How to Select the Best Stainless Steel Roller for Printing & Processing Machines

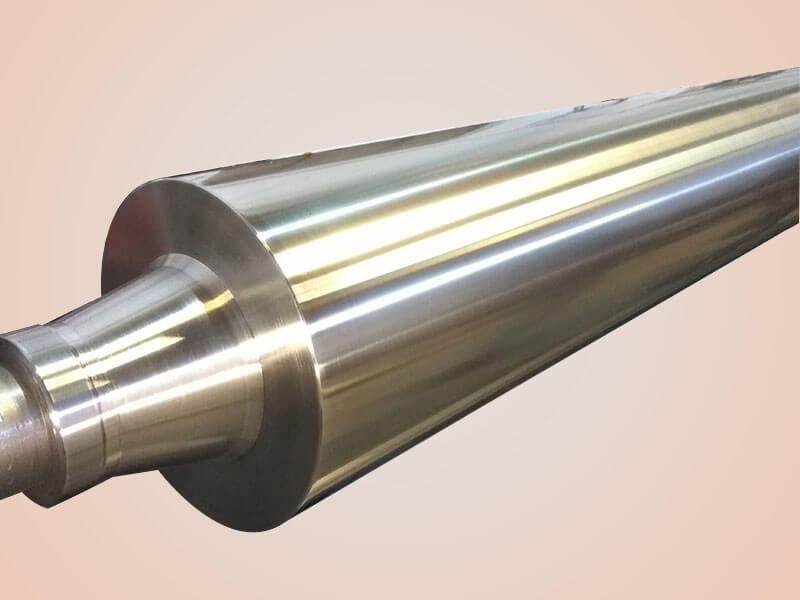

In the high-speed world of industrial manufacturing, the efficiency of your production line often comes down to the smallest components. For plant managers, printing unit owners, and machine manufacturers, few components are as critical as the Stainless Steel Roller. Whether you are involved in flexible packaging, textile processing, or paper manufacturing, the quality of your rollers dictates the quality of your final product.

Selecting the right Industrial Stainless Steel Rollers is not just a procurement task; it is a strategic decision that impacts machine uptime, maintenance costs, and brand reputation. As a leading Stainless Steel Roller Manufacturer in India, Siva Rollers understands that a “one size fits all” approach leads to operational failure.

This comprehensive guide will walk you through the essential factors to consider when choosing rollers for your printing and processing machines to ensure long-term ROI and peak performance.

The Critical Role of SS Rollers in Modern Machinery

A Printing Machine Roller does more than just rotate. It must provide consistent tension, maintain precise alignment, and withstand constant exposure to chemicals, inks, and varying temperatures. If a roller fails or develops surface imperfections, the entire batch of material can be ruined, leading to significant financial losses.

Many industrial buyers face common pain points that can be traced back to poor-quality rollers:

- Corrosion: Exposure to moisture, cleaning agents, or chemicals leads to pitting and oxidation.

- Surface Wear: Low-grade steel results in scratches that transfer directly to the printed substrate.

- Vibration and Noise: Poorly balanced rollers cause machine instability, damaging bearings and motors.

- Downtime: Frequent replacements halt production schedules and balloon maintenance budgets.

By partnering with an industry-experienced company like Siva Rollers, you can mitigate these risks through engineered solutions designed specifically for your application.

