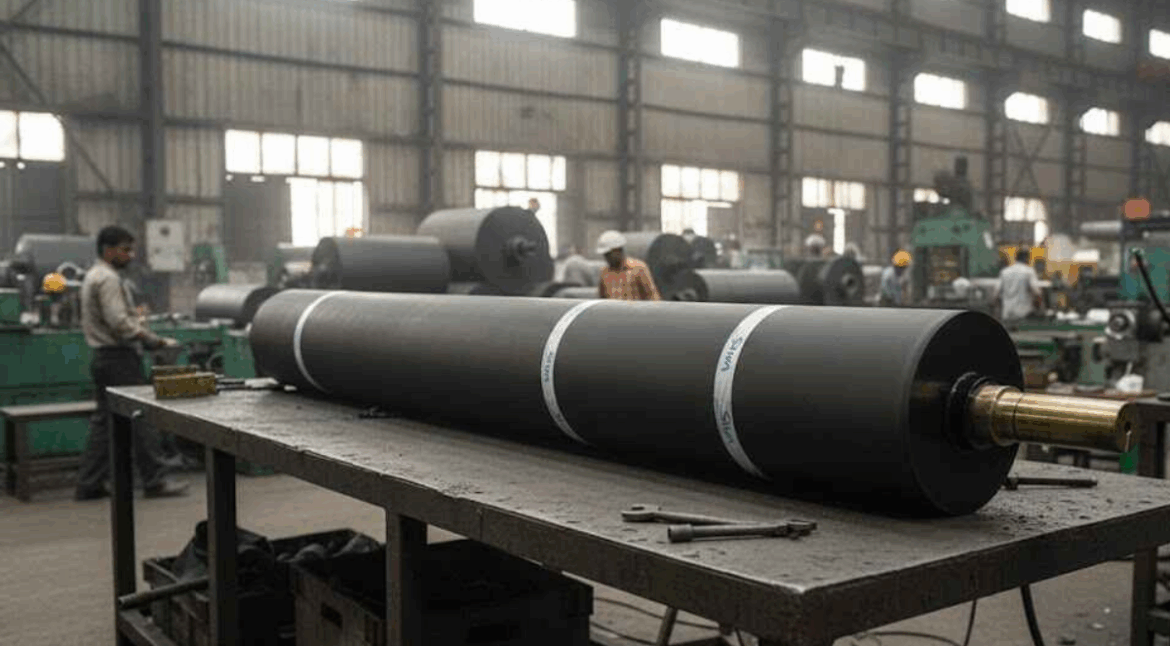

Choosing the Right Rubber Roller Manufacturer in Gujarat for Your Industry

The Unsung Hero of the Factory Floor: Why Your Roller Choice Matters

If you run a successful manufacturing unit in India, especially in a powerhouse state like Gujarat, you know that efficiency is everything. In the world of textiles, printing, packaging, and steel, there is one component that works silently but is critical for smooth, high-quality production: the Industrial Rubber Roller Gujarat.

These rollers are the heart of your machinery. They manage tension, spread materials evenly, apply pressure, and determine the finish quality of your final product. Yet, many businesses treat them as a simple commodity, only to realize their mistake when the production line grinds to a halt.

Gujarat, with its massive industrial ecosystem, has emerged as a premier hub for industrial components. While you can find a Rubber Roller Manufacturer in Gujarat in almost every state, the concentration of expertise, especially in cities like Ahmedabad, makes Gujarat a strategic starting point for your search. But how do you, the industrial buyer, cut through the noise and choose a partner, not just a seller?

This detailed guide is written to help industrial buyers like you solve that exact problem. We will focus on the practical factors, the hidden costs, and the service commitment that truly defines a world-class Rubber Roller Supplier in Gujarat.

