Rubber Roller Manufacturer in Kolkata – Best Quality Rollers for Printing & Packaging Units

The industrial landscape of Kolkata, a vibrant hub for printing and packaging, moves at a rapid pace. In this environment, where deadlines are tight and quality is non-negotiable, one component holds more power over your operational success than almost any other: the Rubber Roller.

For plant owners, procurement managers, and maintenance engineers across West Bengal and, indeed, all of India, the roller isn’t just a part—it is the heart of production. When a roller fails, the entire line stops. When a roller performs poorly, the product quality drops, leading to costly waste and reputation damage.

This definitive guide is written specifically for you. We will dive deep into the real-world challenges faced by printing and packaging units and introduce you to the definitive solution for high-performance, durable, and reliable Industrial Rubber Roller products. Siva Roller, a leading Rubber Roller Manufacturer India, is committed to ensuring Kolkata’s industries run smoothly, efficiently, and profitably.

The Critical Role of the Industrial Rubber Roller: Why Quality is Non-Negotiable

In the world of high-speed manufacturing, the Industrial Rubber Roller is a quiet giant. Whether it’s precisely distributing ink onto a newspaper sheet or applying specialized adhesives for food packaging, these rollers perform thousands of critical contacts every hour.

The performance of your equipment—from gravure and flexographic presses to specialized laminating machines—is directly tied to the quality of the Rubber Coated Roller you use.

The Stake for Industrial Buyers:

