Leading Rubber Roller Manufacturer for Printing & Packaging Machines

If you are searching for a reliable Rubber Roller Manufacturer for printing presses or high-performance packaging machinery, precision and durability matter more than anything else. A roller failure can shut down production, damage material, increase scrap cost, and delay delivery schedules.

That’s why industrial procurement managers and production heads prefer choosing a trusted Industrial Rubber Roller Manufacturer who delivers engineering accuracy, custom material science, and consistent long-term performance.

Siva Rollers is a leading name in the industrial roller industry, delivering advanced, precision-engineered rollers to printing and packaging units across India. From custom compound development to expert support, we ensure your machines run faster, smoother, and without unexpected downtime.

If you are an industrial buyer, procurement manager, or production head searching for a long-term solution to your roller problems, you’ve come to the right place. We are diving deep into what defines a world-class Industrial Rubber Roller Manufacturer and introducing you to the experts at Siva Roller, dedicated to ensuring your machines run flawlessly across India.

Why Choosing the Right Rubber Roller Manufacturer Matters

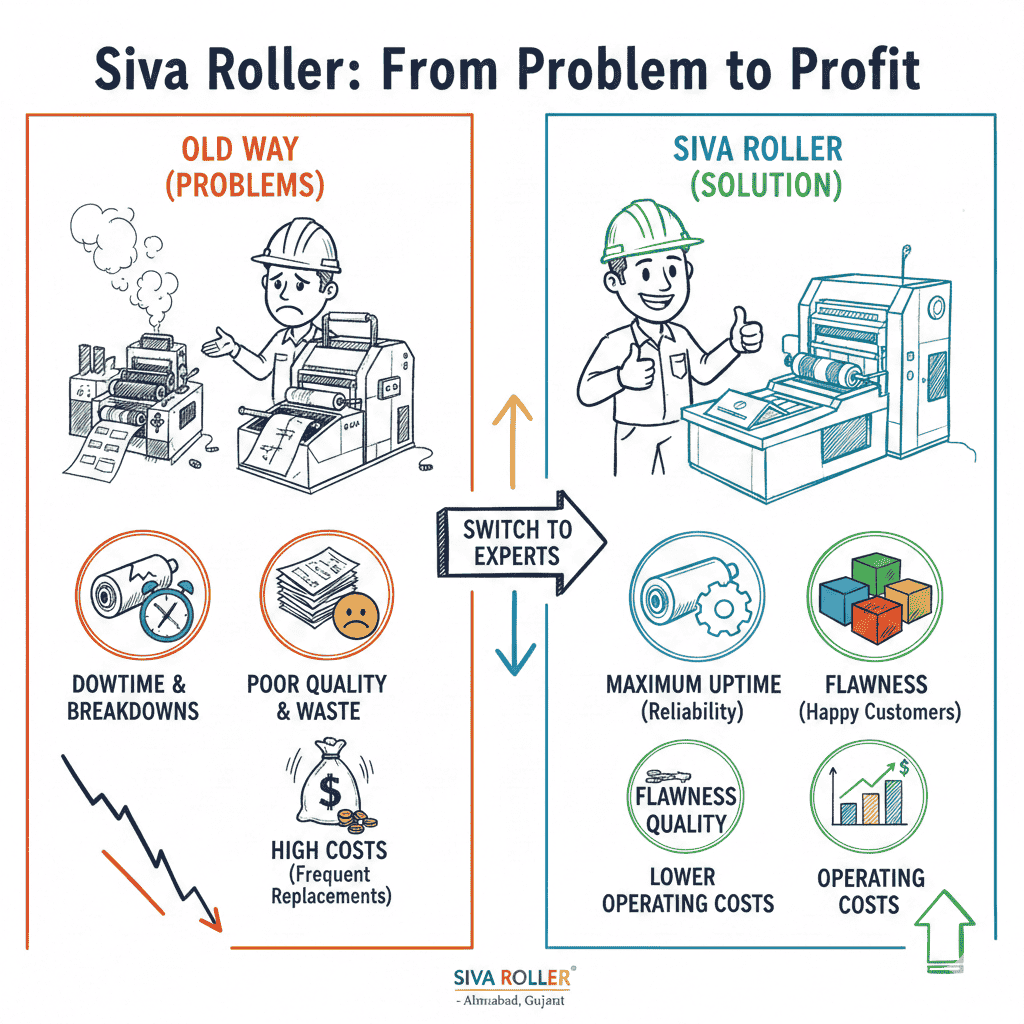

A large number of industrial plants face recurring failures because of low-grade rollers purchased only on price. Cheap rollers ultimately cost more due to frequent repairs and machine stoppages. The real value is not in the purchase cost, but the total operational cost of the roller.

Common Problems Caused by Poor-Quality Rubber Rollers

Sudden breakdowns due to cracking, swelling, hardening or delamination

Inconsistent printing quality (ghosting, streaking, poor registration)

Frequent re-grinding or replacement

Loss of grip and poor material handling in packaging machines

Wrong compound selection for inks, solvents, and heat

These failures occur when suppliers focus on bulk production instead of engineering expertise.

