Calender Roller for Paper, Textile & Plastic Industry – Applications & Uses

In industries like paper, textile, and plastic manufacturing, the calender roller plays a critical role in achieving precision, surface finish, and product consistency. A roller calendar system is designed to press, smoothen, laminate, or finish materials under controlled pressure and temperature. Whether it is enhancing paper gloss, texturizing fabrics, or ensuring plastic sheets maintain accurate thickness, calendar rollers are indispensable. Selecting the right roller not only improves production efficiency but also extends equipment life, reduces downtime, and ensures a higher return on investment.

At the forefront of this technology, Siva Rollers is recognized as the Best Calender Roller Manufacturer in Ahmedabad, India, providing durable, high-performance rollers tailored for multiple industrial applications.

Understanding Calender Rollers in Industrial Applications

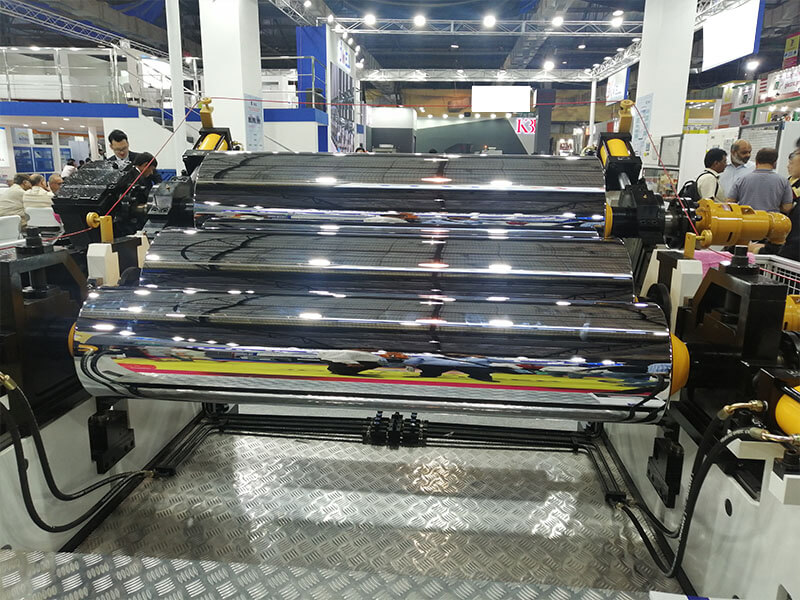

A calender roller is a heavy-duty roller used in a machine setup where materials like paper, fabric, rubber, or plastic are passed through multiple rolls to achieve desired thickness, finish, or surface characteristics. These rollers are usually made from steel or cast iron and often feature specialized coatings like chrome plating, rubber lining, or composite materials to suit the application.

The design and grinding quality of the roller are critical. Precision calender roll grinding ensures the roller surface is perfectly balanced, defect-free, and capable of delivering consistent results under high-pressure operations. Without proper grinding and surface finish, defects such as uneven thickness, rough surfaces, or poor lamination can compromise the final product.

Calender Roller in the Paper Industry

In paper mills, calendar rollers are used in the calendering section of the machine to control thickness, smoothness, and gloss. When paper passes between two or more rollers, the fibers compress, resulting in a smooth and uniform sheet. This process is essential for producing writing paper, newsprint, packaging board, and specialty papers.

- High-gloss paper requires rollers with polished chrome-coated surfaces.

- Packaging paper benefits from rollers with precise calendering to achieve strength and durability.

- Specialty papers like thermal and carbonless papers depend on the roller calendar system for uniform coating and finish.

Investing in high-quality Calender Roller Manufacturer in India ensures long operational life and reduced maintenance, directly influencing productivity in paper plants.

Calender Roller in the Textile Industry

The textile industry relies heavily on calendering rollers in India for finishing fabrics. The process improves texture, adds luster, and controls thickness while enhancing overall fabric appearance. By passing fabrics between heated rollers, textiles can be embossed, glazed, or given a silky smooth feel.

- Cotton and polyester fabrics gain a glossy finish.

- Technical textiles, such as filtration fabrics, require uniform thickness for performance.

- Embossed calender rollers can create decorative textures and patterns.

For textile manufacturers, the reliability of the calender roller is vital. Poorly finished rollers can cause streaks, uneven finishes, or fabric damage. This is why manufacturers prefer robust solutions from a trusted calender roller manufacturer.

