How Rubber-Coated Rollers Improve Paper Coating & Calendering Machines

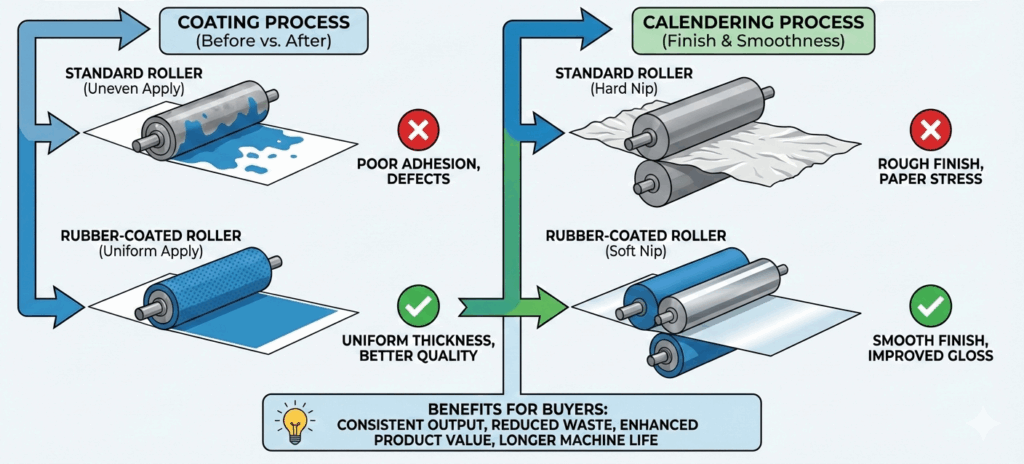

As mechanical engineers working deep inside the pulp and paper ecosystem, we’ve learned one simple truth the hard way: paper quality is rarely limited by chemistry alone. More often, it is limited by contact. The moment wet paper meets a roller—during coating, pressing, or calendering—physics takes control. Pressure distribution, surface energy, elasticity, and wear behavior decide whether a machine produces premium paper or kilometers of downgraded stock.

That is where rubber coated rollers quietly do the heavy lifting.

We at Siva Rollers have spent years engineering industrial rubber rollers specifically for paper mills, where consistency is not a preference but a survival requirement. This article unpacks how rubber-coated rollers improve coating and calendering performance, why compound choice matters, and what paper manufacturers should look for when selecting a roller partner—not just a supplier.

The Mechanical Reality Inside Paper Coating & Calendering Lines

Paper coating and calendering machines operate in a narrow mechanical comfort zone. Loads are high, speeds are relentless, and tolerances are unforgiving. Any imbalance—microns of uneven pressure, a hint of surface glazing, or slight hardness drift—shows up immediately as:

- Coating streaks

- Gloss variation

- Thickness inconsistency

- Premature roll wear

- Sheet breaks and downtime

Unlike steel rollers, rubber coated rollers introduce controlled compliance. That elasticity is not softness for comfort—it is mechanical intelligence.

Rubber deforms just enough to equalize pressure across the sheet width. That one property alone explains why rubber dominates coating and calendering sections across modern paper mills.

Why Rubber-Coated Rollers Outperform Metal Rollers in Paper Mills

Uniform Pressure Distribution

In coating machines, the coating color must be applied evenly at high speed. Steel rollers, even when precision-ground, cannot compensate for sheet caliper variation. Rubber can.

Rubber-coated coating work rollers conform microscopically to paper surface irregularities, ensuring:

- Consistent coating weight

- Reduced edge buildup

- Improved sheet appearance

This pressure uniformity is especially critical in blade coating and film press applications.

Controlled Nip Behavior in Calendering

Calendering is not just about smoothness—it’s about controlled densification. Calender rollers with rubber coatings allow paper fibers to compress gradually rather than brutally.

The result is a better balance of:

- Smoothness

- Bulk retention

- Printability

Rubber coatings act like mechanical shock absorbers, reducing fiber damage while improving surface finish.

The Role of Rubber Compound Selection in Performance

Not all rubber is created equal. In paper mill rollers, compound selection influences heat resistance, chemical stability, wear life, and surface interaction with coatings.

Below is a simplified comparison of commonly used rubber compounds in paper mill rollers:

Rubber Compound | Typical Application Behavior | Why It’s Used |

Natural Rubber (NR) | High elasticity, excellent resilience | Ideal for calendering where pressure recovery matters |

Nitrile Rubber (NBR) | Good oil and chemical resistance | Suitable for coating lines using solvent-based chemicals |

EPDM | Heat and moisture resistant | Performs well in wet-end and high-temperature zones |

Polyurethane (PU) | High abrasion resistance | Used where long wear life is critical |

At Siva Rollers manufacturing, we do not push a “one-compound-fits-all” mindset. Every coating and calendering application behaves differently. Rubber must be engineered to the process, not the catalog.

Surface Finish: The Hidden Variable in Coating Quality

Paper manufacturers often focus on hardness numbers and overlook surface finish. That’s a costly mistake.

A rubber-coated roller’s surface texture controls:

- Coating transfer efficiency

- Release characteristics

- Micro-slip behavior

Too smooth, and the coating can skid. Too rough, and it traps coating material, causing streaking.

We at Siva Rollers engineer surface finishes specifically for coating chemistry and machine speed. That tuning is one reason our custom rubber-coated rollers for the paper industry deliver consistent results across long production runs.

