their ability to offer custom-designed solutions that meet client-specific demands while ensuring quick delivery and competitive pricing.

Whether you’re operating in the paper, metal, textile, or packaging industry, Siva Rollers delivers unmatched quality with technical support, ensuring a seamless buying experience. Buying direct from the manufacturer like Siva Rollers not only saves costs but also ensures better post-sale service and customization flexibility.

Buy Direct from Manufacturer – Why It Makes a Difference

Purchasing a Stainless Steel Cladding Roller directly from the manufacturer brings multiple benefits. Firstly, it eliminates the cost layers added by middlemen or distributors, allowing you to get better quality at a lower price. Secondly, manufacturers can tailor the rollers to meet exact operational requirements, including dimensions, surface treatments, and load tolerances.

Additionally, direct communication allows better understanding of the roller’s lifespan, installation process, and required maintenance. You can also build long-term supplier relationships for repeat purchases, spares, and technical support.

Buying direct is also a smart choice for businesses looking to scale, as it ensures consistent quality and the ability to upgrade or modify equipment components as needed.

Stainless Steel Roller – Pricing Factors

While it may be tempting to seek low-cost options, the Stainless Steel Roller price depends on several factors:

- Material Grade: Higher-grade stainless steel increases the cost but improves performance.

- Size and Dimensions: Larger, thicker, or longer rollers will naturally cost more.

- Surface Finish and Coating: Specialty finishes and coatings add to the price.

- Customization: Tailored designs involve more engineering and machining efforts.

- Volume: Bulk orders can lower the cost per unit significantly.

Rather than just looking at the price, focus on value for money, considering the roller’s performance, lifespan, and service support from the manufacturer.

Quality Testing and Performance Assurance

Reputable manufacturers like Siva Rollers subject each Stainless Steel Cladding Roller to rigorous quality control. These tests include:

- Dynamic Balancing Tests

- Hardness and Surface Roughness Testing

- Dimensional Inspection

- Runout and Concentricity Checks

- Corrosion Resistance Verification

These quality checks ensure every roller meets international standards, minimizing the risk of failure during operation.

Sustainability and Reusability of Stainless Steel Rollers

Unlike coated or composite rollers, Stainless Steel Rollers are more sustainable as they are recyclable and reusable. Damaged surfaces can often be repaired or resurfaced, extending the roller’s usability without needing a full replacement.

Siva Rollers also supports regrinding, refurbishing, and re-coating services, making them a more eco-friendly choice for industries looking to reduce their environmental footprint while optimizing costs.

Why Indian Manufacturers Lead in Stainless Steel Roller Innovation

India’s manufacturing landscape has evolved drastically, with cities like Ahmedabad becoming a hub for engineering excellence. Indian manufacturers now offer world-class quality at competitive prices. Using advanced CNC technology, 3D CAD design systems, and skilled craftsmanship, companies like Siva Rollers match global standards in performance and reliability.

Moreover, the “Make in India” initiative further empowers local manufacturers to improve infrastructure, quality control, and R&D, benefitting industries across sectors.

Final Thoughts – Choose Precision, Choose Trust

A Stainless Steel Cladding Roller is more than just a machine part—it’s a performance tool that affects your entire production quality. Whether you are upgrading old equipment or building new machinery, investing in high-quality stainless steel rollers ensures smoother operations, reduced downtime, and higher efficiency.

Choosing the right manufacturer is crucial. By opting to buy direct from trusted Indian manufacturers like Siva Rollers, you gain access to technical expertise, customized designs, and ongoing support. Siva Rollers remains a trusted name in the industry, offering precision, performance, and perfection with every product they deliver.

FAQs

A Stainless Steel Cladding Roller is a precision industrial roller used for metal cladding, laminating, and pressing applications. Made from corrosion-resistant stainless steel, it ensures high durability and performance in demanding industrial environments.

These rollers are widely used in metal processing, textile, food, packaging, printing, and paper industries due to their resistance to wear, corrosion, and high heat.

Stainless steel offers high strength, excellent corrosion resistance, and a smooth surface finish, making it ideal for heavy-duty, high-speed, and cleanroom applications.

Grades like SS304 and SS316 are commonly used depending on the application’s chemical exposure, temperature, and mechanical load.

Yes, manufacturers like Siva Rollers offer fully customized rollers based on size, load requirements, surface finish, and operational conditions.

Yes, Chrome Coated Rollers can often be refurbished. The process usually involves stripping the old chrome, re-machining the surface, and reapplying a fresh chrome layer. This extends the roller’s life and reduces replacement costs, making it a cost-effective maintenance strategy.

Key price factors include the grade of stainless steel, roller size, design complexity, surface finish, and order quantity.

Regular cleaning, periodic inspections for wear or damage, and proper storage in dry, clean environments ensure long life and optimal performance.

Siva Rollers provides high-quality, custom-engineered stainless steel rollers, backed by technical support, precision machining, and strict quality testing.

Yes, direct purchase ensures better pricing, custom options, after-sales support, and consistent quality control.

With proper use and maintenance, a stainless steel roller can last several years, even in high-pressure or corrosive environments.