Trusted Stainless Steel Roller Manufacturer in India

The operational efficiency of continuous processing lines—from high-speed printing and packaging to precision paper manufacturing and rigorous textile treatment—hinges on a few critical, often overlooked, components: industrial rollers. When dealing with high temperatures, aggressive chemicals, or demanding hygiene standards, only stainless steel delivers the necessary performance envelope.

For procurement managers and production heads across India, the search is not merely for a supplier, but for a truly Trusted Stainless Steel Roller Manufacturer in India—a partner whose commitment to engineering precision directly translates into sustained operational uptime and superior product quality.

Siva Rollers, a leading name in industrial roller technology, understands that a roller is not just a tube and a shaft. It is a calculated piece of engineering that must uphold the integrity of your entire production process. We build reliability, not just components.

The True Cost of Compromise: Why Standard Rollers Fail Critical Applications

In the relentless pursuit of cost reduction, many procurement teams encounter the pitfalls of low-grade or poorly fabricated industrial rollers. In critical environments, this compromise leads to devastating ripple effects:

- Corrosion and Contamination: In food-grade applications, pharmaceutical production, or textile dyeing processes, standard steel or poorly treated rollers introduce rust, pitting, and contamination, leading to costly batch rejections and regulatory non-compliance.

- Premature Wear and Downtime: Inferior rollers suffer rapid material degradation, leading to frequent replacements, unscheduled stops, and a collapse in overall equipment effectiveness (OEE).

- Inconsistent Product Quality: Poor concentricity or dynamic balancing in a standard roller introduces vibration, stretching, and marking on substrates, immediately degrading the quality of paper, film, or fabric.

The solution lies in specialized metallurgy, superior fabrication, and unwavering quality control—the hallmarks of an expert Stainless Steel Roller Manufacturer in India.

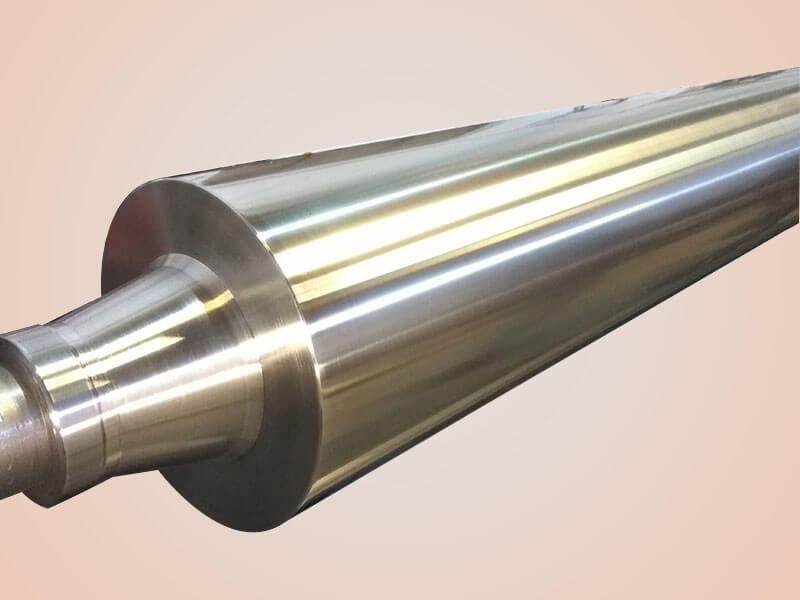

The Core of Siva Stainless Steel Roller Advantage

Siva Rollers has established its reputation as a preferred Industrial Roller Supplier by addressing these core pain points through rigorous process control, not just raw material use. Our approach to manufacturing a Stainless Steel Roller is defined by three pillars: material science, thermal mastery, and dynamic precision.

1.Material Selection: Beyond Standard Grade

While stainless steel is the foundation, selecting the appropriate alloy—be it SS 304, 316, or specialized variants—is crucial for longevity in specific corrosive environments.

