India Most Trusted Ebonite Rubber Roller Manufacturer Printing Line Stability, Superior Grip, and Profitable Long Life

Why India’s Industrial Buyers Demand Ebonite Rollers for Precision Printing

In the competitive landscape of Indian high-speed printing—from flexible packaging and label manufacturing to high-end publication graphics—every operational detail determines profit or loss. Suppose you are a printing industry owner, a maintenance head, or a procurement specialist. In that case, you know that consistent, high-quality output depends on the performance of one critical component: the ebonite rubber roller.

The search for the perfect roller isn’t just about replacing a worn part; it’s about finding a strategic solution that delivers stability, reliability, and unmatched longevity. Inferior rollers lead to production nightmares: uneven ink transfer, costly line stoppages, product rejection, and soaring maintenance expenditure.

This comprehensive guide is designed for the discerning industrial buyer. It explains why the Ebonite Rubber Roller stands as the industry standard for the most demanding applications, how it specifically addresses your critical printing problems, and why Siva Roller, India’s acclaimed Ebonite Roller Manufacturer, is the essential partner for achieving operational excellence across the entire nation.

Why Conventional Rollers Increase OpEx

Industrial buyers start their search when production problems begin to hit the balance sheet. Let’s detail the core challenges that force printing and packaging businesses to seek a superior component like the Ebonite Coated Roller:

