Hard Chrome Plated Rollers for Industrial Machines: Performance, Life & Cost Benefits

In the demanding world of high-speed manufacturing, the reliability of your machinery often hinges on the quality of a single component: the hard chromer plated roller. Whether you are running a printing press, a textile mill, or a steel rolling plant, your equipment is only as efficient as its contact surfaces.

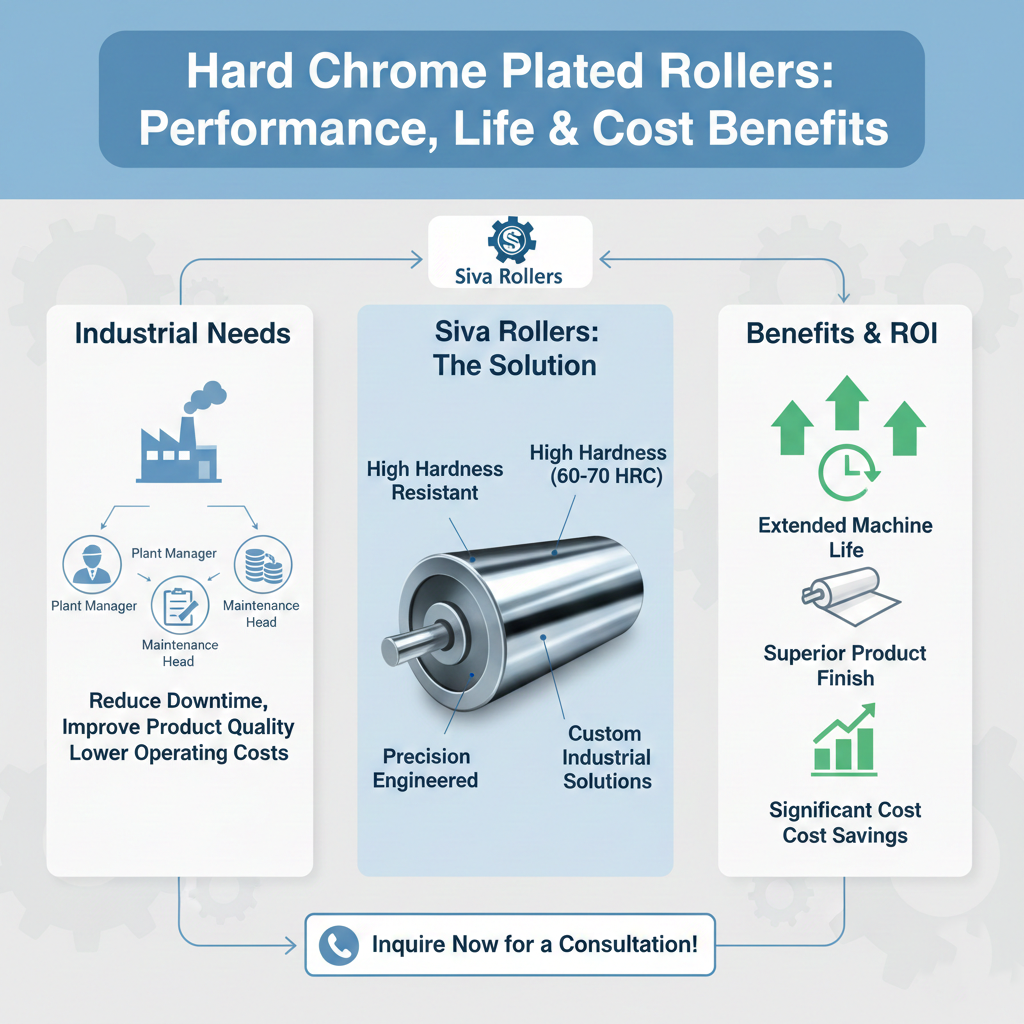

As a seasoned Hard Chrome Plated Roller Manufacturer, we understand that plant managers and maintenance heads aren’t just looking for a part; they are looking for a way to reduce downtime and improve output quality. Hard chrome plating isn’t just an aesthetic finish—it is a critical engineering process that transforms a standard steel tube into a high-performance industrial asset.

