How Industrial Expander Bow Rollers Improve Web Control & Process Stability

In the high-speed world of industrial manufacturing—whether you are dealing with paper, plastic film, textile, or non-woven materials—the “web” is the lifeline of your production. Any disruption in web tension, alignment, or surface smoothness can lead to catastrophic material waste, machine downtime, and loss of profit.

One of the most critical yet often misunderstood components in achieving a flawless production run is the Expander bow rollers. Also known by industry professionals as banana rollers or spreader rollers, these specialized tools are the unsung heroes of web handling equipment.

In this guide, we will dive deep into how these rollers work, why they are essential for process stability, and why Siva Rollers is recognized as the best Expander Bow Rollers Manufacturer & Supplier in India.

What Are Expander Bow Rollers?

At its core, an expander bow roller is a roller designed with a pre-determined curve or “bow.” Unlike standard straight rollers that simply support the web, bowed rollers are engineered to apply a precise amount of outward tension from the center of the material to its edges.

This outward stretching action is what provides the “expanding” effect. Whether you are running a thin 10-micron film or a heavy-duty textile, these rollers ensure the material remains flat, taut, and centered as it moves through various stages like slitting, coating, or winding.

The Anatomy of a High-Performance Bowed Roller

Modern web handling requires durability. Metal expander rollers are often preferred in harsh industrial environments because they resist wear from high temperatures and abrasive materials. The internal construction consists of a curved axle, specialized bearings, and a flexible sleeve (often rubber or metal segments) that allows the roller to rotate smoothly despite its curved shape.

The Critical Role of Spreader Rollers in Web Control

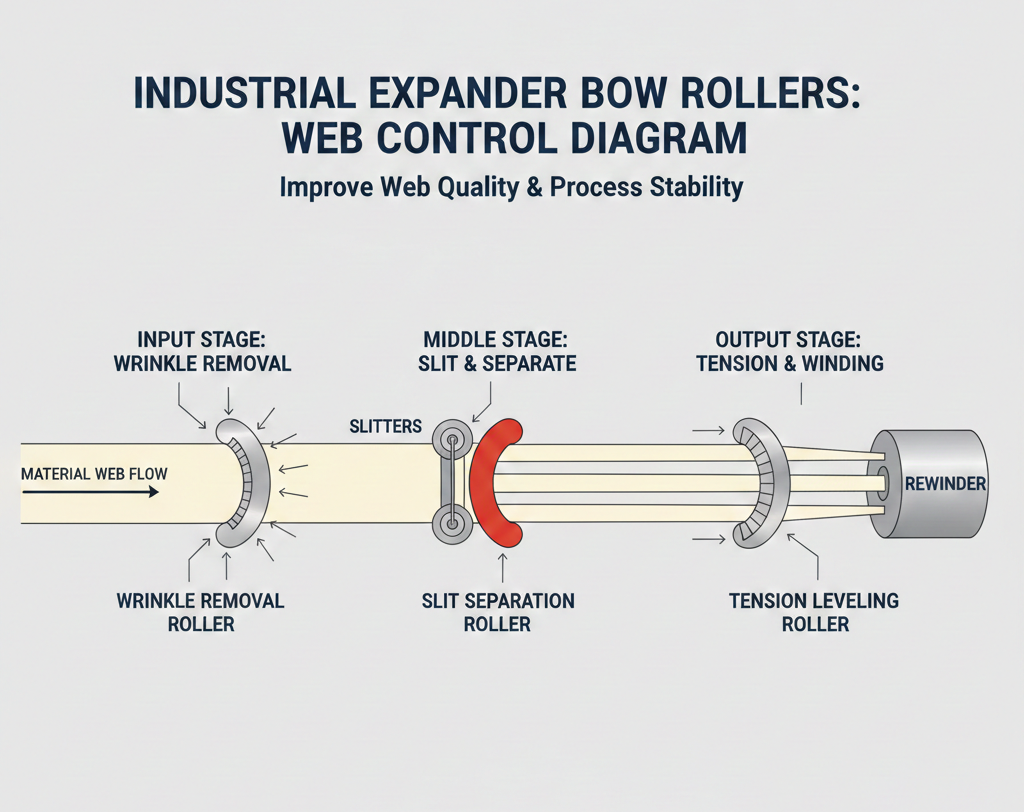

The primary goal of any web-fed process is to maintain “Web Control.” This refers to the ability to manage the position and tension of the material at all times. Here is how spreader rollers contribute to that stability:

