How to Get the Best Price on Custom Stainless Steel Guide Rollers (Quote Request Inside)

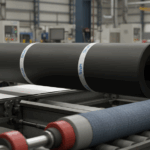

In modern manufacturing, every moving part contributes to the smooth rhythm of production. Whether it’s packaging, printing, textile, or material handling — guide rollers are among the quiet heroes of industrial machinery. They guide, align, and support materials as they move through complex systems, maintaining precision and consistency.

Among all roller materials, stainless steel remains the gold standard for performance and longevity. It’s strong, corrosion-resistant, and ideal for demanding environments where accuracy matters. And when precision meets customization — as in Custom Stainless Steel Guide Rollers — businesses gain more than just a component; they gain a performance advantage.

At Siva Rollers, one of India’s leading custom stainless steel roller manufacturers, each roller is built for excellence — engineered to meet specific industrial needs while offering long-term reliability. But before you buy, it’s important to understand what influences the price of custom stainless steel guide rollers, and how to get the most value for your investment.

Understanding Custom Stainless Steel Guide Rollers

Custom stainless steel guide rollers are specialized industrial rollers designed to control and guide the movement of materials across various manufacturing systems. They’re commonly used in:

- Conveyor systems for material transport

- Printing and packaging machines for film and paper alignment

- Textile and paper industries for web guiding and finishing processes

- Metal and wood processing units for precise feed control

Unlike off-the-shelf rollers, custom rollers for industrial machines are engineered to match exact dimensions, surface finishes, and performance requirements. The result? Reduced downtime, enhanced product quality, and higher operational efficiency.

At Siva Rollers, every roller is a blend of precision engineering and material mastery, built to handle high loads, extreme temperatures, and continuous operation with minimal wear.

Factors That Influence the Price of Custom Stainless Steel Guide Rollers

When purchasing industrial guide rollers, it’s natural to ask — “What determines the cost?” While prices vary based on specifications and scale, here are the main factors that shape the final quotation:

Material Grade and Quality

The type of stainless steel used directly affects performance and cost. Grades such as SS304, SS316, and SS410 are common in industrial rollers, each offering different levels of corrosion resistance, strength, and durability.

High-grade materials are ideal for environments exposed to moisture, chemicals, or heat — like food processing, printing, or textile applications. Investing in the right material ensures longevity and reduces maintenance costs in the long run.

Size, Diameter, and Length Specifications

Every millimeter matters. Larger rollers or those with unique dimensional requirements often require more raw material, machining time, and specialized tooling — all of which impact cost.

For instance, heavy-duty stainless steel guide rollers designed for wide conveyors or industrial laminators need thicker walls and precision balancing to prevent vibration and ensure stability.

Surface Finish and Coating Requirements

The surface finish determines how the roller interacts with materials. Polished, mirror, or textured surfaces may be required depending on the application. Some rollers may also feature Teflon, PU (polyurethane), or hard chrome coatings to enhance grip or resistance.

Customized surface finishing adds to the production complexity, influencing both price and performance.

Customization and Engineering Complexity

Custom rollers aren’t just machined — they’re designed to perform under specific load and speed conditions. Advanced manufacturing processes, like CNC precision turning and dynamic balancing, ensure accuracy and smooth operation.

Features such as special shafts, end caps, bearings, or integrated mounts add engineering complexity — and with it, cost. However, these customizations often pay off through improved performance and reduced machine wear.

Quantity and Order Volume

Ordering in bulk often reduces per-unit costs, as setup and tooling expenses are distributed across multiple rollers. For OEMs and large-scale users, establishing a long-term partnership with a stainless steel rollers supplier in India like Siva Rollers ensures consistent quality and optimized pricing.

Lead Time and Production Urgency

Expedited manufacturing requests may increase production costs due to overtime labor and scheduling adjustments. Planning your order in advance allows manufacturers to optimize workflow — often resulting in better pricing.

