Industrial Rubber Coated Rollers for Printing & Packaging – Buy Direct from Manufacturer

In the fast-paced industries of printing and packaging, efficiency, precision, and durability are the cornerstones of success. At the heart of these operations lies one essential component – industrial rubber coated rollers. These rollers ensure seamless material handling, consistent pressure application, and smooth surface contact, making them vital for industries like printing, laminating, packaging, textiles, steel, and converting. Businesses across India increasingly prefer to source directly from a Rubber Roller Manufacturer in India to ensure cost efficiency, quality assurance, and long-lasting performance.

This guide explores why rubber coated rollers are indispensable for printing and packaging operations, what benefits they offer, and why buying directly from a roller manufacturer like Siva Rollers can help you achieve superior results and better ROI.

Why Rubber Coated Rollers Are Crucial in Printing & Packaging

Rubber coated rollers play a vital role in ensuring that substrates – whether paper, film, foil, or fabric – move smoothly and evenly through printing and packaging machines. They provide controlled friction, precise tension, and even pressure, which are essential for consistent printing, accurate lamination, and flawless packaging output.

The rubber coating on these rollers helps absorb shock, reduces slippage, and improves grip on delicate or high-speed materials. This ensures that operations like ink transfer, lamination adhesion, and sealing remain accurate even at high production speeds. Without the correct industrial roller, productivity suffers, and material wastage increases, which can significantly impact profitability.

The Importance of Choosing the Right Rubber Roller in India

For businesses operating in India, sourcing the right rubber roller in India is crucial because local manufacturing ensures faster delivery, easier customization, and cost savings compared to imports. A reliable roller manufacturer can customize the hardness (durometer), rubber compound, and dimensions based on specific printing or packaging requirements, ensuring the rollers meet operational standards.

Local rubber roller manufacturers in India also offer after-sales services such as re-rubberizing, recoating, and balancing, which extend the roller’s lifespan and reduce downtime. When you purchase from a trusted source like Siva Rollers, you gain access to expert engineering, precision manufacturing, and consistent quality – all while supporting a domestic supply chain.

Benefits of Industrial Rubber Coated Rollers in Printing & Packaging

High-quality rubber coated rollers provide multiple advantages that directly enhance the efficiency of printing and packaging lines. Their smooth operation ensures consistent ink coverage in printing, bubble-free lamination, and uniform sealing in packaging. The rubber coating absorbs vibrations, prevents damage to delicate materials, and withstands high-speed operations without deformation.

Another benefit is the customization of rubber compounds. Depending on the application, manufacturers can design rollers using natural rubber, nitrile, EPDM, silicone, or polyurethane coatings. Each compound is engineered to handle different chemical, thermal, and mechanical demands, allowing businesses to use the rollers in diverse environments – from solvent-based printing to food-grade packaging lines.

Most importantly, these rollers reduce maintenance costs. Their durable coating resists wear, chemical damage, and environmental degradation, which means they last longer than uncoated or low-quality rollers, providing businesses with a better return on investment.

How Rubber Coated Rollers Enhance Printing Quality

In the printing sector, precision is everything. Uneven pressure or improper material feed can cause misalignments, blurred prints, or uneven ink distribution. Industrial rubber coated rollers eliminate these issues by maintaining uniform tension and contact pressure. This ensures accurate ink transfer, sharp image resolution, and reduced wastage during high-volume print runs.

Rubber coatings also help protect delicate substrates like thin films or specialty papers by preventing scratches or surface damage. By using the right roller hardness and coating, printers can achieve higher speeds and superior quality without compromising output.

Role of Rubber Coated Rollers in Packaging Efficiency

The packaging industry relies on industrial rollers for tasks like laminating, embossing, coating, and sealing. These rollers must operate smoothly across various materials, including plastic films, foils, and laminates. Rubber coated rollers ensure uniform pressure application, preventing defects like bubbles, wrinkles, or misaligned seals, which can ruin packaging aesthetics and functionality.

High-quality rollers can withstand the heat and pressure of lamination or sealing processes without cracking or degrading. They also reduce friction, minimizing static build-up and material tears, which is critical for high-speed automated packaging lines.

Why Buy Direct from a Rubber Roller Manufacturer in India?

Purchasing directly from a rubber roller manufacturer in India offers significant advantages over distributors or third-party vendors. Manufacturers can deliver custom-engineered rollers tailored to your specific machinery and operational needs. They also provide competitive pricing by eliminating middlemen, ensuring you get the best value for your investment.

Direct sourcing also means better quality control, as the manufacturer oversees the entire production process, from selecting rubber compounds to precision machining and finishing. If your operations demand fast replacements or regular maintenance, partnering with a manufacturer ensures timely support and reduced downtime.