The Hidden Costs of Compromise: Why Quality Pays Off

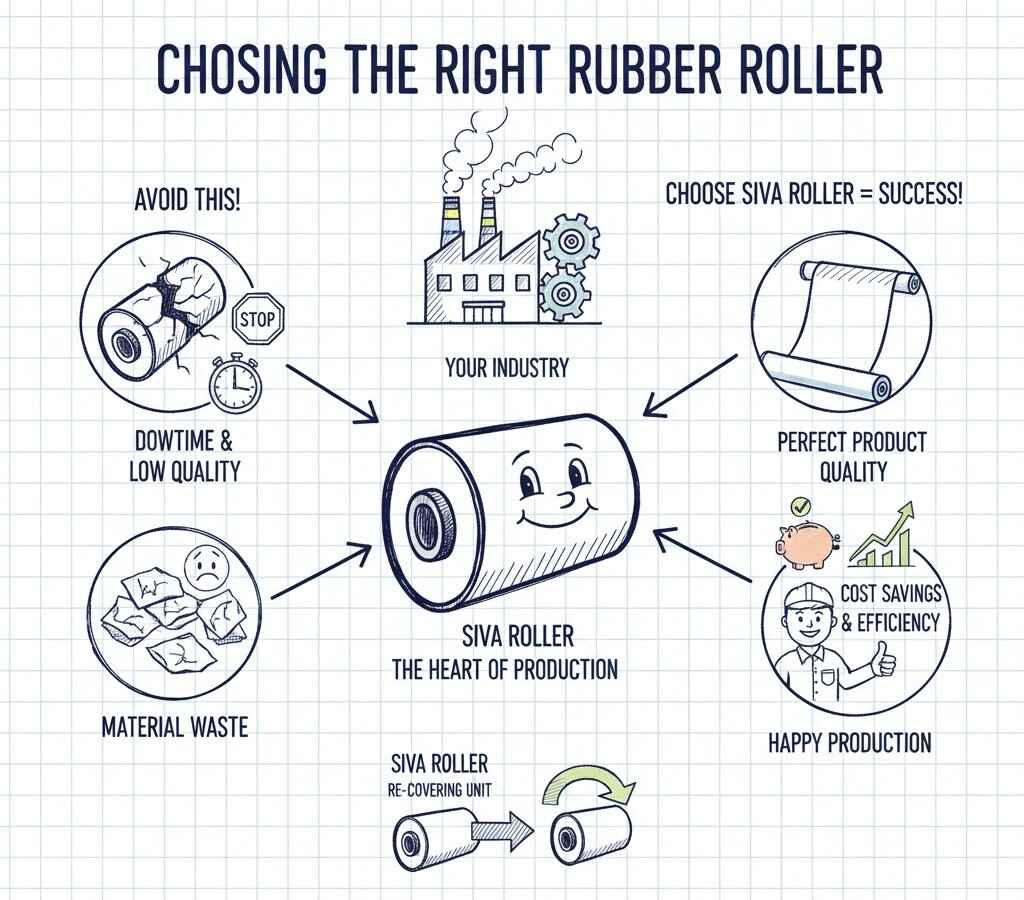

Every purchase decision in business is about balancing cost and risk. When buying industrial components, prioritizing the lowest price can often lead to the highest long-term costs. If you have ever faced unexpected machine downtime, material wastage, or customer rejection due to poor quality, the roller was likely the culprit.

Industrial buyers often search for a low price, but they are truly seeking reliability. Here are the common, costly problems that only a high-quality roller can prevent:

- Unexpected Downtime (The Biggest Killer): Imagine a production line running at full speed. Suddenly, a roller fails—perhaps the rubber separates from the core (called ‘dehulling’) or the surface wears out too quickly. This stops production instantly. The cost of lost production time, idle labor, and missed deadlines quickly overshadows any small saving made on the initial roller purchase.

- Inconsistent Product Quality (The Client Rejection Risk): In sectors like printing or lamination, the roller ensures precision. A low-quality roller might swell when exposed to solvents or lose its perfect cylindrical shape under heat and pressure. This results in streaking, poor ink transfer, or film misalignment, leading to entire batches of material being wasted.

- Frequent Maintenance and Replacement: If your maintenance team constantly has to grind or replace rollers, your operational costs remain high. A quality rubber compound, correctly engineered, has superior abrasion and chemical resistance, meaning it stays in service longer.

If you are currently experiencing any of these issues, you know your search is not for a generic component, but for a solution provider—a trusted partner among the numerous Industrial Roller Suppliers Vapi GIDC or anywhere else in the state.