1. Superior Wrinkle Removal

Wrinkles are the enemy of quality. They cause uneven coating, improper printing, and weak winding. As wrinkle removal rollers, expander bows work by pulling the web outward. As the material passes over the apex of the curve, any slack in the center is pushed toward the edges, effectively “ironing out” the web in real-time.

2. Slit Separation

If you are operating a slitting machine, you know the frustration of “interweaving”—where individual strips of slit material overlap and stick together during rewinding. By placing an expander roller after the slitting station, the different strands are spread apart, ensuring clean, individual rolls.

3. Tension Equalization

Not all webs are created equal. Sometimes, a roll of material might have a “baggy center” or “tight edges” due to manufacturing defects. Bowed rollers help distribute tension more evenly across the entire width of the web, preventing snaps or distortions.

Enhancing Process Stability: Why It Matters for Your Bottom Line

Process stability isn’t just a technical term; it is a financial necessity. When you incorporate high-quality web handling equipment like those from Siva Rollers, you see immediate improvements in several KPIs:

- Reduced Material Waste: By eliminating wrinkles and creases, you reduce the amount of “scrap” material that ends up in the bin.

- Higher Machine Speeds: When the web is stable and controlled, you can run your machines at higher RPMs without fear of material breakage or misalignment.

- Improved Product Quality: For industries like flexible packaging or high-end textiles, surface perfection is a requirement. Expander rollers ensure a premium finish every time.

Choosing the Right Roller: Metal vs. Rubber Covered

Depending on your specific application, the choice of material for your banana rollers is vital:

- Rubber Covered Bowed Rollers: Ideal for delicate materials like thin films, paper, and foils. The rubber provides a high-friction grip that gently spreads the web without scratching the surface.

- Metal Expander Rollers: These are the workhorses of the industry. Typically made of stainless steel or hard-chromed segments, they are used in high-speed, high-temperature applications or where the web material is abrasive. They offer maximum longevity and precision.

Troubleshooting Common Web Problems with Bowed Rollers

Industrial operators often face the “walking web” problem, where the material drifts to one side. By adjusting the “bow angle” of the roller, operators can steer the web back to the center.

Additionally, if you notice that the edges of your material are curling, a slight adjustment in the position of the spreader rollers can counteract the curl, providing a perfectly flat output for the next stage of production.

Why Siva Rollers is India’s Preferred Partner

When it comes to precision engineering, experience matters. Siva Rollers has established itself as the Best Expander Bow Rollers Manufacturer & Supplier in India by focusing on three core pillars:

- Precision Engineering

Every roller we manufacture is balanced to perfection. We understand that even a millimeter of misalignment can cause vibrations that ruin a web. Our bowed rollers are tested for high-speed performance to ensure zero-vibration operation.

- Custom Solutions for Every Industry

Whether you need a small roller for a label printing press or a massive metal expander roller for a textile processing plant, we customize the bow radius, length, and surface finish to match your specific material needs.

- Durability and Low Maintenance

Industrial environments are tough. Our rollers are built with heavy-duty bearings and reinforced axles to ensure they keep spinning long after the competition’s rollers have failed. This commitment to quality makes us the top choice for web handling equipment across the country.

Key Takeaways for Industrial Operators

To summarize, if you are looking to optimize your production line, you must prioritize the quality of your Expander bow rollers. These components are the key to:

- Effective wrinkle removal.

- Precise slit separation.

- Total web tension management.

- Enhanced process reliability.

By investing in premium banana rollers and spreader rollers, you aren’t just buying a spare part; you are investing in the efficiency and reputation of your manufacturing process.

Contact the Experts Today

Don’t let web instability slow down your growth. If you are struggling with wrinkles, tracking issues, or tension variations, it’s time to upgrade your equipment.