A. The Challenge of Quality and Inconsistency

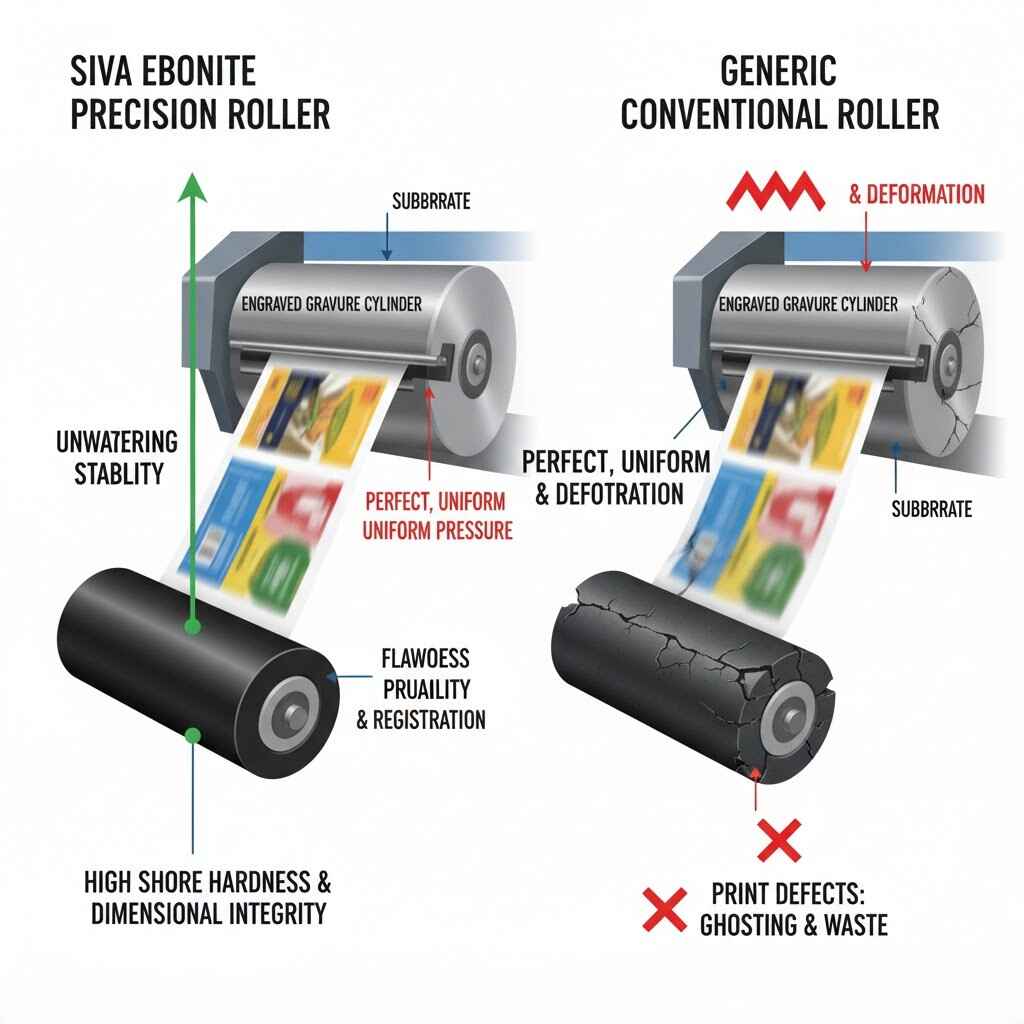

High-speed printing systems, particularly Gravure Printing Roller lines, require dimensional stability that standard rubber cannot always provide. Under the stress of high pressure and friction-induced heat, conventional rollers can experience subtle deformation. This minute change immediately causes print defects—ghosting, banding, or uneven coating thickness—leading to massive material waste and production bottlenecks. The inconsistency of the roller directly translates to inconsistent print quality.

B. The Corrosive Chemical Environment

Printing inks, powerful solvents, strong adhesives, and aggressive cleaning agents are the constant enemies of standard rubber. Many compounds are porous and absorb these chemicals, causing them to swell, lose hardness, crack, and soften prematurely. This chemical degradation is the primary driver of premature roller failure, requiring frequent replacement of costly Printing Machine Spares and leading to unplanned downtime.

C. The Menace of Static and Dust Contamination

Handling substrates like plastic film, delicate foil, or thin paper generates significant static electricity. This static charge acts like a magnet, attracting microscopic dust particles and debris. When these contaminants transfer to the printing plate or substrate, they cause defects, pinholes, and require frequent machine cleaning. This demands an Anti-static Rubber Roller solution—a specialty Ebonite can provide—that actively dissipates this electrical charge safely and permanently.

D. The High Total Cost of Ownership (TCO)

When a roller wears out quickly due to abrasion, heat, or chemical attack, the total operational expenditure (OpEx) skyrockets. The cost isn’t just the replacement price; it’s the cost of lost production time, labor for changeovers, disposal fees, and rushed logistics. Industrial buyers need a genuine “fit and forget” roller that reduces the frequency of needing Printing Machine Spares and extends the maintenance interval significantly.

Ebonite Technology: The Foundation of Printing Reliability

What Makes the Ebonite Roller Unique?

An ebonite rubber roller is built around a robust metal core (typically steel) with a thick, uniform coating of this specialized hard rubber compound. This construction provides the structural rigidity of metal combined with an exterior surface that is dimensionally stable, chemically inert, and highly durable.

The Triple-Pillar Advantage: Stability, Grip, and Durability

i. Unwavering Stability for Flawless Print Density

Dimensional stability is paramount for consistent print density and uniform coating. Ebonite is a highly rigid, unyielding material. It maintains its exact profile and does not significantly compress or deform under the extreme pressure and high operating temperatures of modern printing presses. This structural integrity guarantees that the roller maintains perfect parallelism across its entire face width, ensuring uniform contact pressure for perfect ink transfer and flawless coating applications, run after run.

ii. Consistent Grip for Smooth Substrate Handling

The precise, stable grip of an Ebonite Coated Roller is crucial for guiding high-speed substrates (film, paper, or foil) through the machine without wrinkling, stretching, or slippage. Its dense, non-tacky surface provides a highly reliable traction point, critical for maintaining web tension and ensuring alignment. This stability minimizes lateral and rotational substrate movement, preventing registration errors that are common in complex, multi-color Gravure Printing Roller processes.

iii. Exceptional Resistance and Durability for Long Life

Ebonite is the definition of a long-term investment. Its robust chemical matrix offers unparalleled resistance to the harshest industrial stressors, dramatically extending service life compared to standard rubber:

- Solvent and Chemical Resistance: Ebonite does not swell or soften when exposed to the aggressive solvents and cleaning agents necessary for maintaining Gravure Printing Roller and flexo lines.