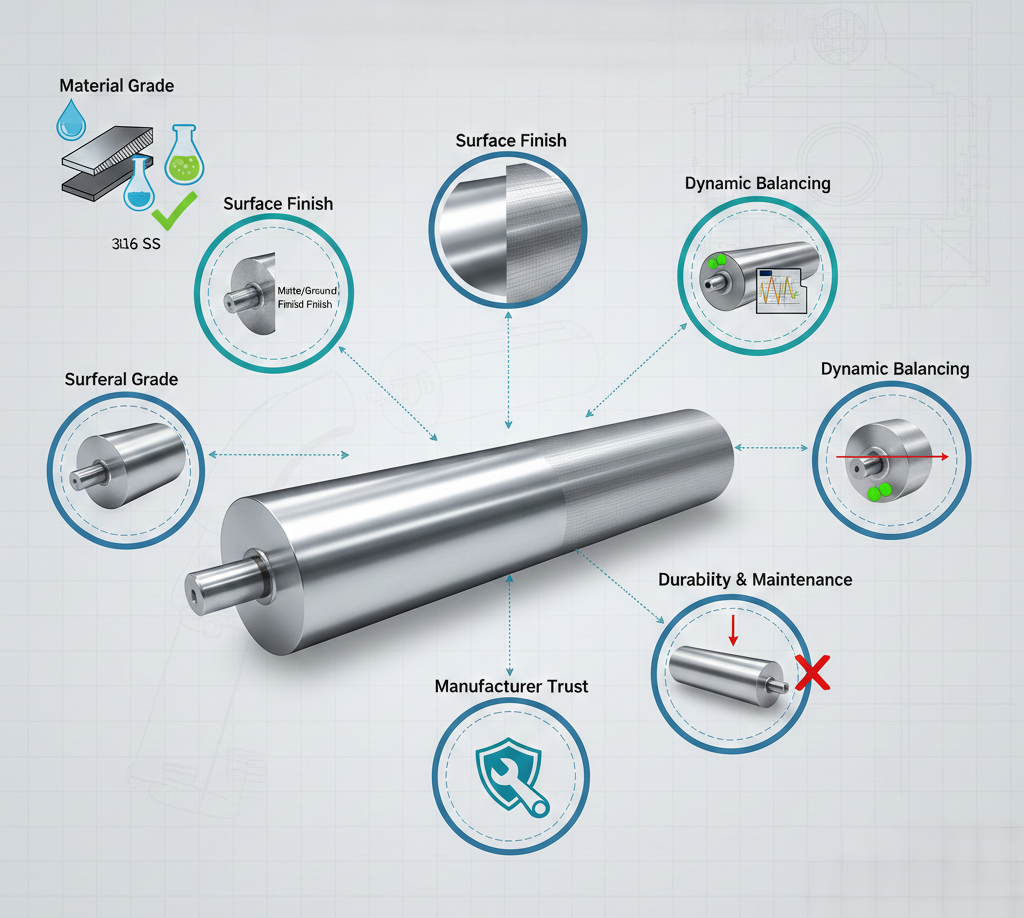

1. Prioritize Material Grade for Corrosion Resistance

The first step in selecting a Stainless Steel Roller is identifying the correct grade of steel. In the printing and processing industry, rollers are frequently exposed to cleaning solvents, water-based inks, and high humidity. Using high-quality materials is essential to overcome these challenges.

- SS 304: This is the standard grade for many industrial applications. It offers excellent value and good corrosion resistance for general processing environments.

- SS 316: For environments involving high salinity, aggressive chemicals, or acidic inks, SS 316 is the superior choice. Its molybdenum content provides enhanced resistance to pitting and crevice corrosion.

When you request a quotation from a trusted Stainless Steel Roller Supplier, ensure you discuss the specific chemical environment of your facility. Choosing the wrong grade can lead to premature rusting, which is a leading cause of machinery downtime.

2. Focus on Surface Finish and Precision Machining

In the printing industry, the surface of the roller is where the “magic” happens. A Printing Roller Manufacturer in India must provide various finishes depending on the specific machine application.

- Mirror Finish: This is essential for high-quality printing where even the slightest surface scratch can cause a defect in the final output.

- Matte or Ground Finish: Typically used in processing machines where grip and traction are more important than aesthetic clarity.

- Custom Coatings: Sometimes, a Stainless Steel Roller product page might offer additional surface treatments like hard chrome plating to further increase surface hardness and wear resistance.

