How Ebonite Coated Rollers Can Transform Your Industry Workflow – Expert Guide

In today’s competitive manufacturing landscape, efficiency, precision, and durability are non-negotiable. One of the most overlooked yet critical components in various industrial processes is the roller. Among them, Ebonite Coated Rollers have emerged as a game-changer, providing enhanced performance, longevity, and workflow optimization. This expert guide explores how these rollers can transform your industry operations, with actionable insights for businesses across India.

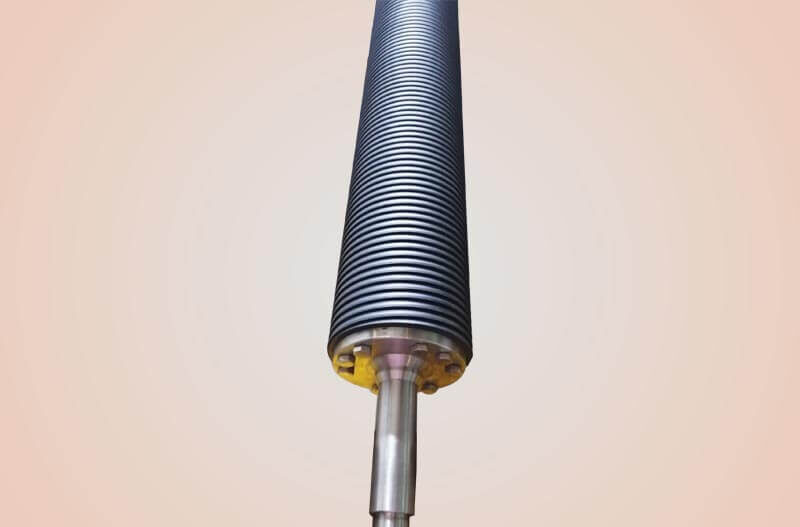

What is an Ebonite Coated Roller?

An Ebonite Coated Roller is a roller coated with ebonite—a hard, vulcanized rubber known for its exceptional durability, chemical resistance, and smooth finish. Ebonite’s unique properties make it suitable for high-pressure industrial applications where surface integrity, resistance to wear, and consistency are essential.

Key attributes include:

- High Hardness: Ebonite coatings provide a durable surface that withstands abrasion and high operational pressure.

- Chemical Resistance: Ideal for industries handling inks, adhesives, or chemicals.

- Low Maintenance: Less frequent replacements and minimal downtime.

- Precision Finish: Ensures consistent material handling and printing quality.

Manufacturers like Siva Rollers, a leading Ebonite Coated Rollers Manufacturer in Ahmedabad, India, specialize in producing tailored solutions for diverse industries.

Industries Benefiting from Ebonite Coated Rollers

Ebonite rollers have applications across multiple sectors, thanks to their versatility and reliability. Some of the primary industries include:

- Printing & Packaging

- Flexographic Printing: Smooth, chemically resistant ebonite surfaces ensure uniform ink transfer.

- Packaging Films: Reduces slippage and improves print accuracy on thin films.

- Example: An Indian packaging plant reduced print defects by 30% after switching to ebonite-coated rollers.

- Textile Industry

- Fabric Finishing: Ebonite rollers maintain consistent tension and pressure, reducing fabric distortion.

- Calendering Process: Enhances surface finish and uniformity.

- Benefit: Improves product quality while reducing machine downtime.

- Paper Industry

- Coating & Laminating: Ensures smooth application of coatings without scratches or marks.

- Moisture Resistance: Ebonite resists water and chemicals used in paper finishing.

- ROI Example: Paper mills in Gujarat reported a 20% longer roller life compared to traditional rubber rollers.

- Plastic & Film Industry

- Film Extrusion & Laminating: Prevents adhesion, ensuring clean processing.

- Thermal Resistance: Withstands heat generated during high-speed operations.

By using Industrial Ebonite Rollers, companies can reduce material waste, improve production efficiency, and achieve higher-quality end products.

Key Advantages of Using Ebonite Coated Rollers

The benefits of integrating ebonite-coated rollers into your workflow extend beyond durability. Here’s how they can transform operations:

- Enhanced Operational Efficiency

- Reduced Downtime: Long-lasting ebonite coatings require fewer replacements.

- Smooth Workflow: Consistent roller performance prevents jamming and production delays.

- Case in Point: A textile factory in West Bengal improved throughput by 15% after replacing old rollers with ebonite-coated ones.

- Superior Product Quality

- Consistent Finish: Ebonite ensures uniform pressure and smooth material handling.

- Chemical Compatibility: Maintains integrity even when processing inks, adhesives, or solvents.

- Example: Flexographic printing units in Maharashtra reported fewer print defects and sharper designs.

- Cost Savings & ROI

- Longer Lifespan: Ebonite rollers can last 2–3 times longer than conventional rubber rollers.

- Reduced Maintenance Costs: Less frequent servicing and replacements lower operational expenses.

- ROI Insight: Investing in high-quality Ebonite Coated Rollers often recoups initial costs within 12–18 months due to productivity gains.

- Versatility Across Applications

- Wide Temperature Range: Suitable for hot, cold, or high-friction environments.

- Industry Flexibility: Works with printing inks, adhesives, resins, and more.

How Ebonite Coated Rollers Improve Workflow – Step by Step

Integrating ebonite rollers into your production line requires an understanding of their impact on workflow. Here’s a stepwise guide:

Step 1: Evaluate Process Needs

- Identify critical points where rollers influence material handling or quality.

- Determine chemical exposure, temperature ranges, and pressure requirements.

Step 2: Select the Right Ebonite Roller

- Hardness Selection: Choose soft, medium, or hard ebonite based on application.