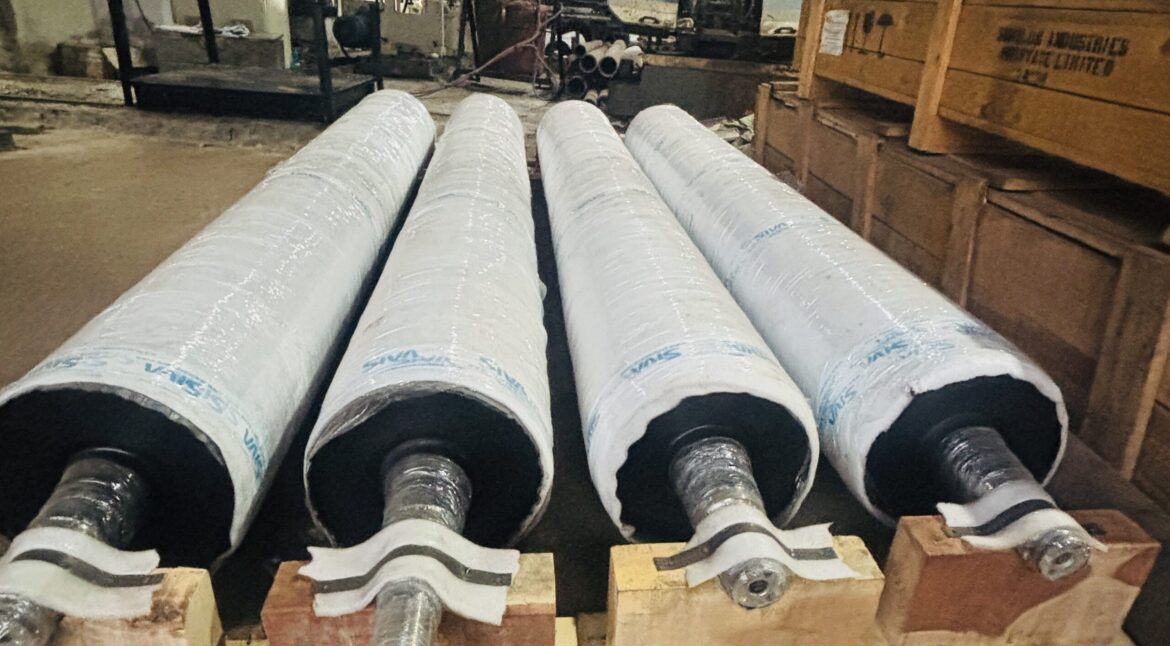

Siva Rollers – The Best Rubber Coated Roller Manufacturer in India

When it comes to reliability, precision, and quality, Siva Rollers stands as the leading name in India’s industrial roller manufacturing sector. Known for engineering rubber coated rollers that meet international standards, Siva Rollers serves industries like printing, packaging, textiles, and steel with unmatched expertise.

With state-of-the-art manufacturing facilities, precision balancing, and advanced rubber compounding, Siva Rollers ensures every roller delivers superior performance and extended service life. Businesses prefer Siva Rollers not only for their quality products but also for their responsive customer service, cost-effective solutions, and ability to deliver both standard and custom rollers for any industrial application.

Customization Options for Industrial Rubber Coated Rollers

One of the biggest reasons industries choose a specialized roller manufacturer is the ability to customize. At Siva Rollers, every roller is engineered to meet the exact specifications of your production line. Options include varying roller diameters, face lengths, rubber hardness levels, and compound selection to handle specific chemicals, temperatures, or substrates.

Custom coatings can be designed for food-grade packaging, solvent-based inks, or heavy-duty steel processing, ensuring optimal performance and compliance with industry standards. Precision dynamic balancing is also applied to minimize vibrations and improve the overall stability of high-speed machines.

Ensuring Long Lifespan with Proper Maintenance

While rubber coated rollers are built for durability, their lifespan depends on proper care. Regular cleaning, inspection for wear, and timely re-rubberizing can prevent unexpected breakdowns and costly downtime. Trusted manufacturers like Siva Rollers offer refurbishment and recoating services, helping businesses maximize the value of their investment and maintain consistent performance over time.

The Future of Industrial Rollers in Printing & Packaging

As printing and packaging industries evolve toward automation, speed, and precision, the demand for high-performance industrial rollers will continue to grow. Rollers with advanced coatings, anti-static properties, and higher chemical resistance will become standard to meet the needs of modern manufacturing lines.

By partnering with a reliable rubber roller manufacturer in India, businesses can stay ahead of these trends and ensure their machinery runs at peak efficiency.

Choose Siva Rollers for Superior Rubber Coated Roller

Whether you operate a printing press, lamination unit, or packaging plant, your production efficiency depends on the quality of your rubber coated rollers. Investing in precision-engineered rollers from a trusted roller manufacturer like Siva Rollers not only improves your product quality but also reduces costs associated with maintenance and downtime.

With a reputation as the best rubber coated roller manufacturer in India, Siva Rollers delivers unmatched quality, custom solutions, and dependable service – making them the preferred choice for businesses across India.

FAQs

Rubber coated rollers ensure smooth material handling, even pressure, and precise ink or adhesive transfer in printing and packaging machines, improving quality and reducing wastage.

Buying from a rubber roller manufacturer in India offers cost savings, faster delivery, and customization options for different industries, along with after-sales support.

They provide uniform tension, accurate ink transfer, and smooth material movement, preventing smudges, uneven coverage, and misalignment in high-speed printing.

Common compounds include natural rubber, nitrile, EPDM, silicone, and polyurethane. Each is chosen based on the application’s heat, chemical, and mechanical requirements.

With proper care and maintenance, high-quality industrial rubber coated rollers can last several years. Recoating or refurbishing can further extend their lifespan.

Yes, manufacturers like Siva Rollers offer custom diameters, lengths, rubber hardness, and coatings to meet the exact needs of your printing or packaging line.

They are widely used in printing, packaging, textiles, steel, converting, paper, and lamination industries due to their durability and performance.

Regular cleaning, avoiding chemical damage, and timely recoating by a trusted roller manufacturer help maintain performance and reduce breakdowns.

Yes, depending on the rubber compound used. Silicone and nitrile rollers, for example, can withstand high temperatures and solvent exposure.

Siva Rollers is one of the most trusted names, offering premium-quality, customizable rollers with superior durability and performance for printing and packaging industries.

Before ordering, verify:

- Exact dimensions and technical specifications

- Material and coating type based on application

- Manufacturer’s credentials and quality certifications

- Customization options and lead time

- Warranty or service support

It’s advisable to connect with a reputed supplier like Siva Rollers, who offer expert consultation and 100% inspection before dispatch.