What Is a Hard Chrome Plated Roller and Why Industries Use It

A Chrome Coated Roller is a precision-engineered steel or alloy roller with a layer of hard chrome electroplated on its surface. This chrome layer is extremely hard, smooth, and wear-resistant.

Hard chrome plating is used because it delivers three things industries value most:

- High surface hardness

- Excellent wear and corrosion resistance

- Consistent dimensional accuracy over long runs

A reliable Hard Chrome Plated Roller Manufacturer controls coating thickness, hardness, surface finish, and grinding accuracy. This ensures the roller performs consistently under heavy industrial loads.

Key Industrial Performance Benefits of Hard Chrome Plated Rollers

1. High Hardness for Continuous Operation

A High Hardness Chrome Plated Roller typically has surface hardness in the range of 60–70 HRC. This hardness protects the roller from scratches, dents, and deformation during continuous operation.

In high-speed lines or machines running 24/7, softer rollers wear quickly. Chrome plated rollers maintain surface integrity even under pressure, friction, and heat.

This directly improves machine stability and reduces frequent roller replacements.

2. Excellent Wear Resistance in Harsh Conditions

Industries deal with abrasive materials, chemicals, inks, adhesives, and dust. A Wear Resistant Chrome Plated Roller acts as a protective barrier between the base metal and these harsh elements.

The chrome surface resists:

- Abrasive wear

- Chemical corrosion

- Moisture and humidity damage

This makes chrome coating rollers ideal for printing presses, coating machines, calendering lines, and material handling systems where roller damage is common.

3. Smooth Surface for Better Product Quality

Surface finish matters more than many realize. Uneven or worn rollers lead to marks, thickness variation, and product rejection.

A properly finished Chrome Coated Roller Manufacturer ensures:

- Uniform coating thickness

- Precision grinding and polishing

- Controlled surface roughness

The result is smoother material flow, consistent coating application, and improved final product appearance—without constant machine adjustments.

Longer Roller Life Means Lower Maintenance Cost

Reduced Downtime and Fewer Replacements

One of the biggest cost benefits of a Heavy Duty Chrome Plated Roller is its long service life. Compared to uncoated or soft-coated rollers, chrome plated rollers last significantly longer.

For maintenance heads, this means:

- Fewer shutdowns

- Lower spare inventory cost

- Reduced labor hours for roller change

Instead of frequent repairs, the plant can focus on production efficiency.

Re-Chroming Extends Life Further

Another industrial advantage is reusability. A quality Hard Chrome Plated Roller Supplier designs rollers that can be re-ground and re-chromed multiple times.

This allows industries to:

- Restore original performance

- Avoid purchasing new rollers

- Control long-term capital expenses

From a cost-per-hour perspective, chrome plated rollers deliver excellent value.

Where Hard Chrome Plated Rollers Are Commonly Used

A Hard Chrome Plated Roller for Industrial Machines is widely used across sectors, including:

- Printing and packaging machines

- Paper mills and coating lines

- Plastic film and lamination plants

- Steel processing and sheet handling

- Textile finishing and calendaring

- Rubber, adhesive, and chemical industries

In all these applications, the roller must withstand load, speed, heat, and friction without losing accuracy.

Why Choosing the Right Hard Chrome Plated Roller Manufacturer Matters

Not all chrome plated rollers perform the same. Many industrial problems come from poor coating quality, uneven thickness, or improper grinding.

An experienced Hard Chrome Plated Roller Manufacturer focuses on:

- Proper base material selection

- Controlled electroplating process

- Uniform chrome thickness

- Precision cylindrical grinding

- Final inspection and testing

These factors determine whether the roller performs reliably for years or fails prematurely.

Industries planning to reduce maintenance cost and improve machine efficiency should consult a manufacturer who understands application-specific requirements rather than offering generic rollers.

Custom Chrome Coating Rollers for Industrial Needs

Every machine operates differently. Load, speed, temperature, and environment vary from plant to plant.

A professional Chrome Coated Roller Manufacturer offers customized solutions such as:

- Application-specific hardness levels

- Special surface finishes

- Anti-corrosion or micro-crack controlled chrome

- Heavy-duty designs for high load machines

This customization ensures the roller fits the process, not the other way around.

