What Is a PU Coated Roller? Complete Guide for Industrial Use

In today’s fast-paced industrial environment, the need for high-performance components is greater than ever. Among the many elements that ensure smooth production processes, PU Coated Rollers have gained massive attention for their versatility, durability, and performance.

Whether it’s paper, textile, printing, packaging, steel, or material handling industries, PU Rollers are the unseen force driving efficiency and precision. This comprehensive guide explains what PU coated rollers are, their key uses, benefits, material properties, and why industries across India are rapidly switching to them.

What Are PU Coated Rollers?

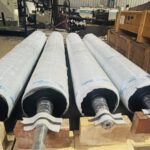

PU (Polyurethane) Coated Rollers are industrial rollers that feature a metal or composite core covered with a layer of polyurethane. This coating acts as a resilient, high-friction surface that provides better load-bearing capacity, wear resistance, and chemical stability.

Unlike rubber or plastic coatings, polyurethane delivers superior abrasion resistance, cut resistance, and performance under pressure, making PU rollers ideal for high-speed, heavy-duty industrial applications.

PU rollers are available in different hardness levels (measured in Shore A/D), thicknesses, and surface finishes depending on the application—ranging from soft-touch conveyor rollers to high-pressure squeezing rollers.

Why PU Rollers Are Preferred in Modern Industry

The shift from conventional rubber rollers to PU coated ones is a result of the superior mechanical properties and adaptability of polyurethane. Here’s why PU rollers have become a top choice for manufacturers:

- Exceptional Abrasion Resistance

PU coating handles intense friction without wearing out quickly. This is especially important in high-speed conveyor lines or printing machines where the rollers run continuously. - High Load Capacity and Resilience

PU coated rollers can sustain high loads and still maintain elasticity, making them ideal for pressure rollers, nip rollers, and squeezing applications in industries like textile and steel. - Oil, Solvent & Chemical Resistance

Industrial environments often involve oils, inks, and cleaning chemicals. Polyurethane naturally resists many of these substances, unlike conventional rubber which deteriorates faster. - Non-Marking & Gentle Contact

PU Rollers are non-marking, which makes them perfect for delicate surfaces like glass, aluminum sheets, or laminates. Their soft yet durable nature ensures the material being handled remains damage-free.

Industries That Rely on PU Coated Rollers

PU coated rollers have penetrated a vast number of industries in India and globally due to their reliability and performance. Let’s look at where and how they are commonly used:

- Printing Industry

In offset and flexographic printing, PU coated printing rollers are used for ink transfer, pressure application, and smooth paper feeding. Their wear resistance allows high-quality print output without downtime. - Packaging & Converting

PU Rollers play a vital role in laminators, slitters, and bag-making machines, offering smooth web handling and minimal static. The PU coating resists ink, glue, and film adhesion, making cleaning easier. - Textile Industry

In textile manufacturing, PU rollers are used for fabric guiding, tensioning, and calendaring. Their surface smoothness prevents fabric damage and ensures consistent output. - Steel & Metal Processing

Heavy-duty industrial rollers with polyurethane coatings are used for sheet guiding, coil processing, and deflection handling due to their toughness and shock absorption capacity. - Material Handling Systems

In conveyor systems across warehouses and assembly lines, PU rollers offer quiet operation, grip, and long service life. They support both light and heavy loads efficiently.

Benefits of PU Coated Rollers Over Traditional Rollers

What truly sets PU rollers apart is the balance between flexibility and durability. Here’s a deep dive into the core benefits:

- Longer Service Life

PU coated rollers can last up to 4–5 times longer than rubber rollers under the same working conditions. - Custom Hardness & Finish

The polyurethane layer can be molded to various Shore hardness levels. Whether you need soft grip or rigid structure, PU can be customized to your needs. - Cost Efficiency Over Time

While initial investment in PU rollers may be slightly higher, the extended life cycle, reduced maintenance, and minimal downtime make them a more cost-effective choice in the long run. - Temperature Resistance

PU coatings can withstand a wide range of temperatures, from cold storage conveyors to hot material lines, without degrading in performance. - Noise Reduction

Polyurethane dampens vibration and noise much better than metal or hard plastic rollers, improving the work environment.