Common Problems Caused by Poor-Quality Rubber Rollers

For many businesses, the purchase decision for rubber rollers is often driven by one factor: the lowest price. This approach, however, almost always leads to a false economy. The real cost of a roller isn’t the purchase price; it’s the total cost of ownership, which is overwhelmingly affected by its lifespan and reliability.

Industrial buyers frequently face frustrating issues that cheap, mass-produced rollers cannot solve:

- Unexpected Downtime: A roller that prematurely cracks, swells, or loses its grip requires emergency replacement. This unscheduled downtime can derail monthly targets and lead to huge financial penalties.

- Inconsistent Product Quality: In printing, a poor-quality inking or dampening roller leads to defects like streaking, ghosting, or poor colour registration. In packaging, this might manifest as uneven lamination, weak seals, or faulty conveying. Every rejected product due to poor finish is a direct hit to your bottom line.

- Rapid Deterioration: High-speed machines generate immense heat, pressure, and exposure to aggressive solvents and inks. Rollers must be chemically and thermally resilient. If the rubber compound is generic or low-grade, it hardens, glazes, or begins to peel within months, forcing costly, frequent regrinding or replacement.

- The Wrong Compound for the Job: Your process is unique—whether you’re dealing with high-UV flexo inks, aggressive solvents in lamination, or heavy loads on a conveyor belt. Using an off-the-shelf roller that is “close enough” will never deliver optimal performance.

These are not just technical failures; they are commercial failures caused by choosing a manufacturer who is just a vendor, not an expert partner.

What Makes Siva Rollers a Trusted Industrial Rubber Roller Manufacturer

When searching for a top-tier Rubber Roller Manufacturer, you must look beyond basic manufacturing capability. A truly superior manufacturer acts as a consultant, helping you maximize the efficiency and lifespan of your expensive machinery.

Here is a checklist of the qualities that separate a global leader from the average supplier:

Technical Expertise + Custom Engineering

Every application is unique—flexo printing, rotogravure, offset, HD lamination, film conveying, sealing, or coating. We engineer rollers based on: line speed, temperature range, ink / film type, chemical exposure, and required Shore hardness.

Advanced Material Science

We develop high-performance compounds including Nitrile (NBR), EPDM, Silicone, Neoprene, Natural Rubber, and Polyurethane (PU) ensuring superior abrasion resistance, thermal stability, and extended roller life.

Precision Manufacturing & Quality Control

Every roller undergoes testing for dimensional accuracy, concentricity, balance, and surface finish to ensure consistent performance across batches.

Siva Roller: Your Trusted Industrial Rubber Roller Manufacturer in India

For decades, the name Siva Roller has been synonymous with precision, reliability, and engineering excellence in the roller industry. As a dedicated Rubber Roller Manufacturer, we have built our reputation on solving the most complex challenges faced by the printing and packaging sectors across the continent.

Strategically Located in Ahmedabad, Gujarat

While our reach extends nationwide, our advanced manufacturing facility is strategically located in Ahmedabad, Gujarat. This central location provides significant logistical advantages, allowing us to serve as a fast and reliable Rubber Roller Supplier to industrial hubs across Gujarat, Maharashtra, Delhi NCR, and the entire South of India.

Our location means:

- Faster Delivery Times: Reduced logistics costs and quicker turnaround compared to relying solely on imported or far-flung suppliers.

- Local Expertise: We understand the unique environmental challenges in India, such as extreme temperature fluctuations and high humidity, which can degrade standard rubber compounds. Our formulations are specifically designed to thrive in the demanding Indian climate, ensuring superior longevity and performance.

Industries & Applications We Serve

Printing Press Rollers

Inking Rollers

Dampening Rollers

Transfer Rollers

Gravure Applicator Rollers

High-speed flexo & rotogravure rollers

Packaging & Converting Rollers

Laminating Rollers

Nip / Squeeze Rollers

Expander & Bow Rollers

Coating / Sealing Machine Rollers

Web Guiding Rollers

The Siva Roller Advantage: Moving Beyond the Standard Supplier Mindset

We believe that being a great Rubber Roller Supplier requires adopting a partnership mindset. Our process is designed to eliminate the guesswork and recurring failures that plague the industry.

Maximum Uptime Through Customization

We do not believe in a ‘one-size-fits-all’ solution. Our first step is a detailed analysis of your operational requirements. This personalized approach means we engineer the precise rubber compound, Shore hardness, and surface finish needed for your specific machine, leading to rollers that last significantly longer and require less maintenance. This dedication to tailored quality is what makes us the preferred Industrial Rubber Roller Manufacturer for clients prioritizing production stability.

