Best Anti-Deflection Rollers in India – Trusted Manufacturers & Buying Guide

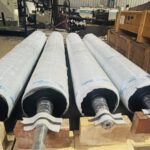

In modern industries where precision, consistency, and performance are non-negotiable, the role of Anti-Deflection Rollers has become increasingly important. These specialized rollers are designed to withstand heavy loads, maintain dimensional accuracy, and reduce roller bending or deflection during operations. Whether in printing, packaging, textiles, or converting applications, choosing the right Anti-Deflection Roller can directly impact product quality and overall production efficiency.

India, being one of the fastest-growing hubs for industrial roller technology, offers multiple options when it comes to trusted suppliers. But with so many choices in the market, buyers often face a critical question: How do you identify the best Anti-Deflection Rollers in India and select the right manufacturer? This detailed guide will walk you through everything you need to know—from features and benefits to selection tips and leading manufacturers.

Why Anti-Deflection Rollers are Crucial for Industries

Unlike standard rollers, which can bend or deflect under pressure, Anti-Deflection Rollers are engineered with reinforced cores, high-performance coatings, and precision balancing to resist deformation. This ensures consistent line pressure, uniform contact, and better alignment throughout operations.

Industries that deal with high-tension materials such as flexible packaging films, laminates, textiles, and paper heavily rely on Anti-Deflection Rollers to achieve accurate results. Deflection in rollers often leads to uneven coating, poor printing registration, and reduced product quality. By investing in high-quality Anti-Deflection Rollers in India, companies can minimize downtime, extend equipment lifespan, and enhance productivity.

Key Features of High-Quality Anti-Deflection Rollers

The effectiveness of a roller depends on its engineering and build quality. Some of the critical features to look for when evaluating Anti-Deflection Rollers include:

- Reinforced Core Design – A strong inner shaft made of alloy steel or specialized composites that provides rigidity under heavy load.

- Precision Grinding & Balancing – Ensures smooth rotation, vibration-free operation, and better material handling.

- Superior Coatings – Ebonite, rubber, or polyurethane coatings that resist wear, abrasion, and chemical exposure.

- Load-Bearing Capacity – Rollers designed to carry uniform load distribution across their length without bending.

- Longer Service Life – Built to withstand demanding industrial environments with minimal maintenance.

These features are not just technical specifications; they translate into real-world benefits such as higher production efficiency, better product consistency, and cost savings over time.

Applications of Anti-Deflection Rollers in India

The demand for Anti-Deflection Rollers in India is spread across multiple sectors. Some of the common applications include:

- Printing & Packaging – For precise tension control and uniform ink transfer in high-speed presses.

- Textile Industry – Ensuring even fabric treatment during processes like dyeing, coating, or lamination.

- Paper & Pulp Industry – Maintaining sheet flatness and avoiding wrinkles during processing.

- Plastic Film & Converting – Providing consistent performance in lamination, extrusion, and slitting machines.

- Industrial Coating – For uniform layer application without roller deflection, ensuring surface quality.

By choosing a trusted Anti-Deflection Rollers Manufacturer in India, industries can ensure they are using rollers that align with their specific process needs.

Factors to Consider Before Buying Anti-Deflection Rollers

Selecting the right roller is not just about specifications—it’s about aligning technology with operational demands. When buying Anti-Deflection Rollers in India, consider the following points:

- Material Compatibility – Ensure the roller coating matches the material being processed (rubber, PU, or chrome-coated as per requirement).

- Load & Pressure Requirements – Choose a roller engineered for the level of pressure your machine applies.

- Customization Options – Reputed manufacturers provide tailored solutions in terms of diameter, length, and coating type.

- After-Sales Support – A reliable supplier should offer installation guidance, technical support, and re-coating services.

- Manufacturer Reputation – Working with a trusted Anti-Deflection Rollers Manufacturer in India ensures product reliability, adherence to standards, and long-term performance.

