Benefits of Using Ebonite Coated Rollers in Printing & Packaging

In the fast-paced printing and packaging industry, precision, durability, and cost-effectiveness are essential for every business to maintain efficiency and quality output. Among the many components used in these industries, the Ebonite Coated Roller plays a crucial role in ensuring smooth, consistent, and high-quality production. Designed to offer excellent resistance, grip, and performance, these rollers are the backbone of printing and packaging machines worldwide. Whether it’s offset printing, flexographic processes, or packaging line operations, Ebonite Rubber Rollers provide unmatched reliability.

For businesses looking to improve efficiency and reduce downtime, understanding the benefits of Ebonite Coated Rollers can help in making the right choice. Let’s explore in detail how these rollers enhance operations and why partnering with a trusted manufacturer like Siva Rollers – the Best Ebonite Coated Roller Manufacturer in India – is a smart investment for every printing and packaging company.

What Makes Ebonite Coated Rollers So Effective?

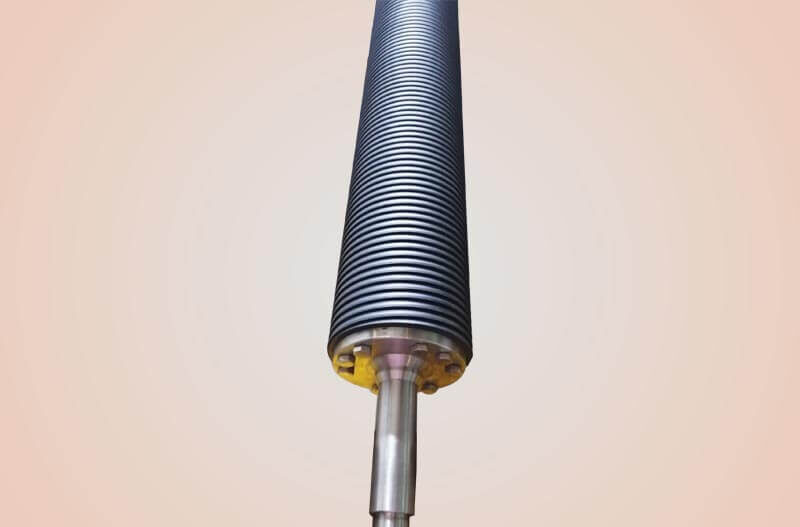

Ebonite Coated Rollers, often called Ebonite Rubber Rollers, are made using hard rubber (vulcanized natural or synthetic rubber) that provides a tough, resilient coating over the roller’s surface. This coating is known for its exceptional durability, high resistance to chemicals, and ability to maintain a consistent grip and pressure during machine operations.

In printing and packaging lines, where rollers constantly interact with inks, coatings, films, and papers, the stainless ebonite-coated roller ensures minimal wear and tear while maintaining a uniform performance. Its unique structure allows it to withstand continuous operation without losing shape, which reduces maintenance costs and machine downtime.

Superior Durability for High-Volume Operations

The printing and packaging industries deal with high-speed production lines where machines often run 24/7. Ordinary rollers can wear out quickly under such conditions, leading to frequent replacements and production delays. Ebonite Rubber Rollers solve this problem with their hard, dense rubber coating that resists abrasion and mechanical stress.

The ebonite coated roller construction adds even more strength by combining the corrosion resistance of stainless steel with the longevity of ebonite coating. This combination ensures that rollers maintain their structural integrity and surface finish, even under demanding production environments.

Excellent Chemical and Heat Resistance

One of the biggest advantages of stainless steel guide rollers is their long-term durability. Businesses save significantly on maintenance and replacement costs by investing in rollers that do not wear out quickly, even in high-friction or corrosive environments. Stainless steel’s natural strength ensures these rollers handle demanding applications without bending or deforming under load.

These rollers also enhance operational efficiency. By guiding materials accurately through production lines, they reduce wastage, minimize jams, and allow faster processing speeds. This makes them especially useful in industries where precision is crucial, such as printing, where even minor deviations can lead to product rejections.

Furthermore, stainless steel rollers provide versatility. They can be customized in size, surface finish, and bearing types to suit different machinery, making them adaptable for everything from lightweight packaging films to heavy industrial sheets. Their non-reactive properties also make them a preferred choice in sensitive industries like pharmaceuticals and food, where contamination risks must be minimized.

Why Siva Rollers is the Leading Stainless Steel Guide Roller Manufacturer in India

One of the most significant advantages of Ebonite Coated Rollers in printing and packaging is their ability to resist chemical damage. Printing processes often involve inks, solvents, adhesives, and cleaning agents that can damage regular rubber rollers. Ebonite’s vulcanized surface provides strong chemical resistance, ensuring the roller doesn’t swell, crack, or degrade.

Additionally, Ebonite Rubber Rollers can withstand a wide range of temperatures, which is crucial in packaging lines where heat treatments or high-speed friction can cause thermal stress. Their heat resistance ensures smooth operations without the risk of warping or deforming.