- Abrasion and Wear Resistance: It withstands continuous, high-speed friction and shear forces without chipping, grooving, or premature wear.

- Heat Resistance: It maintains its critical hardness and dimensional form even when subjected to high operational heat, making it perfect for lamination and specialized Coating Roller lines.

This remarkable resilience ensures your Ebonite Roller lasts significantly longer, lowering your reliance on constant Printing Machine Spares and drastically reducing operational overhead.

Specialized Applications: Ebonite for High-Performance Lines

While foundational to general printing, the unique attributes of Ebonite are especially critical in three specialized areas:

The High-Precision Gravure Printing Roller

In gravure printing, the impression roller’s job is to press the substrate against the engraved cylinder with consistent, unyielding force. A slight pressure deviation can ruin the entire run. The high Shore hardness and dimensional stability of the Ebonite Roller ensure this precise, unfluctuating pressure is delivered. It is the gold standard for Gravure Printing Roller systems, maximizing dot integrity and achieving the deepest, most uniform color density required by high-end brands.

The Essential Coating Roller in Packaging

The flexible packaging industry relies on rollers for the uniform application of varnishes, adhesives, and specialized coatings. A reliable Coating Roller must distribute the fluid evenly without absorbing the chemicals, which would lead to surface deformation. The non-porous nature of the Ebonite compound prevents chemical ingress, ensuring consistent coating laydown, easy cleanup, and reliable performance in complex lamination processes.

Solving Static: The Anti-static Rubber Roller Solution

For businesses handling delicate, static-prone materials, the inclusion of a specialized Anti-static Rubber Roller is essential. By incorporating proprietary conductive compounds during manufacturing, Siva Roller engineers Ebonite rollers that safely and continuously dissipate static charge buildup. This results in:

- Cleaner production runs due to reduced dust attraction.

- Elimination of material sticking, wrinkling, and web breaks.

- Enhanced operator safety by preventing electrostatic discharge (ESD).

The Supply Chain Advantage for the Printing Roller Wholesaler

For Printing Roller Wholesaler businesses, distributors, and large-scale procurement agencies, the Ebonite Roller represents a premium, high-demand product. Stocking a product with an extended service life translates directly to lower warranty claims, reduced customer service load, and higher customer loyalty. This roller is a high-value asset that sells itself on proven quality and lasting performance.

Why Siva Roller is the Leading Ebonite Roller Manufacturer in India

Selecting the correct Printing Roller Manufacturer is not just a commercial choice; it’s a strategic decision for your factory’s future. For decades, Siva Roller has cemented its position as the most dependable Ebonite Roller Manufacturer in India and a highly reliable Ebonite Roller Supplier in India.

