Why Choose Rubber Coated Rollers for Printing, Packaging & Textile Applications?

In today’s fast-paced industrial world, efficiency, precision, and durability define success. From printing houses producing millions of impressions daily to textile mills running continuous fabric treatments, rollers play a crucial role in ensuring smooth, consistent, and high-quality output. Among the different types of rollers available, rubber coated rollers stand out as a versatile and cost-effective choice.

Whether you are in the printing industry, packaging sector, or textile manufacturing, selecting the right roller can directly impact performance, product quality, and operational costs. In this blog, we’ll explore why rubber coated rollers are the preferred choice, what makes them superior, and how partnering with a trusted rubber coated roller manufacturer in India can give your business a competitive edge.

Understanding Rubber Coated Rollers

A rubber coated roller is essentially a metal core (usually steel, aluminum, or stainless steel) covered with a specially formulated rubber layer. The rubber coating can be customized in terms of:

- Material composition (natural rubber, EPDM, nitrile, silicone, etc.)

- Hardness (measured in Shore A)

- Surface finish (smooth, grooved, or patterned)

- Diameter and length depending on the machine’s requirement

These rollers are widely used in printing, laminating, coating, embossing, and textile processing due to their excellent grip, shock absorption, and resistance to wear and tear.

Why Rubber Coated Rollers Are Essential for Printing, Packaging & Textile Industries

- Superior Grip and Traction

In applications where consistent contact and pressure are vital—such as printing rollers in India—rubber coatings provide exceptional grip. This ensures:

- Uniform ink transfer in printing presses

- Accurate film feeding in packaging machines

- Smooth fabric movement in textile processes

- Shock Absorption and Vibration Control

Unlike bare metal rollers, rubber-coated rollers absorb mechanical shocks and vibrations. This reduces machine wear, improves stability, and ensures long-term operational reliability.

- Resistance to Chemicals and Heat

Depending on the type of rubber used, these rollers can resist solvents, inks, adhesives, and even high processing temperatures. For example:

EPDM rubber rollers resist heat and ozone in textile finishing.

Nitrile rubber rollers perform well with oil- and solvent-based inks in printing.

Silicone-coated rollers withstand extreme heat in packaging applications.

- Cost-Effective and Durable

While metal rollers may wear out faster under constant friction, rubber rollers offer longer service life, reducing downtime and replacement costs.

- Customization Flexibility

A rubber coated roller manufacturer in India can tailor rollers to meet your specific needs—whether it’s hardness adjustment, surface patterning, or specialized chemical resistance.

Applications of Rubber Coated Rollers

Printing Industry

- Offset Printing: Ensures precise ink transfer to paper.

- Flexographic Printing: Maintains consistent pressure for clean impressions.

- Gravure Printing: Provides uniform contact for high-quality image reproduction.

Packaging Industry

- Lamination: Rubber rollers guarantee bubble-free bonding of films.

- Slitting and Rewinding: Smooth film handling without wrinkles or misalignment.

- Adhesive Coating: Ensures even spread of glue or adhesive solutions.

Textile Industry

- Dyeing and Finishing: Rollers regulate fabric feed and ensure uniform treatment.

- Calendering: Imparts smoothness and desired finish to fabrics.

- Printing on Fabrics: Transfers colors evenly, ensuring vibrant prints.

Key Advantages of Rubber Coated Rollers

Here’s a quick snapshot of why industries rely on them:

- Excellent surface protection for delicate materials

- Uniform pressure distribution for consistent results

- Reduced machine wear due to shock absorption

- Long-lasting with minimal maintenance

- Cost-effective compared to frequent metal roller replacements

Factors to Consider When Choosing Rubber Coated Rollers

Before investing in rollers, businesses must evaluate:

- Material Type

- Nitrile: Best for solvent- and oil-based applications

- EPDM: Excellent heat and weather resistance

- Silicone: Ideal for high-temperature packaging and textiles

- Natural Rubber: Great for general-purpose use

- Hardness (Shore A Rating)

- Soft rollers (30–50 Shore A): Better for delicate substrates

- Medium hardness (60–70 Shore A): Versatile across industries

- Hard rollers (80–90 Shore A): Suitable for heavy-duty applications

- Surface Finish

- Smooth: For uniform pressure and fine printing

- Grooved: To aid in liquid distribution

- Patterned: For specialized textile or coating applications

- Manufacturer Expertise

Working with an experienced rubber coated roller manufacturer in India ensures proper material selection, quality checks, and reliable after-sales support.

Why Partner with a Rubber Coated Roller Manufacturer in India?

India has become a global hub for industrial rollers due to competitive pricing, skilled manufacturing, and strict quality standards. Choosing a rubber coated roller manufacturer in India gives you:

- Cost Advantage: High-quality rollers at affordable prices compared to global markets

- Customization Capabilities: Ability to tailor rollers for unique machine needs

- Faster Lead Times: Quick production and delivery across India and abroad

- Global Standards: Many Indian manufacturers follow ISO and international benchmarks

- Trust & Reliability: Years of expertise in serving industries like printing, packaging, and textiles

When searching for a rubber coated roller manufacturer in India, always look for proven experience, testimonials, and after-sales service.

