Premium Quality Ebonite Scroll Rollers for Industrial Applications

In the fast-paced industrial world, efficiency, precision, and durability are key factors that drive productivity. Among the many components that keep industrial machinery running smoothly, Ebonite Scroll Rollers stand out as a vital element in ensuring flawless operations. Known for their robustness, chemical resistance, and long-lasting performance, these rollers are a preferred choice in sectors such as printing, textile, packaging, paper, and many more.

Whether you are looking to upgrade your current machinery or install new equipment, investing in premium quality Ebonite Scroll Rollers can significantly enhance your production efficiency and product quality. In this blog, we will explore what makes Ebonite Scroll Rollers indispensable for industrial applications, their advantages, and why choosing a trusted manufacturer like Siva Rollers Best Ebonite Scroll Rollers Manufacturer in India can make all the difference.

Understanding Ebonite Scroll Rollers

Ebonite, also known as hard rubber, is a material made by vulcanizing natural rubber with a high percentage of sulfur. This process creates a rigid, highly durable surface that is resistant to wear, chemicals, and moisture.

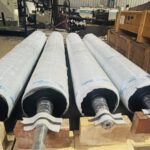

Ebonite Scroll Rollers are cylindrical components with spiral (scroll) patterns on their surface, designed to guide, align, or transport materials through a machine with precision. The scroll pattern prevents slippage, improves grip, and ensures even material distribution, making them an essential choice for industries that require consistent, controlled movement.

Key Advantages of Ebonite Scroll Rollers in Industrial Applications

The reason Ebonite Scroll Rollers have become an industry favorite is due to their unmatched performance benefits:

- Exceptional Durability

Ebonite’s hard surface resists wear and tear even in high-friction, high-pressure environments. This means less downtime and fewer replacements, ultimately reducing maintenance costs. - Chemical and Moisture Resistance

Industries dealing with chemicals, solvents, inks, or water-based products need rollers that can withstand harsh environments. Ebonite Scroll Rollers offer superior resistance, ensuring consistent performance. - Precision Material Handling

The scroll design plays a crucial role in ensuring proper alignment and smooth material movement. This precision minimizes wastage and improves product quality. - Cost-Effectiveness Over Time

Although premium-quality rollers may seem like a bigger investment initially, their extended lifespan and reduced maintenance make them far more economical in the long run. - Versatility Across Industries

From paper manufacturing to packaging and textile production, these rollers adapt to multiple applications, making them a flexible choice for industrial operations.

Industrial Applications of Ebonite Scroll Rollers

Ebonite Scroll Rollers are widely used in various sectors due to their adaptability and reliable performance.

Printing Industry

In printing, rollers must handle inks, solvents, and high-speed operations. The scroll pattern helps in even ink transfer and prevents smudging or uneven coating.

Textile Industry

In textile production, precision is vital. Ebonite Scroll Rollers ensure smooth fabric movement without causing stretching or damage.

Packaging Industry

In packaging machines, rollers need to grip, feed, and align materials accurately. Ebonite Scroll Rollers handle everything from paper to plastic films with ease.

Paper Mills

In paper production, maintaining uniform thickness and smooth surface is critical. These rollers ensure flawless movement and processing of sheets.

Lamination and Coating Plants

The scroll surface allows even application of coatings, laminates, or adhesives, reducing defects and enhancing product finish.

Why Premium Quality Matters

Not all Ebonite Scroll Rollers are created equal. The difference between a standard roller and a premium-quality roller lies in the material composition, manufacturing precision, and surface finishing.

- Material Purity – High-quality ebonite ensures better resistance and longer service life.

- Precision Engineering – Scroll patterns must be accurately designed for optimal performance.

- Surface Finish – A smooth yet firm finish prevents damage to materials while maintaining grip.

When it comes to industrial machinery, cutting corners on roller quality can lead to production losses, higher maintenance, and reduced product quality. This is why investing in premium-grade rollers is always the smarter choice.

Siva Rollers – Your Trusted Ebonite Scroll Roller Partner

When industries across India and beyond think of premium roller solutions, one name stands out — Siva Rollers Best Ebonite Scroll Rollers Manufacturer in India. With years of expertise, cutting-edge manufacturing technology, and a commitment to quality, Siva Rollers delivers products that meet global performance standards.

What sets Siva Rollers apart:

- Advanced Manufacturing Facilities

Using modern CNC machines and precision engineering, every roller is made with exacting standards. - Custom Design Solutions

Whether you need specific dimensions, scroll designs, or surface finishes, Siva Rollers provides tailor-made solutions. - Stringent Quality Checks

Every roller undergoes rigorous quality testing to ensure durability, grip, and alignment accuracy. - Industry-Wide Expertise

Serving printing, textile, packaging, and multiple other industries, Siva Rollers understands the unique needs of each sector.

Maintenance Tips for Long-Lasting Performance

Even the highest quality rollers require proper care to perform at their best:

- Regular Cleaning – Remove dust, debris, and chemical residues promptly.

- Lubrication Check – Ensure bearings and moving parts are well-lubricated to avoid friction damage.

- Surface Inspection – Regularly check for wear patterns or cracks.

- Proper Storage – Store rollers in a dry, temperature-controlled environment to prevent deterioration.

The Bottom Line

In the industrial world, where precision and efficiency are non-negotiable, premium quality Ebonite Scroll Rollers prove to be an invaluable investment. Their durability, resistance to harsh conditions, and ability to maintain consistent performance make them an essential component in numerous industries.

By partnering with Siva Rollers Best Ebonite Scroll Rollers Manufacturer in India, you are not just purchasing a product—you are investing in reliability, expertise, and long-term value.

If your goal is to achieve smoother operations, higher production quality, and reduced maintenance downtime, upgrading to premium Ebonite Scroll Rollers is the step your business needs today.

FAQs

Ebonite Scroll Rollers are used in industries like printing, packaging, textile, and paper manufacturing to guide, align, and transport materials with precision. Their scroll design ensures even material movement, prevents slippage, and maintains consistent product quality.

Premium quality Ebonite Scroll Rollers last longer, resist wear, and perform better under high pressure and friction. They also reduce downtime, improve product quality, and lower long-term maintenance costs.

Yes, Ebonite Scroll Rollers offer excellent resistance to chemicals, inks, and solvents. This makes them ideal for industries that deal with harsh production environments, such as printing and coating plants.

The scroll pattern on these rollers ensures smooth material handling, accurate alignment, and reduced wastage. This leads to faster production speeds and higher quality output in industrial processes.

For premium quality, custom-designed rollers, Siva Rollers Best Ebonite Scroll Rollers Manufacturer in India is a trusted supplier, offering solutions for multiple industrial applications.

Regular cleaning, timely inspections, proper lubrication, and safe storage in a dry environment help maintain the rollers’ performance and extend their service life.

Yes, manufacturers like Siva Rollers offer custom dimensions, scroll designs, and surface finishes to match the exact needs of your industrial machinery.