The Three Essential Qualities of a Top Manufacturer

When you evaluate potential Industrial Rubber Roller Gujarat manufacturers, you must look beyond their product catalogue. Focus on these three core competencies:

Pillar 1: Material Science and Custom Compounding

A rubber roller is more than just rubber on a metal core; it’s a highly specialized polymer composite. The choice of compound (Natural Rubber, Nitrile, Neoprene, EPDM, Silicone, or Polyurethane) depends entirely on the operating environment:

- Heat and Steam: Rollers used in textile drying or high-temperature lamination need compounds that resist thermal degradation.

- Chemicals and Solvents: Printing or coating processes use aggressive solvents. The roller must be compounded specifically to resist swelling or softening when exposed to these chemicals.

- Wear and Abrasion: Heavy-duty applications like steel processing or paper mills require extremely high abrasion resistance.

A top manufacturer doesn’t just sell standard rollers; they offer custom compounding. They ask about your process, the solvents you use, and the temperature you operate at. This expertise is a hallmark of the best Rubber Roller Manufacturers in Ahmedabad.

Pillar 2: Precision Engineering and Dynamic Balancing

In modern high-speed machinery, a roller that is even slightly unbalanced can cause catastrophic vibration, leading to rapid bearing wear in the machine and poor product quality (like blurry printing).

Dynamic Balancing is a non-negotiable process. A quality manufacturer ensures that the roller is balanced to run smoothly even at very high RPMs. Furthermore, the core shaft and the rubber thickness must be concentric (perfectly centered). Precision grinding is essential to achieve the mirror-smooth finish and exact diameter required by your machine.

Pillar 3: Geographic Advantage and PAN India Service

While you are looking for a local solution in Gujarat, your business might serve customers across the country. The ideal manufacturer combines local expertise with a wide-reaching service network.

Ahmedabad, being a central hub for textiles, engineering, and packaging, is a key strategic location for manufacturing. Choosing a local Rubber Roller Manufacturers in Ahmedabad means easier communication, faster inspection, and quicker lead times. But importantly, this local expert must also be recognized as a leading Rubber Roller Manufacturer India, capable of servicing clients in Delhi, Mumbai, Kolkata, or Bangalore with the same level of commitment.

Addressing Gujarat Key Industrial Demands

Gujarat’s industrial landscape is diverse, requiring specialized rubber rollers for different sectors. A reliable manufacturer must demonstrate mastery in these specific areas:

For the Textile Industry (Surat and Beyond)

The textile sector, especially in and around Surat, involves high moisture, chemical dyes, and high temperatures. Rollers here face challenges from acidic or caustic solutions and constant immersion.

- Dyeing and Washing: Rollers need excellent chemical resistance and mechanical strength.

- Squeezing and Finishing: The roller must exert uniform pressure to ensure consistent moisture removal and fabric finish.

A true Textile Roller Manufacturer Surat will specialize in compounds like EPDM Rubber Roller for Textile Industry Surat. EPDM is particularly effective because it has outstanding resistance to water, steam, heat, and ozone, making it perfect for the harsh wet processing stages of textile manufacturing.

For Lamination and Converting Industries

The flexible packaging and lamination sector requires rollers that handle delicate films and strong adhesives. The challenge here is precision alignment and resistance to specialized chemicals used in bonding agents.

- Laminating Rolls: These rollers apply heat and pressure to bond layers (like plastic film and aluminum foil). They need rubber that maintains stability under heat without softening.

- Coating Rolls: Precision is paramount to apply a thin, consistent layer of adhesive or coating material.

For high-end lamination, the material of choice is often Silicone. If you are looking for stability at high temperatures and excellent release properties (so materials don’t stick), you should seek out a specialist in Silicone Rubber Roller for Lamination Gujarat. These rollers ensure perfect film alignment and minimal wastage, boosting your output quality.

For General Industrial and Packaging Applications

From conveyor systems in material handling to specialized printing presses, every factory needs robust general-purpose rollers. Whether you are in a GIDC estate near Vapi or a factory outside Ahmedabad, you need durable components. A great supplier acts as one of the best Industrial Roller Suppliers Vapi GIDC, providing solutions for every part of your operation.