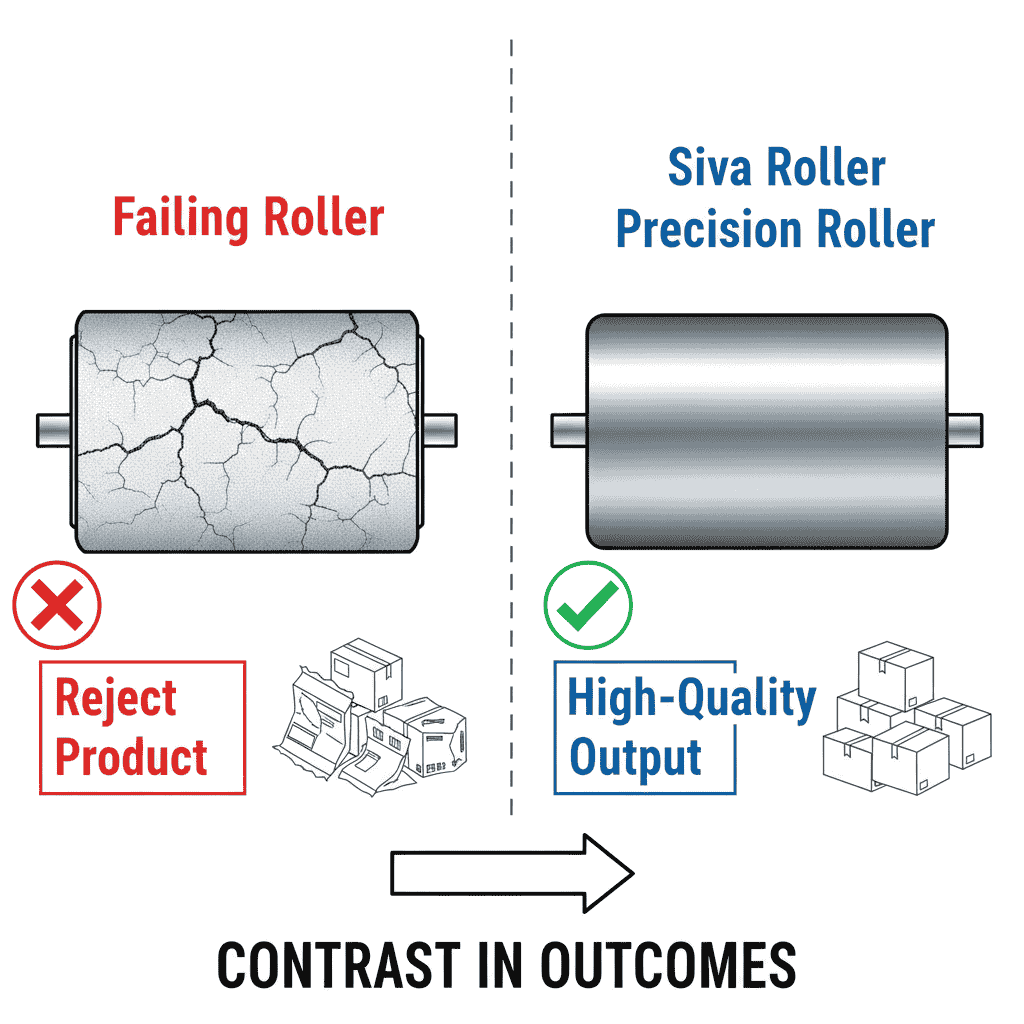

If you are a unit owner or a procurement specialist, your primary concern is Total Cost of Ownership (TCO). A cheaper roller might save you a few thousand rupees upfront, but if it causes unscheduled downtime, requires premature replacement, or results in 2% more rejected product, the “savings” evaporate instantly.

A superior Rubber Roller offers:

- Consistency: Perfect, edge-to-edge material transfer (ink, coating, adhesive).

- Durability: Resistance to the chemicals, solvents, and heat inherent in the processes.

- Precision: Maintaining shape and hardness under intense operational pressure.

Choosing the right Industrial Rubber Roller isn’t about buying a product; it’s about investing in operational peace of mind.

The Real Pain Points in Printing & Packaging

Industrial buyers often search for new suppliers because their current setup is causing specific, measurable, and costly problems. We understand these frustrations completely.

The Problem of Premature Degradation and Swelling

Have you ever noticed your rollers changing shape or becoming sticky after just a few months? This is often due to an inadequate polymer compound reacting with the harsh industrial chemicals—solvents, UV inks, cleaning agents—used daily.

A common search query we see is: “Why are my printing rubber roller surfaces cracking?”

The Buyer’s Challenge: High-volume printing and packaging units cannot afford unpredictable roller life. When a Rubber Coated Roller swells or cracks, it leads to uneven pressure and poor finish quality, forcing a complete halt to change the component. This downtime is the biggest cost to any industrial unit.

Inconsistent Ink Transfer and Ghosting

For offset printing rollers manufacturers and their customers, ink consistency is everything. Ghosting, streaking, or inconsistent colour density are direct results of a roller that cannot maintain uniform surface tension and hardness across its face. The roller might look fine, but internally, its structure may be failing, leading to micro-vibrations and uneven ink film distribution.

The Buyer’s Challenge: Every wasted sheet of expensive paper or film, every minute spent cleaning or adjusting the press, cuts into the profit margin. Operators need rollers that maintain their durometer (hardness) precisely, day in and day out, regardless of environmental factors like humidity or temperature changes common in Kolkata’s climate.

The Hidden Costs of Frequent Replacement

Many manufacturers focus only on the initial purchase price. However, the real burden is in the frequency of replacement, the labour cost of installation, and the inventory holding cost of spare rollers.

If your maintenance log shows frequent roller changes, it’s a clear sign that the base material or the coating process of your current supplier is subpar. You need a solution that maximizes the Mean Time Between Failures (MTBF).

The Buyer’s Challenge: You are looking for a Rubber Roller Manufacturer in India who stands behind the longevity of their product, providing a superior return on investment (ROI) through reduced replacement cycles.

Siva Roller: The Trusted Rubber Roller Manufacturer in India Serving Kolkata

When you are looking for an expert supplier of Rubber Roller products that solve the complex problems outlined above, the search leads you to Siva Roller.

While our state-of-the-art manufacturing plant is strategically located in Ahmedabad, Gujarat—a logistical hub that allows us to serve all major industrial centres swiftly—Siva Roller has established itself as the preferred Rubber Roller Manufacturer in India for Kolkata’s discerning printing and packaging units. We understand the specific demands of the Eastern Indian market and ensure prompt, reliable supply and localized support.

Built for Performance, Engineered for Durability

Siva Roller doesn’t just manufacture rollers; we engineer solutions. Our commitment is to eliminate the pain points of degradation, inconsistency, and premature wear, ensuring your machinery achieves maximum output.