- SS 304: Ideal for general industrial use, offering excellent corrosion resistance and hygiene standards in packaging and food-related handling.

- SS 316: Mandated for harsh chemical exposure, such as aggressive cleaning agents in paper mills or strong dyes in textile finishing, due to its enhanced resistance to pitting and localized corrosion.

We ensure that every Heavy Duty Stainless Steel Rollers fabricated meets the precise material specification required for your operational environment, certifying the composition and traceability of the steel used.

2. Specialized Thermal Control: The Heat Transfer Roller

In coating, lamination, and drying processes, the roller is not just a conveyance mechanism—it is a heat exchanger. Inefficient heat transfer rollers result in uneven curing, energy waste, and product defects.

Siva Rollers designs and manufactures specialized Heat Transfer Roller units engineered for rapid, uniform heat distribution across the entire working width.

- Uniform Internal Flow: Optimized internal baffling systems ensure minimal temperature variation (Delta T) between the inlet and outlet, guaranteeing consistent process temperatures across the web.

- Precision Surface Finish: The roller surface is finished to the exact roughness average (Ra) required to maximize thermal conductivity at the point of contact with the substrate. This precision makes us the authoritative SS Roller Manufacturer India for demanding thermal applications.

3. Precision Guidance: The Stainless Steel Guide Roller

Even minute deviations in web alignment can ruin an expensive roll of material. Precision alignment starts and ends with the Stainless Steel Guide Roller. These passive rollers demand the highest level of concentricity and dynamic balance to ensure smooth, low-friction passage of materials.

Our guide rollers feature:

- Near-Zero Runout: Machining tolerances are held to micrometer levels to eliminate radial and axial runout, crucial for maintaining tension control and preventing web wandering in high-speed applications.

- Low Inertia Design: Optimized wall thickness reduces rotational inertia, allowing the roller to react instantaneously to changes in web speed and tension without slippage or overshooting.

This focus on dynamic precision allows industrial partners to Buy Stainless Steel Roller components that enhance, rather than limit, their machine speed.

Problem-Solution Focus Across Key Industries

Siva Rollers partners with diverse industrial sectors, delivering targeted roller solutions that solve chronic production challenges:

1. Paper and Pulp Manufacturing

The Problem: High moisture content, acidic pulps, and continuous abrasion lead to rapid bearing failure, surface erosion, and frequent regrinding of press and felt rollers.

The Siva Solution: Our stainless steel press and felt rollers are designed with heavy-duty journals and specialized corrosion-resistant surface treatments. This significantly extends the time between maintenance cycles, reducing the substantial costs associated with downtime in a high-throughput paper mill. This reliability cements our role as a trusted Steel Roller Manufacturer in india.

2. Textile Processing and Finishing

The Problem: Hot, chemically aggressive dyeing and mercerizing baths demand rollers that resist chemical attack while maintaining perfect alignment to prevent fabric skewing or creasing.

The Siva Solution: We supply SS 316 rollers with high-polish or specialized grooved surfaces to ensure optimal liquid carryover and prevent fibre adhesion. Our rollers maintain structural integrity in caustic environments, offering a longer lifespan and maintaining consistent fabric quality under extreme conditions.

3. Coating and Lamination Lines

The Problem: The transfer of precise amounts of adhesive or coating materials requires doctor-blade compatibility and absolute surface uniformity, with zero risk of roll distortion under pressure or heat.

The Siva Solution: As a proven Industrial Roller Supplier, we provide mirror-finish stainless steel rollers that are stress-relieved and internally cooled for thermal stability. This guarantees that your coating weight remains uniform from edge to edge, maximizing material efficiency and minimizing expensive rework.

Buy Stainless Steel Rollers from India Trusted OEM Brand

Siva Rollers has delivered thousands of Stainless Steel Rollers across India and global markets, supporting continuous production environments with high uptime performance.