Why Manufacturer Selection Matters

The performance of Anti-Deflection Rollers depends heavily on the expertise of the manufacturer. Poorly engineered rollers may initially appear cost-effective but can lead to frequent breakdowns, uneven quality, and higher long-term expenses. A reputable manufacturer invests in advanced machinery, precision grinding technology, and quality raw materials to ensure every roller performs flawlessly.

One such trusted name is Siva Rollers, widely recognized as the Best Anti-Deflection Rollers Manufacturer in Ahmedabad, India. With years of experience in producing high-performance industrial rollers, Siva Rollers combines technical expertise with innovation to deliver rollers that meet the toughest industrial challenges. Their rollers are designed for durability, precision, and efficiency—making them a preferred choice for businesses across India.

Benefits of Using Anti-Deflection Rollers

When industries invest in premium Anti-Deflection Rollers, the advantages extend far beyond initial performance. Some of the key benefits include:

- Higher Productivity – Consistent tension and pressure allow machines to run at higher speeds without compromising quality.

- Improved Product Quality – Uniform coating, printing, or lamination results in fewer rejections and better end-product finish.

- Reduced Maintenance Costs – Durable construction reduces the frequency of repairs and replacements.

- Energy Efficiency – Smooth-running rollers reduce friction, thereby lowering energy consumption.

- Operational Reliability – Better stability ensures uninterrupted production runs and reduced downtime.

These benefits make Anti-Deflection Rollers not just a machine component, but a strategic investment for long-term industrial growth.

Emerging Trends in Anti-Deflection Rollers in India

With industries moving towards automation and high-speed production, the demand for advanced roller technologies is also increasing. In India, manufacturers are now focusing on:

- Lightweight Composite Rollers – For reduced inertia and improved machine efficiency.

- Advanced Coating Materials – Offering higher resistance against heat, chemicals, and abrasion.

- Precision Engineering – Enhanced grinding and balancing technologies for near-zero tolerance.

- Customization for Niche Applications – Tailored rollers designed for specific industries like solar film processing, flexible packaging, and specialty papers.

These innovations highlight the importance of partnering with a forward-looking Anti-Deflection Rollers Manufacturer that stays aligned with industry advancements.

Final Thoughts – Choosing the Best Anti-Deflection Rollers in India

The right Anti-Deflection Roller can transform your production line by ensuring consistency, durability, and efficiency. From reducing downtime to improving product quality, these rollers play a vital role in enhancing overall operational performance.

When evaluating options, always consider the build quality, customization possibilities, and the credibility of the Anti-Deflection Rollers Manufacturer in India you are working with. Investing in a trusted partner like Siva Rollers – the Best Anti-Deflection Rollers Manufacturer in Ahmedabad, India ensures you receive rollers engineered for precision, backed by industry expertise, and supported with reliable after-sales service.

For businesses looking to strengthen their operations and gain a competitive edge, choosing the right Anti-Deflection Rollers in India is not just a purchase decision—it’s a step towards long-term success.

FAQs

Anti-Deflection Rollers are specialized industrial rollers designed to resist bending under heavy load, ensuring precision and consistent performance.

They prevent roller bending, maintain uniform pressure, and improve product quality in industries like printing, packaging, textiles, and converting.

Siva Rollers, based in Ahmedabad, is recognized as one of the best Anti-Deflection Rollers Manufacturers in India, known for precision and durability.

They are widely used in printing, packaging, paper, textiles, plastic film converting, and coating industries.

Most deflection rollers are built with high-grade steel, aluminum, or composites like carbon fiber for strength, durability, and lightweight handling.

Check load capacity, coating type, customization options, and manufacturer reputation before buying.

Yes, their durable design and precision engineering reduce wear, downtime, and frequent replacements, saving long-term costs.

Yes, reputed manufacturers offer custom designs in diameter, length, and coating to suit specific industrial needs.

You can buy from trusted suppliers like Siva Rollers – the Best Anti-Deflection Rollers Manufacturer in Ahmedabad, India.