Buy PU Coated Rollers Direct from Manufacturer – Contact Us

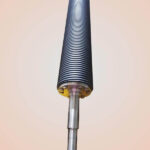

In industries where precision, durability, and performance are crucial, choosing the right rollers can make a significant impact on operational efficiency. PU Coated Rollers—also known as polyurethane coated rollers—have become the preferred choice across diverse sectors due to their superior performance, wear resistance, and long service life. Purchasing directly from a trusted manufacturer ensures not only the best pricing but also the highest quality, tailored specifications, and prompt support.

For businesses looking to invest in industrial rollers that can withstand challenging environments, buying PU coated rollers direct from the manufacturer is the smartest and most cost-effective approach.

Why PU Coated Rollers Are Vital for Modern Industries

Polyurethane is one of the most resilient and versatile coating materials available today. When applied to rollers, it creates a protective, impact-resistant layer that offers excellent performance under heavy loads and demanding conditions. PU-coated surfaces combine flexibility and hardness, making them perfect for industries such as printing, packaging, textiles, paper, laminating, steel processing, and food manufacturing.

Unlike rubber or metal-only rollers, polyurethane-coated rollers deliver superior resistance to abrasion, chemicals, solvents, and wear. They also absorb shock and vibration effectively, which protects delicate materials during processing and reduces machine downtime caused by roller failure. This combination of features makes them an ideal choice for operations seeking longevity and consistent performance.

Benefits of Buying PU Coated Rollers Direct from the Manufacturer

When you source PU coated rollers directly from a manufacturer, you eliminate the extra costs added by middlemen and dealers. More importantly, you gain access to custom-built rollers designed to your specific load, size, and performance requirements. Manufacturers understand the demands of your industry and can engineer rollers that deliver exact results.

Buying direct ensures:

- Better Quality Control – You receive rollers built with precision, tested for hardness, durability, and uniform coating thickness.

- Cost Efficiency – No distributor markups mean more competitive pricing.

- Customization – Sizes, hardness, colors, and coatings can be tailored to match your operational needs.

- Technical Support – Direct manufacturers offer guidance on installation, maintenance, and lifespan optimization.

Applications of Polyurethane Coated Rollers in Industry

PU coated rollers are highly adaptable, serving critical roles across multiple sectors. Their common applications include:

- Printing and Packaging – For smooth, consistent ink transfer and film handling without scratching or marking materials.

- Steel and Metal Processing – Providing wear-resistant handling of heavy sheets and coils.

- Textile and Fabric Manufacturing – Ensuring gentle yet firm tension control without damaging delicate fabrics.

- Lamination and Paper Industries – Offering precision for feeding, laminating, and cutting operations.

- Food and Beverage Production – Non-toxic coatings suitable for hygienic material handling.

Because polyurethane is available in various durometers (hardness levels), these rollers can be optimized for soft, flexible contact or firm, impact-resistant applications.

Why Choose Polyurethane Coated Rollers Over Other Materials?

While rubber and metal rollers have been industry standards for years, polyurethane-coated rollers offer several advantages that make them the preferred option:

- Superior Abrasion Resistance – PU coatings last longer under heavy friction and pressure.

- Chemical and Oil Resistance – Ideal for industries exposed to harsh cleaning agents or lubricants.

- Lightweight yet Strong – Easier to handle without compromising strength and load capacity.

- Non-Marking and Smooth Operation – Prevents damage to delicate films, sheets, or printed materials.

- Extended Lifespan – Reduces replacement frequency and overall operating costs.

These properties reduce maintenance downtime and improve overall productivity, giving industries a competitive edge.

Why Siva Rollers is the Best PU Coated Rollers Manufacturer in India

When it comes to sourcing reliable and precision-engineered PU coated rollers, partnering with an experienced manufacturer is key. Siva Rollers, a trusted name in industrial roller manufacturing, is renowned as the best PU coated rollers manufacturer in India.

Siva Rollers offers:

- High-Quality Polyurethane Coatings – Designed for maximum durability and smooth operation.

- Tailored Solutions – Custom sizes, hardness levels, and coatings to suit any industry.

- Advanced Manufacturing Facilities – Using cutting-edge technology for accurate roller production.

- Competitive Pricing – Direct-from-manufacturer rates for cost-effective procurement.

- Nationwide Delivery – Serving industries across India with prompt support and service.

With a track record of serving industries like printing, steel, paper, textiles, and food processing, Siva Rollers is a trusted partner for businesses that demand high-quality industrial rollers.

How to Select the Right PU Coated Roller for Your Operation

Choosing the right polyurethane coated roller depends on several operational factors. These include load requirements, speed, environmental conditions, and the type of material being processed. When buying direct from a manufacturer, these specifications can be discussed in detail to ensure the roller meets your exact needs.

Manufacturers like Siva Rollers consider:

- Roller diameter and length for load distribution.

- Hardness (measured in Shore A) for the right balance of grip and durability.

- Coating thickness for extended lifespan.

- Temperature and chemical resistance based on operating environments.

By customizing these aspects, businesses can maximize performance and avoid premature roller wear or equipment failure.

The Cost Advantage of Buying PU Coated Rollers Direct

One of the most compelling reasons to purchase directly from a PU coated roller manufacturer is cost efficiency. Without third-party markups, businesses save significantly, especially when buying in bulk or requiring specialized sizes. Direct sourcing also ensures transparency on material quality and coating specifications, so you know exactly what you’re paying for.

Moreover, manufacturers often provide maintenance advice and after-sales service, which extends the life of the rollers and maximizes your return on investment.

Enhance Your Operations with PU Coated Rollers

Industries today face increasing pressure to improve efficiency, reduce costs, and maintain product quality. PU coated rollers offer the performance, durability, and customization needed to achieve these goals. By buying directly from trusted manufacturers like Siva Rollers, companies not only secure high-quality rollers but also gain a reliable partner to support their production needs.

Invest in polyurethane-coated industrial rollers that deliver long-lasting results and drive operational success. Reach out to Siva Rollers today to discuss your specifications and get the best value for your industrial roller requirements.

FAQs

PU coated rollers, also called polyurethane coated rollers, are used for printing, packaging, textiles, lamination, and heavy-duty material handling due to their durability and smooth operation.

Polyurethane coated rollers last longer, resist abrasion and chemicals better, and provide non-marking, smooth handling, making them ideal for high-performance industries.

With proper maintenance, PU coated rollers can last significantly longer than rubber rollers, often 2–3 times longer, depending on usage and environmental factors.

Yes. Buying PU coated rollers directly from a manufacturer ensures cost savings, customization, and better quality control compared to buying through dealers.

Printing, packaging, textiles, paper, steel processing, and food manufacturing industries rely on PU coated rollers for their superior strength and performance.

Consider the roller diameter, length, hardness (Shore A), coating thickness, load requirements, and operating environment when selecting a polyurethane coated roller.

Yes. Polyurethane coatings are highly resistant to oils, solvents, and chemicals, making them suitable for harsh industrial environments.

Siva Rollers is a leading manufacturer in India, offering high-quality polyurethane coated rollers customized for diverse industrial applications.

They reduce downtime by offering longer service life, consistent performance, and less maintenance, boosting overall production output.