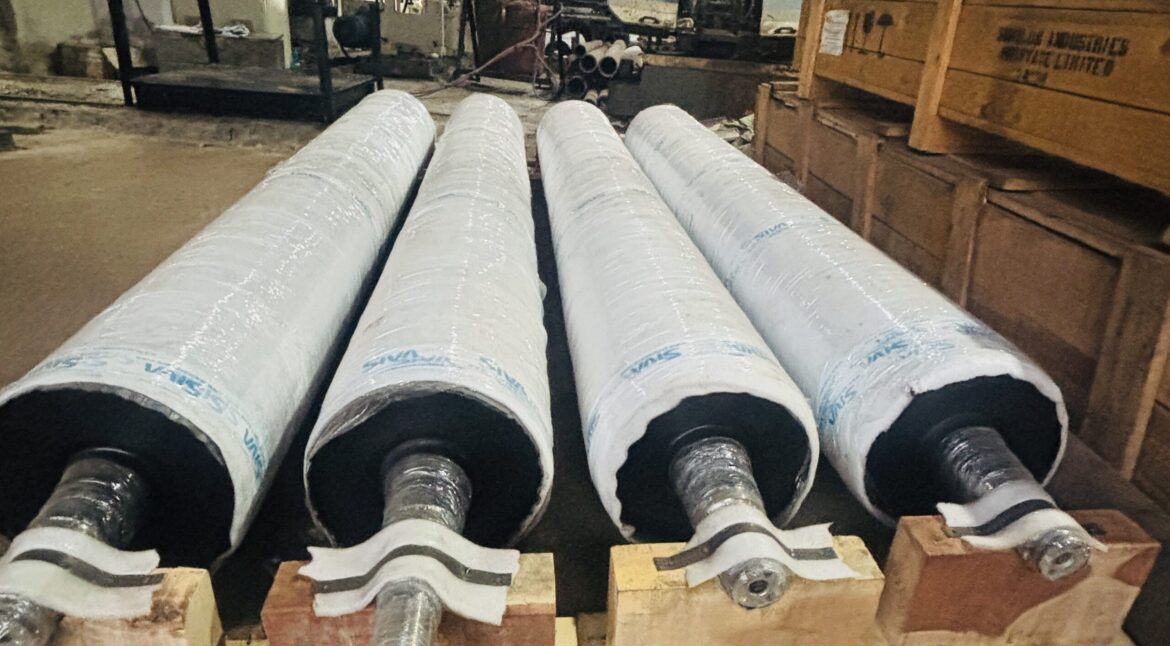

Why Siva Rollers Is the Trusted Name in Rubber Coated Rollers

At Siva Rollers, we specialize in manufacturing precision-engineered rubber rollers for diverse industries. With years of experience and advanced facilities, we deliver rollers that enhance machine performance and extend operational life.

Our key strengths include:

- Expertise in rubber roller coated India solutions for printing, packaging, and textiles

- Custom formulations based on application needs

- Stringent quality checks for durability and consistency

- Nationwide supply with reliable after-sales support

When you choose Siva Rollers, you’re choosing a partner committed to performance, quality, and long-term trust.

How Rubber Coated Rollers Boost Productivity

A well-designed rubber coated roller doesn’t just perform its basic function—it improves overall production efficiency. Here’s how:

- Reduced downtime with longer-lasting rollers

- Lower rejection rates due to consistent quality output

- Energy savings as smooth rollers reduce machine load

- Enhanced speed while maintaining accuracy

This means businesses can achieve higher profitability with relatively lower operational costs.

Make the Smart Choice with Rubber Coated Rollers

The demand for precision, durability, and efficiency in printing, packaging, and textile industries makes rubber coated rollers an indispensable choice. From ensuring smooth ink transfer to enhancing fabric finishing, their role is critical in driving consistent and high-quality results.

By partnering with a reputed rubber coated roller manufacturer in India like Siva Rollers, you get not just a product but a long-term performance solution. Our expertise, customization capabilities, and commitment to quality make us the trusted choice for industries nationwide.

Ready to enhance your production efficiency with premium rubber rollers?

Contact Siva Rollers today to discuss your requirements and request a free quote.

FAQs

Rubber coated rollers offer superior grip, shock absorption, and resistance to chemicals and heat compared to bare metal rollers. They also reduce machine wear and last longer, making them a cost-effective choice for industries like printing, packaging, and textiles.

Yes, leading rubber coated roller manufacturers in India like Siva Rollers provide tailored solutions based on hardness, rubber material, surface finish, and dimensions to suit specific industrial applications.

The choice depends on your application. For example, nitrile rollers are best for solvent-based inks, EPDM rollers for high-heat environments, and silicone rollers for packaging and textile finishing. Consulting an expert manufacturer ensures the right selection.

No. Rubber rollers are low-maintenance compared to other options. With proper cleaning, periodic inspection, and timely re-coating, their lifespan can be extended significantly.

Indian manufacturers like Siva Rollers combine global quality standards with competitive pricing. They offer quick lead times, customization, and reliable after-sales support, making them a trusted choice both in India and internationally.

Yes. Many worn-out rollers can be re-coated with fresh rubber, saving costs and extending usability. Manufacturers like Siva Rollers provide professional roller re-coating and refurbishing services.