Calender Roller in the Plastic Industry

Plastic sheet and film manufacturers use calendar rollers to control the thickness, clarity, and surface finish of their products. Whether producing PVC sheets, laminated films, or specialty plastic products, the role of the roller is to provide accurate compression and smoothness.

- Rollers ensure consistent gauge control in PVC sheets.

- In film manufacturing, rollers enhance transparency and prevent surface defects.

- Lamination processes use heated rollers to bond layers seamlessly.

Here, calender roll grinding becomes even more important since even minor imperfections can result in visible defects in transparent or glossy plastics. By working with an experienced Calendering Roller in India provider, plastic manufacturers can ensure precision and efficiency in every production run.

Why Calender Roll Grinding is Essential

The performance of a roller calendar is only as good as its grinding quality. Over time, rollers may develop surface wear, uneven coating, or alignment issues. Precision calender roll grinding restores rollers to their original specifications, ensuring:

- Smooth surface finish for defect-free production.

- Accurate roll diameter for consistent product thickness.

- Extended service life of the roller and reduced downtime.

Professional grinding also prevents vibration and heat generation during operations, reducing strain on machinery and improving product consistency.

Key Advantages of High-Quality Calender Rollers

Investing in superior quality calendar rollers in India offers a range of advantages across industries:

- Consistency – Uniform finish and thickness across paper, textiles, and plastics.

- Durability – Rollers with precision grinding and high-grade materials last longer.

- Efficiency – Minimized downtime and reduced maintenance costs.

- Customization – Rollers can be designed with specific surface coatings and hardness to suit unique industrial needs.

These advantages not only improve product quality but also give manufacturers a competitive edge.

Choosing the Right Calender Roller Manufacturer

Selecting the right calender roller manufacturer is crucial for industries that demand reliability and precision. A trusted manufacturer provides:

- Custom design and material selection.

- Advanced calender roll grinding facilities.

- Expertise across multiple industries.

- After-sales support and roller reconditioning services.

This is where Siva Rollers stands out as the Best Calender Roller Manufacturer in Ahmedabad, India. With years of expertise, advanced infrastructure, and a customer-centric approach, Siva Rollers delivers rollers that meet the highest performance and durability standards. Their solutions are trusted by leading paper mills, textile units, and plastic manufacturers across India.

Final Thoughts

The calender roller is more than just a machine component—it is a vital element in ensuring smooth operations, superior finish, and consistent output across the paper, textile, and plastic industries. From surface gloss in paper to texture in textiles and thickness control in plastics, calendar rollers define quality at every stage.

With growing demand for precision and efficiency, choosing a reliable Calender Roller Manufacturer in India has never been more important. Whether you require new rollers, reconditioned ones, or precision calender roll grinding, partnering with a trusted expert ensures long-term performance and value.

For manufacturers looking for robust, high-performance solutions, Siva Rollers is the Best Calender Roller Manufacturer in Ahmedabad, India, delivering expertise, technology, and trust in every product.

FAQs

A calender roller is a precision-engineered roller used in machines to compress, smooth, or finish materials like paper, textiles, and plastics. It controls thickness, enhances surface finish, and ensures consistent quality.

In the paper industry, calender rollers are used to improve sheet thickness, smoothness, and gloss. They help produce high-quality printing paper, packaging paper, and specialty papers with uniform finish.

Textile manufacturers use calender rollers for finishing fabrics, adding gloss, controlling thickness, and embossing patterns. They improve fabric texture and enhance the final appearance of cotton, polyester, and technical textiles.

In plastics, calender rollers ensure uniform thickness, clarity, and surface smoothness in PVC sheets, laminated films, and specialty plastic products. They also support lamination and bonding processes.

Calender roll grinding maintains the roller’s surface precision, diameter, and balance. It prevents surface defects, improves product consistency, extends roller life, and reduces downtime in production.

Calender rollers are typically made from high-grade steel or cast iron and are often coated with chrome, rubber, or composite materials, depending on the specific application.

Look for a manufacturer with proven expertise, custom design capabilities, advanced grinding technology, and strong after-sales support. Siva Rollers in Ahmedabad is one of the most trusted Calender Roller Manufacturers in India.

The lifespan of a calender roller depends on material quality, grinding precision, operating conditions, and maintenance. With proper care and professional grinding, rollers can last many years.

You can source durable, precision-engineered calender rollers from Siva Rollers – Best Calender Roller Manufacturer in Ahmedabad, India, offering customized solutions for paper, textile, and plastic industries.