Consistent Performance for Quality Printing & Packaging

For printing companies, precision is non-negotiable. An uneven roller surface or inconsistent pressure can lead to poor ink transfer, blurred prints, or damaged substrates. Ebonite Coated Rollers deliver consistent contact pressure, ensuring flawless ink distribution and smooth substrate handling.

In packaging lines, these rollers provide excellent grip and traction, helping in film lamination, cutting, and sealing processes without slippage. The uniformity and reliability of these rollers significantly reduce production errors, helping businesses maintain the highest product quality.

Cost-Effective and Low Maintenance

While Ebonite Rubber Rollers may have a slightly higher upfront cost compared to basic rubber rollers, their long lifespan and low maintenance requirements make them highly cost-effective. Since these rollers are resistant to wear, corrosion, and chemical damage, they last significantly longer, reducing replacement frequency.

Their low-maintenance nature also minimizes machine downtime, which translates into better productivity and profitability for businesses. Over time, the investment in ebonite coated rollers pays off by lowering operational costs and improving efficiency.

Versatility Across Printing & Packaging Applications

Ebonite Coated Rollers are not limited to a single type of machinery. They are widely used in:

- Offset Printing Machines – for ink transfer and pressure balancing.

- Flexographic Printing – where durability and ink resistance are crucial.

- Gravure Printing – ensuring even pressure and smooth operation.

- Lamination and Coating Lines – for consistent film and adhesive application.

- Packaging Equipment – assisting in sealing, slitting, and film handling.

This versatility makes them an indispensable component for manufacturers looking for one solution that fits multiple operational needs.

Why Choose Siva Rollers for Ebonite Coated Rollers?

When it comes to sourcing Ebonite Rubber Rollers or Ebonite Coated Rollers, selecting the right manufacturer is critical. Siva Rollers, one of the best ebonite coated roller manufacturers in India, offers rollers engineered to meet the most demanding industrial requirements.

Siva Rollers combines premium-grade raw materials, precision engineering, and advanced coating techniques to manufacture rollers that deliver exceptional performance. Whether you run a small printing shop or a large-scale packaging plant, Siva Rollers provides customized solutions to suit your specific machinery and production needs. Their rollers are designed to last, reduce downtime, and enhance the efficiency of your operations.

Eco-Friendly and Sustainable Operations

Another advantage of Ebonite Coated Rollers is their environmentally friendly nature. Due to their long lifespan and low replacement rates, they help reduce industrial waste. Their resistance to chemicals also ensures fewer leaks, spills, and contaminations, contributing to a cleaner, safer working environment.

For companies aiming to adopt more sustainable practices, investing in durable, high-performance rollers like these helps minimize their carbon footprint while maintaining operational excellence.

Boosting Productivity with Ebonite Rubber Rollers

In today’s competitive market, productivity and efficiency directly impact profitability. Ebonite Rubber Rollers enable printing and packaging businesses to operate at maximum capacity by reducing maintenance needs, preventing quality issues, and ensuring faster turnaround times.

With their superior grip, consistent performance, and long life, these rollers not only streamline operations but also ensure customer satisfaction by delivering high-quality results every time. Businesses that switch to stainless ebonite coated rollers often experience a noticeable improvement in output and profit margins.

Final Thoughts

The printing and packaging industries rely heavily on precision and reliability, and Ebonite Coated Rollers are integral to achieving both. With their unmatched durability, chemical resistance, and performance consistency, these rollers are an investment that pays off through reduced downtime, lower maintenance, and superior output quality.

For businesses seeking a trusted partner to supply these critical components, Siva Rollers stands out as the best ebonite coated roller manufacturer in India, offering tailor-made solutions for every need. By choosing high-quality Ebonite Rubber Rollers, companies can enhance efficiency, improve product quality, and gain a competitive edge in their industry.

FAQs

An Ebonite Coated Roller is a hard rubber-coated roller used in printing machines for smooth ink transfer, pressure control, and durability in high-speed operations.

It maintains consistent pressure and ink distribution, ensuring sharp, uniform prints without smudging or uneven coverage.

Yes, these rollers provide excellent grip, chemical resistance, and durability, making them ideal for packaging lines, lamination, and sealing applications.

With proper care, these rollers can last several years, thanks to their resistance to abrasion, heat, and chemicals, which reduces wear and replacement costs.

Yes, ebonite’s vulcanized surface resists heat and solvents, making it ideal for printing and packaging processes involving inks, adhesives, and cleaning agents.

Siva Rollers is one of the best ebonite coated roller manufacturers in India, offering precision-engineered, durable rollers for printing and packaging industries.

Yes, due to their long lifespan and low replacement frequency, they reduce industrial waste, supporting sustainable and eco-friendly manufacturing practices.

You can buy premium-quality Ebonite Rubber Rollers from Siva Rollers, a trusted manufacturer supplying customized solutions across India.

They are used in offset, flexographic, gravure printing, lamination machines, and packaging equipment for smooth handling and consistent output.