What sets Siva Roller apart:

- Superior Compound Formulation: We utilize high-grade, chemical-resistant polymers specifically formulated to withstand aggressive solvents and high temperatures, drastically reducing roller swelling and surface cracking—a common nightmare for Industrial Rubber Roller users.

- Precision Grinding and Finishing: Our rollers are finished to exacting tolerances, ensuring perfect concentricity. This is absolutely vital for consistent pressure and flawless material transfer, eliminating the streaks and ghosting that plague high-quality print jobs.

- Targeted Hardness (Durometer): We consult with your team to supply the precise hardness needed for your specific machine and application, whether it’s a soft Rubber Coated Roller for lamination or a hard-wearing roller for heavy-duty flexographic presses.

Specializing in Printing Industry Rollers

The printing sector demands perfection. Siva Roller understands that a minor imperfection in the roller surface translates directly to a major defect on the printed material.

For both web and sheet-fed presses, our printing rubber roller range ensures:

- Uniform Ink Pickup and Delivery: Critical for colour accuracy and eliminating “pinholes” or un-inked spots.

- Solvent Resistance: Longevity in the face of harsh cleaning cycles and chemical exposure.

- Low Heat Build-up: Essential for high-speed runs where friction can compromise roller stability.

As dedicated offset printing rollers manufacturers, we provide components that integrate seamlessly with all major machinery brands, making installation and calibration straightforward and efficient.

How Siva Roller Solves the Packaging Unit’s Toughest Challenges

The packaging industry, particularly flexible packaging, requires versatility. Rubber Coated Roller products here must handle varying film types (BOPP, PE, PET, aluminum foil) and specialized coatings like adhesives or lacquers.

Applications Where Siva Roller Excels:

- Laminating and Slitting Rollers: For food-grade and medical packaging, the integrity of the lamination seal is paramount. Our rollers ensure uniform pressure and temperature distribution across the entire web width, guaranteeing a flawless, bubble-free bond.

- Drive and Nip Rollers: These rollers are responsible for the precise movement of packaging film. Any slipping or uneven grip can lead to misregistration, wastage, and incorrect sealing. Siva Roller’s durable Industrial Rubber Roller solutions maintain a consistent grip without damaging sensitive film surfaces.

Focus on Material Compatibility

One of the biggest struggles for buyers in packaging is matching the roller compound to the adhesive or coating material. Using an incompatible Rubber Roller leads to rapid material buildup, frequent cleaning, and surface pitting. Siva Roller’s team consults with you to recommend the exact polymer—be it EPDM, Silicone, Nitrile, or Polyurethane—that offers maximum resistance to the specific chemicals and processes in your plant.

This consultative approach, delivered by a top-tier Rubber Roller Manufacturer in India, ensures that the roller you install is not a gamble, but a guaranteed fit for purpose.

The Siva Roller Advantage: Investing in Efficiency and Future Growth

Choosing Siva Roller as your preferred Rubber Roller Manufacturer in Kolkata India is a decision to prioritize long-term efficiency over short-term savings. We help industrial buyers meet the demand for higher output and flawless quality that the Kolkata market expects.

Focusing on Durability, Not Downtime

Every feature we engineer into our Rubber Roller products is designed with one goal: reducing unscheduled maintenance and extending your production cycles. This commitment to longevity is what makes us a leading partner for both established offset printing rollers manufacturers and emerging packaging start-ups.

A Reliable Partner for Kolkata’s Industrial Future

While our manufacturing base is in Ahmedabad, Gujarat, our logistical network ensures that high-quality Rubber Coated Roller products are supplied efficiently to Kolkata. We pride ourselves on being accessible, providing detailed product specifications (without getting overly technical in this forum!) and transparent pricing, ensuring you can make a clear, confident buying decision.

For any printing unit requiring specialized printing rubber roller solutions or a packaging unit needing robust nip rollers, Siva Roller is structured to be your one-stop, pan-India supplier.