Value Beyond Purchase – Industrial Roller Re-covering

A significant indicator of a manufacturer’s commitment is their ability to offer expert maintenance services, particularly Industrial Roller Re-covering Service Gujarat.

Think about the structure of your roller: it has a solid, precision-machined metal core, which is the expensive, engineered part. The rubber coating is the consumable component that wears out.

The Economic Advantage of Re-covering: Instead of buying a brand new roller every time the rubber surface is damaged or worn, re-covering allows the manufacturer to strip the old rubber, clean and inspect the core, and apply a fresh, new layer of rubber compound tailored to your exact needs.

- Cost Savings: Re-covering is often significantly cheaper than purchasing a new roller assembly.

- Speed: It is usually much faster than ordering a custom-built new core and covering.

- Sustainability: It’s an environmentally friendly practice that maximizes the lifespan of the engineered metal core.

When selecting a partner, always verify their re-covering capabilities. It shows they are interested in a long-term relationship based on maintenance and efficiency, not just a one-time sale.

Siva Roller: Setting the Gold Standard in Rubber Roller Manufacturing

In your search for the definitive Industrial Rubber Roller Gujarat solution, one name stands out for combining local Ahmedabad-based manufacturing excellence with a commitment to national service: Siva Roller.

Based right here in the industrial heartland of Gujarat, Siva Roller has built its reputation not on low prices, but on the precise quality and enduring performance of their products. They understand that a roller is an investment in your machinery’s efficiency.

Why choose Siva Roller as your dedicated Rubber Roller Supplier in Gujarat?

- Deep Local Understanding: Operating from Ahmedabad, they possess an intimate knowledge of the regional industrial demands, from the specialized needs of textile mills to the high-precision requirements of printing and packaging units. They are the trusted Rubber Roller Manufacturers in Ahmedabad for a reason.

- Unwavering Quality: Every roller produced is subject to rigorous quality checks, including dynamic balancing and hardness testing, ensuring consistent, reliable performance—from the largest industrial machine to the smallest printing press.

- Comprehensive Service: Siva Roller doesn’t just deliver a product; they deliver a service partnership. They excel in the necessary maintenance and quick turnaround for Industrial Roller Re-covering Service Gujarat, minimizing your costly downtime.

- National Reach: While their roots are strong in Gujarat, Siva Roller serves as a leading Rubber Roller Manufacturer India, supplying high-performance rollers across the country, ensuring that clients in every corner of the nation benefit from their Ahmedabad-engineered quality.

The Modern Industrial Buyer: How to Buy Rubber Roller Online Gujarat

The industrial procurement process is changing. In today’s digital world, you no longer need to rely solely on physical site visits to begin your order. Reputable manufacturers now provide excellent online information and procurement options.

If you need a quick quote, have a question about a specific compound (like EPDM or Silicone), or want to understand lead times, the ability to Buy Rubber Roller Online Gujarat makes the entire process faster and more transparent.

When dealing online, ensure the manufacturer’s platform provides:

- Clear Contact Channels: Easy access to technical sales support.

- Application Guidance: Resources to help you select the right compound for your machine.

- Service Quotes: Transparency regarding new roller manufacturing and re-covering costs.

Embracing this modern approach means you can quickly connect with a top Rubber Roller Supplier in Gujarat like Siva Roller, receive expert consultation without delay, and speed up the delivery of your critical

Your Next Step Towards Zero Downtime

Choosing an Industrial Rubber Roller Gujarat manufacturer is a strategic business decision. It is a choice between reliability and risk, between planned maintenance and unexpected breakdowns. The quality of your rollers directly impacts your bottom line, the lifespan of your machinery, and the satisfaction of your customers.

For manufacturers in Surat looking for the best EPDM Rubber Roller for Textile Industry Surat, or those in the lamination sector requiring precision Silicone Rubber Roller for Lamination Gujarat, or any industry needing a dependable Textile Roller Manufacturer Surat, the answer lies in partnering with proven expertise.

The commitment of a company like Siva Roller, rooted in Ahmedabad’s industrial strength and serving as a recognised Rubber Roller Manufacturer in India, ensures that you receive the highest standards of precision, durability, and service.