Rubber-Coated Rollers and Machine Stability

High-speed paper machines amplify every mechanical weakness. Vibrations, resonance, and nip instability show up faster as speeds increase.

Rubber coatings dampen vibration naturally. This damping effect:

- Reduces machine noise

- Improves web stability

- Extends bearing and journal life

Over time, this translates into fewer unscheduled shutdowns and lower maintenance costs—benefits that matter far beyond the roller itself.

Where Rubber-Coated Rollers Make the Biggest Impact

Coating Sections

In coating machines, rubber coated rollers ensure:

- Uniform film thickness

- Stable coating transfer

- Reduced coating waste

They act as precision interfaces between chemistry and mechanics.

Calender Stacks

In calendering, rubber-coated calender rollers:

- Improve gloss without crushing fiber structure

- Maintain sheet integrity at high nip loads

- Deliver repeatable surface properties

This balance is critical for printing and packaging grades where appearance sells the product.

Longevity, Recoating, and Lifecycle Economics

A roller should not be viewed as a consumable—it is a system component with a lifecycle.

High-quality industrial rubber rollers can be stripped and recoated multiple times without compromising performance, provided the core is properly engineered and maintained.

At Siva Rollers, our focus is not just on first installation. We design rollers for:

- Predictable wear behavior

- Stable hardness over time

- Efficient recoating cycles

That lifecycle approach lowers total cost of ownership, which is where smart paper mills make their real savings.

Why Paper Mills Choose Siva Rollers

Our reputation in Siva Rollers manufacturing has been built on three principles:

- Application-driven design, not generic templates

- Consistent quality across production batches

- Deep technical understanding of paper mill environments

From coating work rollers to calender rollers, our rubber-coated solutions are engineered to perform under real mill conditions—heat, load, speed, and chemical exposure included.

Final Perspective from the Machine Floor

Rubber-coated rollers rarely get credit when a paper machine runs flawlessly. That silence is their success. When coating looks perfect and calendering delivers uniform gloss shift after shift, it means the roller system is doing exactly what physics demands.

In modern paper manufacturing, rubber coated rollers are not optional enhancements. They are core mechanical tools that decide quality, efficiency, and profitability.

At Siva Rollers, we continue refining these tools—compound by compound, micron by micron—so paper mills can push performance without pushing risk.

Paper may look simple when it leaves the reel. Inside the machine, it is anything but.

CONTACT US

FAQs

Rubber coated rollers are used in paper mills to control pressure, surface contact, and material transfer during coating, pressing, and calendering processes. Their elastic surface ensures uniform load distribution across the paper width, improving coating consistency, sheet smoothness, and machine stability.

Rubber coated rollers improve paper coating quality by providing controlled deformation at the nip point. This allows the roller to compensate for paper thickness variations, ensuring even coating weight, reduced streaking, and better surface finish at high machine speeds.

Rubber coated rollers are preferred in calendering machines because they deliver gradual and uniform compression. Unlike steel rollers, rubber coatings reduce fiber damage, maintain bulk, and improve gloss consistency, which is critical for printability and surface aesthetics.

Rubber coating is commonly used on:

- Coating work rollers

- Calender rollers

- Press section rollers

- Spreader and guide rollers

These paper mill rollers rely on rubber coatings to manage pressure, vibration, and surface interaction with the paper web.

Rubber hardness determines how much the roller surface deforms under load. Softer rubber improves pressure uniformity, while harder rubber offers better wear resistance. Selecting the correct hardness is essential to balance coating control, calendering smoothness, and roller lifespan.

Commonly used compounds include natural rubber, EPDM, nitrile rubber, and polyurethane. The best compound depends on operating temperature, chemical exposure, machine speed, and desired surface behavior. Custom compound selection ensures optimal performance in coating and calendering applications.

The service life of rubber coated rollers depends on operating conditions, compound selection, and maintenance practices. High-quality industrial rubber rollers can operate reliably for extended periods and can be recoated multiple times, reducing total lifecycle cost.

Yes. Most rubber coated rollers used in paper mills can be stripped and recoated without replacing the core. Recoating restores performance, extends roller life, and significantly lowers replacement costs when done by an experienced manufacturer.

Common signs include uneven coating, gloss variation, vibration, sheet tracking issues, and increased downtime. These symptoms often indicate surface wear, hardness drift, or loss of elasticity in the rubber coating.

Rubber coatings naturally absorb and dampen vibration. This reduces resonance at high speeds, stabilizes the paper web, lowers noise levels, and protects bearings and machine components from premature wear.

Choose a manufacturer with proven experience in paper mill rollers, in-house rubber compounding, precision grinding capabilities, and application-specific engineering support. A reliable manufacturer offers custom solutions, consistent quality, and long-term technical support.

Siva Rollers is recognized for manufacturing high-performance custom rubber-coated rollers for the paper industry. We combine application expertise, controlled manufacturing processes, and deep understanding of coating and calendering machines to deliver reliable, long-lasting roller solutions.

Yes. By stabilizing nip pressure, improving coating transfer, and reducing vibration, rubber coated rollers enhance production consistency, reduce waste, minimize downtime, and improve overall machine efficiency.

Rubber coated rollers are specifically engineered for high-speed operations. Their controlled elasticity and vibration damping properties make them ideal for modern paper machines operating at elevated speeds and loads.