Siva Rollers – Best Hard Chrome Plated Rollers Manufacturer & Supplier in India

Siva Rollers is a trusted name in industrial roller manufacturing, known for supplying reliable and long-lasting chrome plated rollers across India.

As a leading Hard Chrome Plated Roller Manufacturer & Supplier, Siva Rollers offers:

- Advanced chrome plating facilities

- Precision grinding and polishing

- High-quality raw materials

- Custom-built rollers for industrial machines

- Consistent performance for long-term use

Industries choose Siva Rollers because the focus is not just on coating, but on overall roller performance, durability, and reliability.

Their experience across multiple industries allows them to recommend the right chrome coating solution based on real operating conditions.

How Hard Chrome Plated Rollers Improve Overall Plant Efficiency

When machines run smoothly, everything else improves. Chrome plated rollers contribute to:

- Stable machine speed

- Reduced vibration

- Lower product rejection

- Predictable maintenance schedules

Over time, these benefits translate into better productivity and cost control—key concerns for factory owners and operations teams.

Final Thoughts: A Smart Investment for Industrial Operations

Hard chrome plated rollers are not a luxury component. They are a strategic investment for industries that value reliability, consistency, and long-term cost savings.

Choosing the right Hard Chrome Plated Roller Manufacturer, using proper chrome coating rollers, and applying them correctly can significantly improve machine performance and reduce operational headaches.

Industries looking to enhance machine performance, extend roller life, and reduce maintenance costs should connect with an experienced Hard Chrome Plated Roller Manufacturer.

For customized solutions, technical consultation, or a quotation, Siva Rollers – Best Hard Chrome Plated Rollers Manufacturer & Supplier in India offers proven expertise and dependable industrial support.

A well-engineered chrome plated roller today can save years of maintenance cost tomorrow.

CONTACT US

FAQs

A hard chrome plated roller is used in industrial machines to handle continuous operation under load, friction, and harsh environments. The chrome coating provides high hardness, smooth surface finish, and wear resistance, making it suitable for printing, packaging, paper, plastic, textile, and steel processing machines.

A hard chrome plated roller improves machine performance by reducing surface wear, maintaining dimensional accuracy, and ensuring smooth material movement. This leads to stable machine speed, fewer vibrations, better product quality, and less frequent machine adjustments during production.

A chrome coated roller generally refers to any roller with chrome on the surface, while a hard chrome plated roller uses industrial-grade hard chrome with controlled thickness and hardness. Hard chrome plating offers significantly better wear resistance, surface hardness, and service life compared to decorative or light chrome coatings.

Hard chrome plated rollers are cost-effective because they last longer, reduce maintenance frequency, and minimize machine downtime. They can also be re-ground and re-chromed, which extends their usable life and lowers long-term replacement costs for industrial plants.

The life of a hard chrome plated roller depends on operating conditions such as load, speed, and environment. In most industrial applications, a properly manufactured roller lasts several times longer than uncoated rollers and can be refurbished multiple times through re-chroming.

Yes, a professional hard chrome plated roller manufacturer can customize rollers based on machine design, operating load, surface finish requirements, and industry application. Customization ensures optimal performance and longer service life in specific industrial processes.

Yes, heavy duty chrome plated rollers are specifically designed to handle high-speed and high-load applications. Their high surface hardness and wear resistance make them suitable for continuous industrial operations without premature failure.

Hard chrome plated rollers are widely used in printing, packaging, paper mills, plastic film processing, textile finishing, steel processing, coating machines, and material handling systems where durability and surface consistency are critical.

Industries should look for a manufacturer with proven experience, controlled chrome plating processes, precision grinding capability, quality inspection systems, and the ability to provide application-specific solutions rather than standard rollers.

Siva Rollers is trusted for its manufacturing expertise, consistent chrome coating quality, precision finishing, and ability to deliver customized industrial solutions. Their hard chrome plated rollers are designed for long-term reliability and performance across multiple industries in India.

Yes, worn hard chrome plated rollers can be re-ground and re-chromed by an experienced hard chrome plated roller supplier. This process restores surface hardness and finish, making the roller usable again and reducing overall equipment costs.

Hard chrome plated rollers reduce maintenance downtime by resisting wear, corrosion, and surface damage. Since they maintain performance for longer periods, machines require fewer shutdowns for roller replacement or surface correction.