Don’t wait for the next production breakdown. Take control of your efficiency today. Reach out to Siva Roller, the trusted Rubber Roller Manufacturers in Ahmedabad, to discuss how their engineered solutions can secure your production line and maximize your output.

Contact Us

Emial : info@sivarollers.com

Phone Number :

FAQs

Selecting the right manufacturer directly affects your production speed, product quality, and machine lifespan. A well-engineered roller reduces downtime, prevents defects, and keeps your line running smoothly. A low-quality roller may save money initially but leads to heavy losses due to failures, rejections, and frequent replacements.

Textiles, printing, packaging, lamination, paper, steel, and converting industries use rubber rollers extensively. Cities like Surat, Ahmedabad, Vapi, and Vadodara rely on precision-engineered rollers to manage high-speed production.

Common issues include:

• Roller dehulling (rubber separating from metal)

• Excessive wear and swelling

• Poor ink or coating transfer

• Vibration due to imbalance

• Frequent maintenance and downtime

These failures quickly become more costly than the initial savings.

Check for material science expertise, custom rubber compounding, precision engineering, dynamic balancing, modern grinding technology, and strong after-sales support. Good manufacturers ask about your chemicals, temperature range, machine speed, and load before suggesting a solution.

Every industry uses different chemicals, heat levels, and pressures. Custom compounding ensures the roller performs well in your specific environment. For example, EPDM is ideal for textile wet processing, while Silicone is preferred for lamination and high-temperature work.

Yes. Even a slight imbalance can cause vibration, poor product finish, premature bearing damage, and machine wear. High-speed machines absolutely require dynamically balanced rollers for stable and smooth operation.

It depends on your operating conditions:

• EPDM – Textiles, dyeing, steam, water, wet processing

• Nitrile (NBR) – Oils, solvents, chemicals

• Neoprene – General industrial use with moderate chemical exposure

• Silicone – Lamination, high temperatures, non-stick properties

• Polyurethane (PU) – Heavy-duty and abrasion-resistant applications

A top manufacturer guides you through this selection carefully.

Look for fast delivery timelines, experienced service teams, and customers spread across India. A reliable Rubber Roller Manufacturer India will have clients in major cities like Delhi, Mumbai, Bengaluru, Kolkata, and Chennai, not only in Gujarat.

Gujarat has strong textile, printing, packaging, and engineering clusters, especially in Ahmedabad, Surat, Vapi, Ankleshwar, and Vadodara. This ecosystem encourages innovation, faster deliveries, and competitive production capabilities.

EPDM handles dyes, steam, heat, acids, alkalis, and constant moisture. It remains stable in harsh wet processing conditions, making it perfect for dyeing, washing, squeezing, and finishing applications in textile mills.

Silicone withstands high temperatures, offers excellent release properties, and ensures consistent pressure. It prevents sticking, maintains film alignment, and reduces wastage in laminators and coating machines.

The best suppliers offer complete solutions—new rollers, re-coating, grinding, dynamic balancing, inspection, and on-site support. This helps factories minimize downtime and extend roller life.

Absolutely. Re-covering helps you restore worn rollers at a fraction of the cost of buying new ones. A skilled manufacturer examines your old roller, re-engineers the material, and improves its lifespan.

This depends on usage hours, load, chemicals, and machine speed. In most industries, planned maintenance every 6–12 months helps avoid sudden breakdowns and maintains consistent product quality.

General-purpose rollers suit basic conveying or low-load work. Application-specific rollers are engineered for chemicals, heat, pressure, or abrasion. A reliable manufacturer guides you based on your process needs.

A good roller improves uniform tension, smooth feeding, precise pressure, better coating/ink transfer, stable machine speed, and reduced wastage. This directly boosts productivity and profitability.

Look for ISO certification, strict QC processes, use of imported polymers, precision engineering machinery, and documented testing practices. This ensures consistency in every batch.

Yes. Roller hardness is crucial for pressure, grip, and product finish. A good manufacturer provides hardness options from soft (20 Shore A) to very hard (100 Shore A), depending on your application

Check whether they offer site visits, re-balancing, quick replacement services, technical consultation, and emergency support during breakdowns.

WhatsApp us