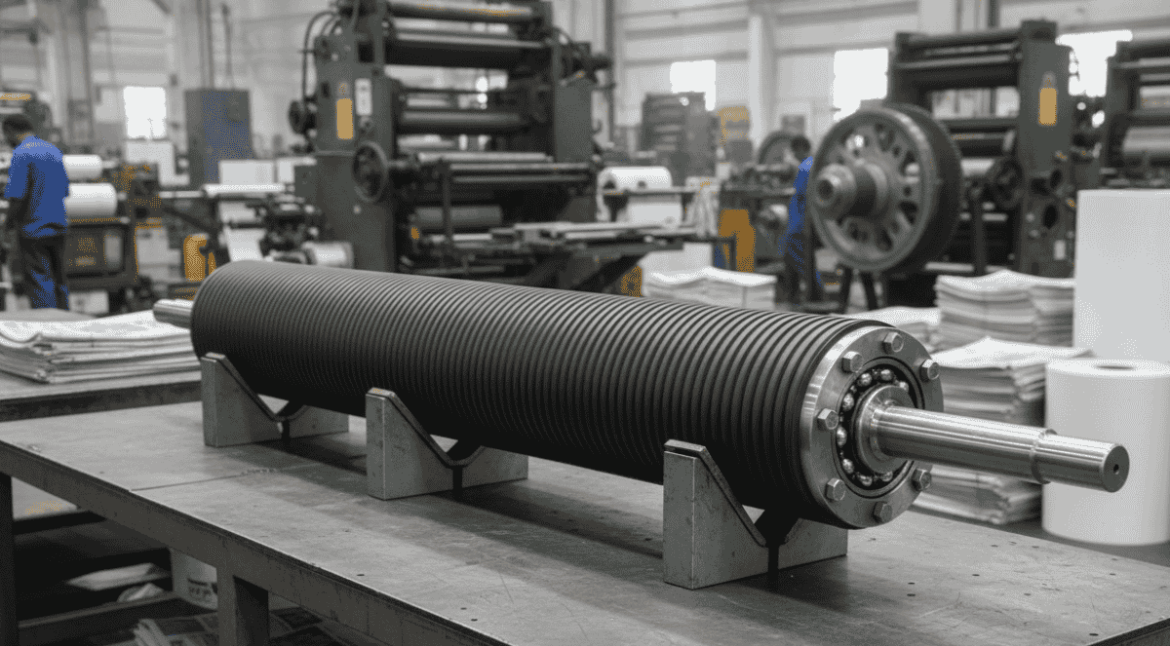

While our modern, state-of-the-art manufacturing plant is strategically located in Ahmedabad, Gujarat, our logistical network and application expertise allow us to serve every major industrial hub—from Mumbai and Delhi to Chennai, Kolkata, and beyond. We are a truly pan-India partner dedicated to quality that travels across the sub-continent.

Excellence Driven from Ahmedabad

Siva Roller’s commitment to being a market leader is built on three pillars of unmatched quality:

- Meticulous Material Formulation: We start with only the highest-grade raw materials and employ a meticulously controlled, high-heat vulcanization process. This ensures every ebonite rubber roller we produce consistently achieves the exact dimensional stability, Shore hardness, and superior chemical resistance required for high-stress industrial use.

- Precision Engineering and Finish: Our facilities in Ahmedabad are equipped with world-class grinding and finishing machinery. We guarantee perfect parallelism and an ultra-smooth surface finish, which is non-negotiable for critical applications like Gravure Printing Roller and Coating Roller systems.

- Customer-Centric Application Expertise: We don’t just supply products; we partner with you. Our engineering team collaborates to analyze your specific machinery, operational speed, ink chemistry, and substrate requirements to ensure you receive a custom-tailored Ebonite Coated Roller solution that guarantees maximum uptime and efficiency.

Streamlining Procurement Across India

As a leading Ebonite Roller Supplier in India, we are acutely focused on making your procurement process efficient and reliable:

- Reliable Logistics and Turnaround: Our centralized manufacturing base in Ahmedabad, Gujarat, enables quick production and efficient nationwide logistics. We ensure minimal lead times for both your regular orders and critical Printing Machine Spares.

- Guaranteed Consistency: Whether you are an industrial end-user or a high-volume Printing Roller Wholesaler, our rigorous Quality Control protocols ensure homogeneity in every aspect—from the chemical bonding of the rubber to the dynamic balance of the core.

- Lowest Total Cost of Ownership (TCO): Siva Roller operates on the principle that the lowest lifetime cost is more important than the lowest initial price. By providing a roller with proven superior long life and exceptional durability, we help your business achieve the lowest possible TCO for your printing components, making us the preferred Printing Roller Manufacturer for smart businesses.

Invest in Uncompromising Print Quality

If your printing operation is currently struggling with high replacement frequency, inconsistent print quality, excessive waste due to static, or costly chemical degradation, it is time to upgrade your component strategy.

The decision to invest in a high-quality Ebonite Roller from a trusted Printing Roller Manufacturer is a direct investment in your profitability, stability, and reputation.

The Siva Roller Performance Guarantee

For the printing industry owner, the decision to choose Siva Roller comes down to more than just product specifications—it’s about eliminating risk and guaranteeing sustained profitability. We don’t just supply rollers; we provide a performance contract:

- Financial Assurance (ROI Certainty): Our engineering quality is directly linked to your bottom line. By drastically extending roller life and minimizing machine downtime and waste, the Ebonite Roller delivers an immediate, measurable Return on Investment (ROI). The lowest Total Cost of Ownership (TCO), not the lowest initial price, is the metric that secures your long-term profit.