Choosing the Right Manufacturer: What to Look For

Not all rollers are created equal. Selecting the right guide roller manufacturer can mean the difference between months of smooth operation and repeated downtime. Here’s what to consider when evaluating a potential supplier:

Technical Expertise and Experience

Look for a manufacturer with proven experience in producing precision stainless steel rollers across multiple industries. Expertise ensures that every roller is engineered for precision alignment, concentricity, and perfect balance.

Siva Rollers, for instance, combines decades of industrial knowledge with advanced manufacturing technology to deliver consistent results.

Customization Capabilities

A top-tier custom stainless steel rollers manufacturer should be able to produce rollers tailored to your unique requirements — from shaft design to surface finishing.

At Siva Rollers, engineers collaborate directly with clients to design rollers that meet exact load, speed, and environmental specifications. This level of customization leads to optimal machine performance and longevity.

Material Testing and Quality Control

Trustworthy suppliers maintain strict quality control processes — including raw material inspection, hardness testing, runout checks, and dynamic balancing. These steps ensure every industrial guide roller meets tolerance standards and performs flawlessly under real-world conditions.

In-House Manufacturing and Technology

Working with a manufacturer that operates in-house facilities guarantees consistency and control. CNC machining, grinding, and polishing done under one roof allows for higher precision and faster turnaround times.

Siva Rollers’ state-of-the-art facility in Ahmedabad, India houses advanced machining and testing equipment, ensuring that every roller passes through rigorous quality checkpoints.

After-Sales Support and Consultation

The relationship doesn’t end at delivery. Reliable manufacturers provide installation guidance, performance consultation, and post-sales support. This ensures the rollers continue performing at peak efficiency long after installation.

How to Get the Best Price on Custom Stainless Steel Guide Rollers

Here are some smart, practical ways to optimize your investment when sourcing rollers:

- Define your specifications clearly. Provide exact dimensions, load capacity, and environmental details — it helps the manufacturer quote accurately and avoid unnecessary features.

- Plan for long-term needs. Ordering multiple rollers for future maintenance cycles can reduce per-unit costs.

- Choose quality over short-term savings. A cheap roller that fails early costs more in downtime and repairs than a durable one.

- Partner with an experienced manufacturer. Working directly with experts like Siva Rollers ensures fair pricing, consistent quality, and reliable delivery timelines.

- Request a detailed quotation. Instead of asking for “the cheapest roller,” ask for a customized quote based on your machine type, load, and performance requirements.

Why Siva Rollers is India’s Trusted Name in Custom Stainless Steel Guide Rollers

Siva Rollers stands among India’s most trusted names in industrial roller manufacturing, supplying custom stainless steel guide rollers to clients across packaging, printing, textile, paper, and metal industries.

What sets Siva Rollers apart:

- Precision Engineering: Every roller is dynamically balanced for smooth operation and extended machine life.

- Premium Materials: Only high-grade stainless steel and coatings are used for corrosion and wear resistance.

- Customization Expertise: From miniature rollers to heavy-duty designs, all rollers are made to exact client specifications.

- End-to-End Service: Design consultation, prototyping, mass production, and post-sales support — all under one roof.

As a leading stainless steel guide roller manufacturer in India, Siva Rollers ensures that every client gets unmatched quality, technical reliability, and cost-effectiveness.

Request Your Custom Quote Today

Whether you need durable stainless steel guide rollers for conveyor systems, precision-engineered custom rollers for packaging machinery, or heavy-duty rollers for industrial use — Siva Rollers delivers performance you can depend on.

Contact Siva Rollers today to request your custom stainless steel guide roller quote. Our team will analyze your requirements and provide a tailored solution designed for maximum efficiency and long-term value.

FAQs

They’re used in conveyor, packaging, printing, and material handling machines to guide and align materials precisely during production.

Stainless steel offers corrosion resistance, strength, and long service life, making it ideal for harsh industrial environments.

Roller size, material grade, surface finish, and customization level all influence the total price.

Define clear specifications, order in bulk, and partner with an experienced manufacturer like Siva Rollers for optimized pricing.

You can buy directly from Siva Rollers, a leading custom stainless steel guide roller manufacturer and supplier in India.