Siva Rollers is dedicated to helping industrial businesses achieve peak performance. As the leading Expander Bow Rollers Manufacturer & Supplier in India, we provide the technical expertise and high-quality hardware you need to stay ahead of the competition.

Looking for a quote or a technical consultation? Reach out to us at Siva Rollers today. Let us help you find the perfect web handling equipment solution to keep your production running smoothly, efficiently, and profitably.

FAQs

An Expander Bow Roller is a curved roller designed to spread web material outward from the center to the edges. It is used in web handling systems to remove wrinkles, stabilize tension, improve tracking, and maintain flatness of materials such as paper, plastic films, textiles, and non-wovens during high-speed production.

Expander Bow Rollers improve web control by equalizing tension across the entire width of the web. As the material passes over the curved surface, slack areas are stretched outward, preventing wrinkles, edge curl, and lateral movement. This ensures consistent alignment throughout the process.

All three terms refer to the same functional component. “Expander Bow Roller” is the technical term, “Banana Roller” describes the curved shape, and “Spreader Roller” highlights its function of spreading the web. The operating principle remains the same across all names.

Industries that process continuous web materials benefit the most, including paper manufacturing, printing, flexible packaging, plastic film extrusion, textile processing, non-woven fabric production, coating lines, laminating machines, and slitting and rewinding operations.

Wrinkles form due to uneven tension or slack in the center of the web. Expander Bow Rollers apply outward force as the web travels over the curved surface, redistributing tension evenly and flattening the material in real time, effectively eliminating wrinkles before they cause defects.

Yes. Expander Bow Rollers help correct web wandering by stabilizing tension across the width. Fine adjustments to the bow angle allow operators to steer the web back to the center, reducing side drift and improving downstream process accuracy.

After slitting, narrow web strips tend to overlap or interweave during rewinding. Installing an Expander Bow Roller immediately after the slitter separates the individual strands, ensuring clean, uniform rewound rolls without sticking or edge damage.

Uneven tension can result from roll defects, baggy centers, tight edges, or inconsistent upstream processing. Bowed rollers compensate for these variations by redistributing tension evenly across the web width, reducing breakage and distortion.

Rubber-covered Expander Bow Rollers are ideal for delicate materials like paper, thin films, and foils because they provide high friction without surface damage. Metal Expander Bow Rollers, typically made from stainless steel or hard-chromed segments, are suited for high-speed, high-temperature, or abrasive applications due to their durability and long service life.

The correct roller depends on web material type, width, thickness, line speed, operating temperature, and process stage. Key factors include bow radius, roller diameter, surface covering, and bearing design. A customized solution ensures optimal performance and long-term stability.

Yes. By stabilizing the web and eliminating defects like wrinkles and misalignment, Expander Bow Rollers allow machines to operate at higher speeds with fewer stoppages, directly improving productivity and throughput.

Absolutely. Improved web control minimizes defects such as creases, coating inconsistencies, and print errors, significantly reducing scrap rates and raw material loss.

High-quality Expander Bow Rollers with precision bearings and balanced construction require minimal maintenance. Regular inspection, proper alignment, and bearing lubrication are typically sufficient for long service life.

Signs include persistent wrinkles, edge curling, uneven tension, or web drifting. Adjusting the bow angle or roller position usually resolves these issues quickly without stopping production for extended periods.

Precision balancing prevents vibration at high speeds. Even slight imbalance can cause web instability, bearing failure, or surface defects. Well-balanced rollers ensure smooth rotation and consistent performance.

Yes. Customization options include roller length, bow curvature, shaft design, surface coating, and bearing configuration. Custom-built rollers ensure compatibility with specific machinery and material requirements.

Siva Rollers is recognized for precision engineering, custom-built solutions, high-speed balancing, durable construction, and deep expertise in web handling applications across industries. Their rollers deliver long-term reliability and process stability in demanding industrial environments.

They create a stable, flat, and well-controlled web path, reducing fluctuations in tension and alignment. This stability improves coating uniformity, print quality, winding consistency, and overall production efficiency.

Yes. When properly designed and balanced, Expander Bow Rollers perform effectively across a wide range of speeds, from slow coating lines to ultra-high-speed printing and converting machines.