Guaranteed Quality Control

The key to our consistency is our state-of-the-art manufacturing infrastructure. Every roller we produce undergoes rigorous quality checks:

- Dimensional Accuracy: Ensuring the roller’s diameter and length meet the tightest specifications.

- Concentricity: Guaranteeing the roller runs perfectly true without wobble, which is crucial for high-speed operation and print quality.

- Surface Finish: Verifying the smoothness and profile of the surface, which directly impacts coating and ink transfer efficiency.

This meticulous quality control process ensures that when you choose Siva Roller, you are investing in predictability and peace of mind.

Re-Rubberizing & Roller Refurbishment Services

Why scrap an expensive metal core when only the rubber cover is worn? Our specialized re-rubberizing and grinding facility can strip the old compound, inspect the core for damage, and bond a brand-new, high-performance rubber cover. This process significantly saves you money compared to buying new cores and contributes to sustainable, efficient operations. It’s an essential service offered by a responsible Rubber Roller Manufacturer in India.

Your Partner for Growth: Siva Roller Commitment to India Industries

The industrial landscape in India is expanding rapidly, demanding higher production speeds and uncompromised quality standards. To meet this demand, you need a Rubber Roller Manufacturer that is equally committed to innovation and reliability.

We serve clients not just in Gujarat, but across the nation—from the textile mills in Coimbatore to the printing houses in Delhi and the major packaging manufacturers in Mumbai and Kolkata. Our nationwide supply chain ensures that quality, precision-engineered rollers are always within reach, regardless of where your plant is located.

Choosing Siva Roller means choosing:

- Zero Compromise: Rollers built with premium materials for maximum chemical and temperature resistance.

- Expert Advice: Direct access to technical experts who can troubleshoot and recommend the perfect roller for any new or existing machine.

- Local Reliability: Fast, dependable service from a dedicated Industrial Rubber Roller Manufacturer located right here in Ahmedabad, Gujarat, serving the whole of India.

Don’t let frequent roller failures define your production efficiency. It’s time to switch from being a customer who buys rollers to being a partner who owns a roller solution.

Talk to Rubber Roller Experts – Request Free Technical Consultation

Your search for the Best Rubber Roller Manufacturer ends here. The problems of frequent downtime, wasted material, and inconsistent quality are solvable—but only by partnering with a manufacturer that prioritizes engineering precision and application knowledge over basic cost.

Siva Roller is dedicated to serving as your definitive Rubber Roller Supplier and expert consultant, providing precision-engineered rollers that keep your printing presses and packaging lines running smoothly, quickly, and profitably. We are here to support your growth with high-quality, long-lasting rollers designed for the specific demands of the Indian industrial environment.

Ready to eliminate unexpected machine downtime and secure truly reliable components for your production line? Talk to our experts today and find out how a custom-engineered roller solution from Siva Roller can transform your operational efficiency.

Connect with Siva Roller Experts We specialise in tailoring the perfect rubber compound and roller finish for your specific machinery and operational challenges. Do not settle for off-the-shelf solutions.

Click here to discuss your printing or packaging roller requirements.

Frequently Asked Questions – Rubber Roller Manufacturer

Look for a manufacturer with deep application knowledge, custom rubber compound development, advanced manufacturing accuracy, and strong after-sales service. A reliable partner should help improve machine uptime, product quality, and roller lifespan, rather than just offer low purchase prices.

Premature roller failure often happens due to incorrect rubber compound selection, exposure to aggressive chemicals, high temperatures, or poor-quality bonding and grinding. Cheap rollers may crack, swell, harden, or lose grip, resulting in downtime and poor print or packaging output.

Every roller goes through strict precision checks, including hardness testing, concentricity, surface finish inspection, and dimensional accuracy. Customized compounds such as Nitrile, EPDM, Silicone, and Polyurethane are engineered to withstand chemical exposure, heat, and high-speed production demands.

Yes, Siva Roller specializes in customized solutions. Instead of offering generic rollers, we engineer the right compound, Shore hardness, and surface finish based on your ink/film type, line speed, temperature range, and application type.

Absolutely. Siva Roller provides re-rubberizing, grinding, and balancing services to restore old rollers to like-new performance. This significantly reduces replacement costs and extends machine asset life.

We manufacture and supply high-performance rollers for printing presses, packaging and lamination machines, coating lines, slitting machines, sealing units, and converting equipment across India.

We supply inking rollers, dampening rollers, transfer rollers, gravure applicator rollers, and specialized high-speed rollers used in flexo, offset, and rotogravure printing presses.

Custom compounds provide better chemical resistance, heat stability, abrasion strength, improved print quality, and longer service life. This reduces maintenance frequency and prevents unexpected downtime.

Yes, we ship nationwide including Ahmedabad, Mumbai, Delhi NCR, Pune, Chennai, Hyderabad, Bangalore, and Kolkata through a strong logistics network for faster delivery and reduced downtime.

You can contact our technical specialists to discuss requirements, compound selection, or roller failures. We provide expert guidance and quotations for new rollers and refurbishment services.