A high-quality SS Roller for Printing Machines must be precision-ground to ensure total indicated runout (TIR) is kept to a minimum. At Siva Rollers, we emphasize that precision at the manufacturing stage translates to stability at the production stage. If your roller is not perfectly cylindrical, it will cause “chatter marks” or uneven ink distribution on your materials.

3. Dynamic Balancing for High-Speed Operations

As processing speeds increase to meet global demand, the importance of dynamic balancing cannot be overstated. An unbalanced roller creates centrifugal forces that vibrate the entire machine frame. This not only affects the print quality (leading to registration issues) but also accelerates the wear and tear on expensive machine bearings.

When selecting a Stainless Steel Roller Manufacturer, ask about their balancing protocols. High-performance Industrial Stainless Steel Rollers should be dynamically balanced to specific ISO standards to ensure smooth operation at maximum RPMs. This attention to detail is what separates a standard supplier from a custom roller solution provider.

4. Understanding Load Capacity and Deflection

Every roller has a physical limit. “Deflection” occurs when a roller bows under the weight of the material or the high tension applied during processing. Even a few microns of deflection can cause uneven pressure across the web, leading to wrinkles in the fabric, film, or paper.

Industrial buyers must work with a trusted manufacturer that can calculate the necessary wall thickness and internal reinforcement required for their specific machine width and load. A hollow Processing Machine Roller might be lightweight and cost-effective, but for heavy-duty applications, a solid shaft or reinforced internal structure is necessary to maintain structural integrity.

5. Ease of Maintenance and Long-Term Durability

The best roller is the one you don’t have to think about. Stainless steel is often preferred over carbon steel or simple chrome-plated rollers because it does not flake or peel over time. While chrome plating is excellent for hardness, it can eventually chip if the base metal is not handled correctly, exposing the vulnerable metal underneath to rust.

By choosing high-quality rollers from a dedicated Printing Roller page, you are investing in a component that offers:

- High Hardness: To resist scratches from doctors blades or abrasive materials.

- Hygiene: Easy cleaning and sterilization, which is critical for food-grade packaging.

- Thermal Stability: The ability to operate in high-temperature coating or drying sections without warping.

Why the Manufacturer Matters: The Siva Rollers Advantage

The Indian manufacturing landscape is vast, but finding a reliable Stainless Steel Roller Manufacturer in India requires due diligence. A manufacturer should not just be a vendor; they should be a technical partner who understands the nuances of tension control and surface dynamics.

Siva Rollers has built a reputation as a trusted manufacturer by focusing on the specific needs of the printing and processing sectors. Our 10+ years of experience allows us to identify potential issues—such as bearing fitment or material compatibility—before the rollers even reach your factory floor.

Whether you are looking for a standard replacement or a completely custom-engineered solution for a new processing line, we provide the technical expertise needed to keep your machines running at peak efficiency.

Key Considerations for Global & Export Buyers

For export and global industrial buyers, reliability and documentation are paramount. Ensure your supplier follows international quality benchmarks. Using high-grade raw materials and advanced CNC machining ensures that the rollers you receive in Europe, the Middle East, or Southeast Asia are of the same caliber as those used in top-tier units in India.

Making the Right Choice for Your Production Line

Selecting the best Stainless Steel Roller for your printing or processing machine involves balancing material science, mechanical engineering, and supplier trust. By focusing on the correct SS grade, insisting on precision surface finishing, and ensuring dynamic balancing, you protect your machinery and your bottom line.

A high-performing production line is only as strong as its weakest roller. Don’t let a low-quality component become a bottleneck in your business growth.

Ready to upgrade your machine performance?

As a premier Stainless Steel Roller Manufacturer in India, Siva Rollers is dedicated to providing high-durability, precision-engineered solutions for the global market.

Contact our experts today to discuss your requirements or get a custom solution tailored to your specific processing needs. Let us help you achieve the perfect finish for your products.