Choosing the Right PU Coated Roller

When selecting PU rollers for your industrial setup, it’s essential to consider the following factors:

- Load and Speed Requirements

Higher loads and speeds demand tougher PU formulations and precision balance. - Environmental Exposure

If your process involves oils, inks, solvents, or extreme temperatures, choose a chemically resistant PU grade. - Roller Surface Design

Grooved, crowned, or flat surfaces may be needed depending on the contact and material type. - Core Material

Roller cores are typically made from steel, aluminum, or composite materials. Core strength should match the mechanical demands of the application.

Siva Rollers – Best PU Coated Roller Manufacturer in India

If you’re looking for top-quality PU Coated Rollers that meet industrial standards and last longer under heavy-duty operations, Siva Rollers is the name trusted across India.

Siva Rollers specializes in manufacturing customized PU Rollers, delivering unmatched precision, performance, and value. From design consultation to bulk manufacturing, their expertise ensures you get rollers that suit your machinery and process exactly.

With decades of experience and cutting-edge production facilities, Siva Rollers is the leading PU Coated Roller Manufacturer in India, serving industries such as printing, packaging, textile, steel, and logistics.

PU Coated Rollers: Future-Proofing Industrial Efficiency

As industries modernize, the demand for components that can keep up with speed, accuracy, and durability is on the rise. PU coated rollers provide that perfect edge.

Whether you’re upgrading an old system, designing a new production line, or seeking replacements that last longer, PU rollers are a smart investment for long-term gains.

With superior performance across diverse applications, it’s clear that PU Coated Rollers are the future of industrial motion and material handling.

Final Thoughts

Investing in PU Rollers means choosing durability, precision, and efficiency. As competition grows and machines are pushed harder, using components that can endure the load without compromising performance is essential.

Partner with experts like Siva Rollers—India’s trusted source for industrial rollers—to ensure you get value-driven solutions customized to your operational needs.

Want your production to run smoother, longer, and with fewer breakdowns?

Choose PU Coated Rollers. Choose Siva Rollers.

FAQs

A PU Coated Roller is an industrial roller made with a metal or composite core covered in polyurethane (PU). These rollers are widely used in industries due to their excellent wear resistance, load-bearing capacity, and chemical resistance. PU Rollers outperform traditional rubber rollers in both performance and lifespan.

PU Rollers are used in a wide range of industries including printing, packaging, textile, steel processing, and conveyor systems. They are ideal for applications involving high-speed rotation, heavy loads, ink transfer, fabric tensioning, web guiding, and material movement.

PU Coated Rollers offer numerous advantages such as:

- High abrasion and wear resistance

- Resistance to oils, chemicals, and solvents

- Long service life

- Customizable hardness and surface finishes

- Quiet and smooth operation

These qualities make them the preferred industrial rollers for harsh environments.

While both are used in industrial applications, PU Rollers last significantly longer and offer better resistance to abrasion, oils, and chemicals. They also support heavier loads and maintain performance at high speeds, unlike rubber rollers which degrade faster in tough environments.

Yes. PU Coated Rollers can be customized in terms of:

- Shore hardness

- Coating thickness

- Surface texture (grooved, flat, crowned)

- Core material (steel, aluminum, composite)

Custom PU rollers ensure better performance and precision in specific machinery setups.

Industries that heavily rely on PU Coated Rollers include:

- Printing and converting

- Flexible packaging

- Textile and non-woven fabric

- Steel and aluminum sheet processing

- Conveyor and automation systems

You can buy top-grade PU Coated Rollers in India from Siva Rollers – a leading manufacturer known for precision engineering and custom roller solutions. They offer high-performance PU Rollers tailored to industrial requirements across printing, packaging, textile, and more.

The lifespan of PU rollers depends on their application, load, and operating environment. However, under standard conditions, PU coated rollers can last 3–5 times longer than traditional rubber rollers, making them more cost-effective in the long run.

Yes. Polyurethane (PU) is highly resistant to a wide range of chemicals including oils, solvents, inks, and cleaning agents. This makes PU rollers ideal for environments where exposure to such substances is common.

They reduce downtime by offering longer service life, consistent performance, and less maintenance, boosting overall production output.