- The Partnership for Precision: We act as your specialized technical partner, ensuring the roller is perfectly matched to your gravure, flexo, or coating application. This personalized consultation prevents costly installation errors and optimizes performance from day one, giving you production certainty.

- Future-Proofing Your Line: Investing in Siva Roller’s durable, chemically inert, and thermally stable Ebonite means your press is ready for future innovations in inks, solvents, and higher operating speeds without requiring frequent component replacement.

Make the Strategic Choice. Guarantee Your Uptime.

Don’t let inconsistent, worn-out rollers dictate your production quality and profit margins. Contact the Siva Roller expert team today for a technical consultation and a customized quote. Invest in the long life, stability, and superior print quality that only India’s most trusted Ebonite manufacturer can deliver.

CONTACT US

FAQs

An Ebonite Rubber Roller is a hard-rubber–coated industrial roller made through a long vulcanization process. It delivers extreme rigidity, chemical resistance, and dimensional stability, making it ideal for high-speed printing, coating, and lamination lines.

Normal rubber deforms under heat, pressure, and solvents. Ebonite stays rigid, maintains its profile, and resists chemical swelling. This prevents print defects, reduces downtime, and increases roller life—making it the preferred choice for gravure, flexo, and coating lines.

Its hard, dimensionally stable surface maintains consistent pressure across the entire web width. This ensures uniform ink transfer, accurate registration, clean impression, and stable print density—crucial for premium packaging and publication work.

Yes. Ebonite’s non-porous structure prevents absorption of inks, solvents, adhesives, and cleaning chemicals. This protects the roller from swelling, cracking, and softness—major reasons for premature failure in conventional rollers.

Yes. When manufactured with conductive compounds, Ebonite functions as an Anti-static Rubber Roller. It continuously dissipates static, reducing dust attraction, web breaks, material sticking, and operator safety risks.

They are widely used in:

• Gravure and flexographic printing

• Packaging and lamination lines

• Coating and varnishing systems

• Paper, film, foil, and label manufacturing

• Textile printing and finishing

• Specialty industrial machines requiring high rigidity

Ebonite Rollers typically last 3–5 times longer due to their superior abrasion resistance, chemical stability, and heat tolerance. This reduces replacement frequency and lowers total cost of ownership.

Yes. Their hardness and rigidity ensure they don’t deform under high pressure or heat. This stability supports high-speed gravure and coating lines without compromising quality or alignment.

They eliminate issues such as:

• Ink variation and print inconsistency

• Ghosting, banding, and uneven coatings

• Frequent roller replacement

• Chemical swelling or surface softening

• Static buildup and dust contamination

• Substrate slipping, wrinkling, and registration errors

Siva Roller provides:

• High-grade raw material formulation

• Precision grinding and ultra-smooth finishing

• Anti-static and custom hardness options

• Reliable pan-India supply and fast logistics

• Proven long-life rollers tested for extreme industrial conditions

Yes. Siva Roller engineers each roller based on machine type, operating speed, ink chemistry, substrate, and application requirement. Custom hardness (Shore A/D), diameter, face width, and static-control properties are available.

Absolutely. Their long life and dimensional stability prevent sudden roller failures, reduce maintenance intervals, and ensure uninterrupted production—delivering measurable ROI for printing factories.

Yes. They are widely used as impression rollers in gravure, nip rollers in coating lines, and various support rollers in flexo presses. Their stiffness ensures clean impressions in all printing formats.

Use approved cleaning solvents, avoid sharp tools, store rollers horizontally on proper supports, and schedule periodic surface inspections. Ebonite requires minimal maintenance compared to other elastomers.

Siva Roller’s centralized facility in Ahmedabad ensures fast production and nationwide dispatch. Lead times vary by size and customization, but standard rollers are delivered quickly to minimize downtime.