If you are planning a new plant setup, capacity expansion, machine rebuild, or seeking a replacement for worn-out rollers—Siva Rollers offers the ideal solution.

A Partnership Built on Certification and Traceability

When you choose to Buy Stainless Steel Roller components from Siva Rollers, you are investing in total supply chain transparency. We provide comprehensive documentation for every roller we manufacture:

- Material Test Certificates (MTCs): Full traceability of the stainless steel grade, ensuring compliance with specified chemical and mechanical properties.

- Dynamic Balancing Reports: Certification that the roller meets the stringent ISO balancing grade required for the intended operating speed, eliminating the risk of vibration and instability.

- Dimensional Inspection Reports: Verification of critical tolerances, including parallelism, runout, and overall dimensional accuracy.

Our systematic approach to quality control is why major players across the nation recognize us as the definitive Stainless Steel Roller Manufacturer in India. We eliminate the uncertainty from your procurement process.

Ready to Increase Production Efficiency? Request a Quote

The decision to source critical industrial components should not be based solely on price. It must be based on proven reliability, engineering rigor, and the assurance of working with a high-authority OEM partner.

If your operational mandate is to reduce downtime, enhance product quality, and secure a long-term, high-performance solution, the time for incremental fixes is over.

Siva Rollers – Trusted Stainless Steel Roller Manufacturer in India

High Precision | High Durability | OEM Grade Engineering

- Call / WhatsApp: +91 75070 10009

• Email: info@sivarollers.com

• Website: www.sivarollers.com

Request a custom quotation or schedule a technical discussion today.

Siva Rollers is the trusted manufacturing benchmark for stainless steel components in India.

Stop the cycle of premature replacement and poor performance. Contact our engineering team today to discuss your specific application challenges and discover how our precision-engineered Heavy Duty Stainless Steel Rollers can transform your production line efficiency.

Choose Siva Rollers. Choose Uncompromising Performance. Contact us now to partner with the most reliable Steel Roller Manufacturer in india

FAQs

Siva Rollers is recognized for precision engineering, certified raw materials, and advanced manufacturing technology. Every stainless steel roller undergoes strict quality inspection, dynamic balancing, and MTC-based traceability to ensure high durability, performance stability, and maximum uptime in industrial applications.

Stainless Steel Rollers are widely used across printing & packaging, paper & pulp, textile dyeing and finishing, coating & lamination, food handling, pharmaceuticals, chemical processing, and insulation manufacturing—anywhere hygiene, corrosion resistance, or high-temperature performance are critical.

Most production environments use SS 304 or SS 316 depending on operating conditions.

SS 304 is ideal for general industrial use and food-handling systems.

SS 316 offers superior corrosion resistance in chemical, dyeing, and acidic environments. Siva Rollers supplies both grades along with specialized SS variants based on technical requirements.

Heat Transfer Rollers are engineered to ensure uniform heat distribution across substrates during drying, lamination, or coating. They prevent uneven curing, material distortion, and product rejection—eliminating major production losses in high-speed processing lines.

Guide rollers maintain precise web alignment and eliminate tracking issues that cause creasing, waviness, or substrate damage. With micrometer-level runout control and low-inertia construction, they support smooth high-speed movement.

Stainless steel resists corrosion, surface pitting, chemical attack, and wear. This durability significantly extends roller lifespan, reduces replacement frequency, and improves Overall Equipment Effectiveness (OEE).

Yes. Siva Rollers provides Material Test Certificates (MTCs), dynamic balancing reports, and dimensional inspection reports ensuring accuracy, material traceability, and performance compliance.

Absolutely. We specialize in OEM-grade custom engineering including custom load capacities, finishes, lengths, diameters, grooving patterns, and internal cooling systems based on production line needs.

Yes, we supply stainless steel rollers to global customers and export to multiple countries, supporting both new installations and machine modernization projects.

You can contact our engineering team via Call/WhatsApp, email, or website. Share your process requirements and we will provide a custom technical solution and pricing proposal tailored to your application.