- Call / WhatsApp: +91 75070 10009

- Email: info@sivarollers.com

FAQs

The choice depends on the environment. SS 304 is the industry standard for general processing due to its excellent durability and cost-effectiveness. However, for environments involving high salinity, acidic inks, or aggressive chemicals, SS 316 is the best choice because its molybdenum content provides superior corrosion and pitting resistance.

Dynamic balancing is essential because it eliminates centrifugal forces that cause machine vibration. At high speeds, an unbalanced roller leads to registration issues, "chatter marks" on prints, and accelerated wear on expensive bearings and motors. Balanced rollers ensure smooth operation and a longer machine lifespan.

The finish should match your application:

- Mirror Finish: Best for high-precision printing where any surface imperfection could transfer to the substrate.

- Matte or Ground Finish: Ideal for processing lines where traction and grip are required to move material without slipping.

- Hard Chrome Plating: Used when extreme surface hardness and wear resistance are needed for abrasive materials.

Deflection is the "bowing" of a roller under the weight of the material or high tension. It can be prevented by:

- Calculating the correct wall thickness for the roller.

- Using a solid shaft or reinforced internal structures for wider machines.

- Consulting with a manufacturer to match the roller’s structural integrity to your specific load requirements.

Yes, in most long-term applications. While chrome-plated carbon steel is hard, the plating can chip or flake over time, exposing the base metal to rust. Stainless steel is corrosion-resistant throughout, offering better hygiene (critical for food packaging) and thermal stability without the risk of surface peeling.

TIR (Total Indicated Runout) measures the "roundness" or concentricity of the roller as it rotates. A low TIR is vital for high-speed printing; if a roller is not perfectly cylindrical, it creates uneven pressure, leading to inconsistent ink distribution and material wrinkling.

By using high-grade stainless steel (like SS 304 or 316), you significantly reduce the frequency of corrosion-related failures and surface scratches. This leads to fewer maintenance shutdowns, lower replacement costs, and consistent production quality, ultimately improving your ROI.

Absolutely. Stainless steel offers excellent thermal stability, meaning it can operate in high-heat coating or drying sections without warping or losing structural integrity, unlike rollers made from synthetic materials or lower-grade alloys.

When evaluating a Stainless Steel Roller Manufacturer in India, prioritize:

- Material Certification: Verification of SS 304/316 grades.

- Machining Capabilities: Precision grinding and CNC capabilities.

- Balancing Standards: Adherence to ISO dynamic balancing standards.

- Industry Experience: A proven track record in your specific sector (e.g., textiles or packaging).

In flexible packaging, even a microscopic scratch on a roller can cause a visible defect or a "pinhole" in thin films. A mirror-finished SS roller ensures a flawless contact surface, which is critical for maintaining the barrier properties and aesthetic quality of the packaging material.

To maintain peak performance, clean rollers using non-abrasive solvents and soft lint-free cloths to avoid micro-scratches.

- Daily: Wipe down to remove ink or chemical residue.

- Weekly: Inspect bearings for lubrication and check for any surface pitting.

- Avoid: Never use steel wool or chloride-based cleaners, as these can damage the protective oxide layer of the stainless steel.

The price of stainless steel rollers is not calculated solely by weight but by material grade (SS 304 vs 316), machining complexity, and surface finish requirements. As of early 2026, raw stainless steel prices fluctuate, but the value-add of precision grinding and dynamic balancing typically accounts for a significant portion of the final quote. Contact a supplier for a custom estimate.

The primary difference is corrosion resistance.

- SS 304 contains Chromium and Nickel, making it ideal for standard industrial use.

- SS 316 contains an added 2-3% Molybdenum, which provides superior protection against chlorides, saline environments, and aggressive chemical solvents used in specific printing inks.

In film lamination, any surface variation causes air bubbles or "silvering" (delamination). Precision ground rollers ensure a perfectly consistent nip pressure across the entire width of the film. A low TIR (Total Indicated Runout) is non-negotiable here to ensure the film stays flat and wrinkle-free during the high-speed bonding process.