- Size & Finish: Ensure compatibility with your machinery for optimal performance.

- Consult experts from reputable Ebonite Coated Rollers Manufacturer for customized solutions.

Step 3: Install and Calibrate

- Proper alignment is crucial for uniform pressure and minimal wear.

- Use skilled technicians for installation to avoid surface damage.

Step 4: Monitor Performance

- Regularly inspect for surface wear, chemical degradation, or mechanical misalignment.

- Maintain lubrication and cleaning routines to extend roller life.

Step 5: Optimize Production

- Analyze data on roller performance, material output, and defect rates.

- Adjust operational speed and tension to leverage the roller’s full potential.

Choosing the Right Ebonite Coated Roller Manufacturer in India

India hosts several industrial roller manufacturers, but selecting the right partner is crucial. Consider the following:

- Expertise & Technical Support

- Look for manufacturers with decades of experience in ebonite coatings.

- Expertise ensures accurate hardness selection, coating thickness, and surface finish.

- Custom Solutions

- Industries often need tailored rollers for specific machines or processes.

- Leading manufacturers provide design consultation, prototyping, and testing.

- Quality Assurance

- Certified production processes (ISO, ASTM standards) ensure consistency.

- Verify durability, chemical resistance, and performance before purchase.

- After-Sales Service

- Timely support and maintenance advice reduce operational downtime.

- Example: Siva Rollers, a trusted Ebonite Coated Roller Manufacturer in Ahmedabad, India, offers on-site support and replacement guidance.

Buying Ebonite Coated Rollers in India – Key Considerations

When you plan to Buy Ebonite Coated Roller for your plant, consider these factors:

- Material Specifications: Confirm ebonite grade and hardness for your application.

- Surface Finish: Smooth, defect-free coatings ensure product quality.

- Roller Dimensions: Diameter, length, and shaft specifications must match your machinery.

- Operational Compatibility: Check temperature tolerance, chemical exposure, and load capacity.

- Supplier Reliability: Choose a manufacturer with proven track record and references.

Tips for Maximizing the Benefits of Ebonite Rollers

- Regular Cleaning: Prevent accumulation of adhesives or ink residues.

- Monitor Pressure: Maintain consistent operational pressure for uniform wear.

- Lubrication: Use manufacturer-recommended lubricants to extend life.

- Scheduled Replacement: Replace rollers before noticeable surface wear impacts output.

Why Siva Rollers is a Trusted Choice

For industries across India seeking high-performance Ebonite Coated Rollers, Siva Rollers stands out due to:

- Expertise in custom roller design for printing, textile, paper, and plastic industries.

- Commitment to quality, durability, and precision.

- Competitive pricing with high ROI potential.

- On-site support and consultation for optimal workflow integration.

Final Thoughts

The integration of Ebonite Coated Rollers into industrial workflows is no longer optional—it’s a strategic move for any manufacturing business aiming for efficiency, quality, and cost-effectiveness. From printing and packaging to textiles, paper, and plastics, these rollers ensure smooth operations, superior product finishes, and tangible ROI.

By choosing the right Ebonite Coated Rollers Manufacturer, businesses in India can access high-quality solutions designed to meet their unique needs. Whether you aim to reduce downtime, improve product consistency, or enhance overall workflow, investing in ebonite-coated rollers delivers measurable benefits.

Upgrade your production line today with Industrial Ebonite Rollers and experience a transformation in operational performance.

CTA: Ready to revolutionize your workflow? Buy Ebonite Coated Roller from Siva Rollers and see the difference in your industrial process efficiency.

FAQs

An Ebonite Coated Roller is a roller covered with hardened ebonite rubber, providing superior durability, chemical resistance, and smooth surface finish. These rollers are widely used in printing, packaging, textile, and paper industries for consistent material handling.

Industrial Ebonite Rollers are ideal for:

- Printing & packaging (flexography, laminating films)

- Textile calendering & finishing

- Paper coating & laminating

- Plastic film processing

They enhance efficiency, reduce downtime, and improve product quality across these sectors.

By offering consistent pressure, chemical resistance, and smooth rotation, Ebonite Coated Rollers minimize production errors, reduce material wastage, and optimize line speed, directly enhancing workflow efficiency.

The lifespan depends on application, maintenance, and operating conditions. On average, Ebonite Rollers in India last 2–3 times longer than traditional rubber rollers, offering significant ROI due to reduced replacements and downtime.

Yes. Leading Ebonite Coated Rollers Manufacturers, such as Siva Rollers, provide tailored solutions with custom diameter, length, hardness, and surface finish to suit your machinery and industry needs.

Regular cleaning, inspection for wear, lubrication, and monitoring of operational pressure are sufficient. Proper care ensures optimal performance and extends roller life.

Absolutely. Ebonite’s chemical resistance makes it suitable for inks, adhesives, solvents, and other industrial chemicals, ensuring smooth operations without surface degradation.

Consider factors like:

- Material hardness and ebonite grade

- Roller diameter, length, and shaft specifications

- Operational temperature and pressure

- Chemical compatibility with your processes

Consulting a trusted Ebonite Coated Rollers Manufacturer ensures the best fit.

They are used in offset, flexographic, gravure printing, lamination machines, and packaging equipment for smooth handling and consistent output.

Prices vary depending on size, hardness, and customization. While initial investment may be higher than standard rollers, the long lifespan and efficiency gains often provide ROI within 12–18 months.

Siva Rollers is a leading Ebonite Coated Rollers Manufacturer in Ahmedabad, India, offering:

- Customized industrial roller solutions

- High-quality, durable ebonite coatings

- Expert consultation and after-sales support

- Proven performance across printing, textile, paper, and plastic industries