Take the Next Step Towards Operational Excellence

For the printing and packaging units of Kolkata and across India, the time for compromising on the quality of your Rubber Roller components is over. Siva Roller, as a leading Rubber Roller Manufacturer in India, provides the durable, high-precision solutions that eliminate unexpected downtime and elevate your product quality.

Don’t let subpar Industrial Rubber Roller products dictate your bottom line. Take control of your operational efficiency today. Whether you are searching for specific offset printing rollers manufacturers expertise or general Rubber Coated Roller durability, Siva Roller is ready to partner with you.

We serve Kolkata with the precision and reliability engineered in Gujarat. Contact Siva Roller now to consult with our experts and find the perfect, long-lasting Rubber Roller solution for your specific application. Invest in Siva Roller, and invest in guaranteed performance.

Contact Us

Emial : info@sivarollers.com

Phone Number :

FAQs

Siva Roller supplies high-precision, long-life Industrial Rubber Rollers engineered using superior polymer compounds and precision grinding. These rollers are built to withstand Kolkata’s high-humidity climate, high-speed printing conditions, and aggressive industrial chemicals, ensuring consistent performance and fewer breakdowns.

Roller selection depends on your machine type, ink or adhesive, substrate (paper, BOPP, PET, foil), operating temperature, and required hardness. Siva Roller’s technical team evaluates your process and recommends the ideal compound—EPDM, Nitrile, Silicone, or PU—to ensure maximum life and consistent output.

Premature swelling or cracking usually happens due to poor-quality compounds that react with solvents, UV inks, or cleaning chemicals. High heat and pressure also accelerate degradation. Siva Roller uses chemical-resistant polymers and advanced curing technology to eliminate early surface failure.

Roller life varies based on machine speed, cleaning methods, and chemical exposure. High-quality rollers last significantly longer—often 1.5× to 3× more than low-grade rollers. Buyers who shift to Siva Roller typically see longer MTBF (Mean Time Between Failures) and reduced downtime.

Durometer directly affects ink transfer, pressure uniformity, and finish quality. If hardness is incorrect, issues like ghosting, uneven coating, or slipping can occur. Siva Roller supplies rollers with exact hardness tailored to your application, ensuring stable print quality.

Print units commonly face ghosting, streaking, slippage, inconsistent ink transfer, pinholes, and frequent press cleaning. These issues occur when rollers lose shape or hardness. High-quality rollers ensure steady surface tension and perfect concentricity, eliminating such defects.

Yes. Despite being manufactured in Ahmedabad, Siva Roller maintains fast logistics coverage for Kolkata and all of West Bengal. Most standard rollers are ready for dispatch, and custom rollers are delivered with efficient lead times.

Absolutely. Siva Roller manufactures complete ranges of offset, flexographic, gravure, lamination, slitting, nip, and guide rollers compatible with all major Indian and imported machines.

For flexible packaging plants, Siva Roller produces Nip Rollers, Laminating Rollers, Slitting Rollers, Silicone Rollers, PU Rollers, and adhesive-resistant Rubber Coated Rollers suitable for BOPP, PET, PE, foil, and multilayer laminates.

A superior roller reduces waste, prevents registration errors, improves ink/coating uniformity, and drastically lowers downtime. Buyers save on material loss, labour, replacement frequency, and machine adjustments—directly improving ROI.

Yes. The wrong roller compound often causes material buildup, surface pitting, or frequent cleaning. Siva Roller provides expert guidance to match the correct polymer to your chemicals, reducing maintenance and extending roller life.

Yes. Siva Roller customizes diameter, hardness, surface finish, length, and coating type based on your machine and application. Every roller is delivered to exact tolerances for perfect fitting and performance.

Printing, packaging, laminating, paper mills, textile processing, food packaging, label manufacturing, extrusion coating, corrugation, and industrial converting units widely use our rollers due to their reliability and durability.

Standard rollers dispatch quickly, while custom rollers typically take a short production cycle depending on size and complexity. Our West Bengal logistics partners ensure timely, safe delivery.

You can contact Siva Roller directly with your machine details, roller dimensions, and application. Our team provides a fast, transparent quote with technical recommendations to ensure you get the best-performance roller for your needs.