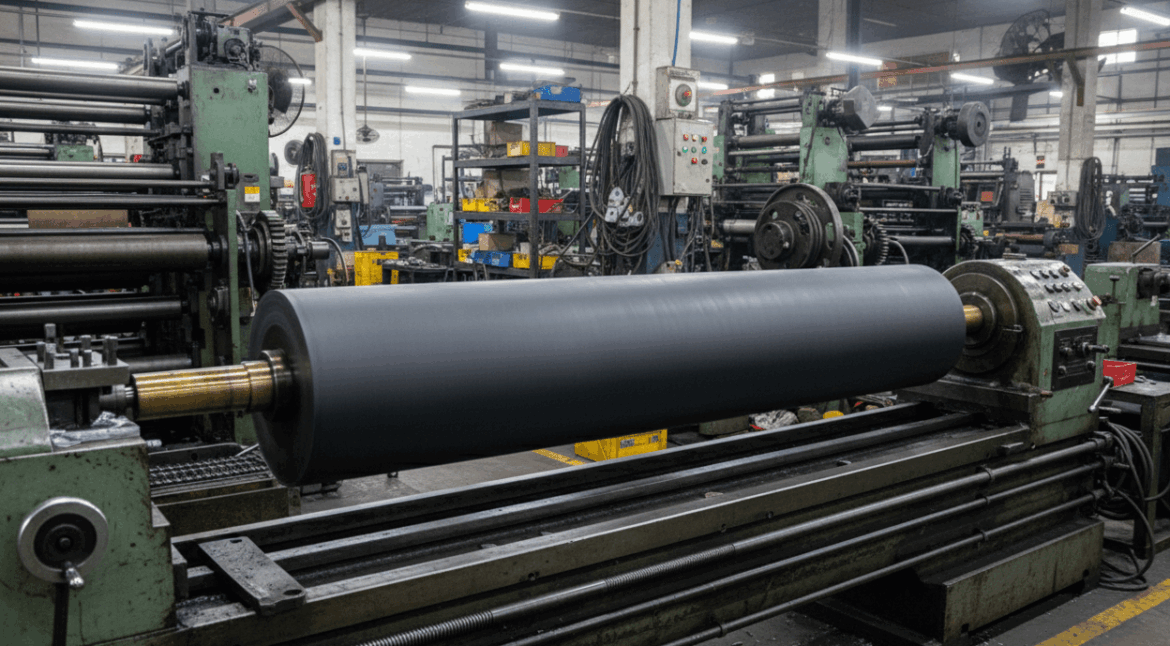

Best Rubber Roller for Offset & Flexo Printing Press – Get Your Free Quotation Today

In high-speed printing, whether you run a large commercial setup or a specialized packaging unit, one component decides your quality, speed, and profit: the Rubber Roller.

Are you an industrial buyer, plant manager, or procurement expert searching for the highest quality rubber roller in india? You know that poor quality rollers cause major headaches. These problems include costly downtime, uneven ink transfer, and plates that wear out too fast.

This detailed guide is for you. We will clearly explain the differences between rollers for Offset and Flexo presses. We will detail the critical concept of printing rubber roller hardness. Above all, we will show you why Siva Rollers best Rubber Roller manufacturer & supplier in India is your ideal partner. We ensure your production line runs perfectly, every time.

Are you ready to secure a reliable, high-performance Rubber Roller that reduces downtime and delivers superior print quality? Let us help you find the perfect solution today.

Why Industrial Buyers Need High-Quality Rubber Rollers

When you invest in a crucial component like an offset printing machine rubber roller or a flexo roller, you are buying more than just a product. You are buying a guarantee of consistent quality and maximum uptime.

Most industrial buyers in India face three common, expensive problems with subpar rubber coated rollers. We solve these problems for you.

The Hidden Cost of Unplanned Downtime

Unplanned downtime represents the biggest cost to your business. When a roller fails—perhaps the rubber coating peels off the core (a sign of poor bonding), or the roller deforms from high pressure and heat—your entire production line stops immediately.

Crucially, every hour your machine stops, you lose revenue and miss important deadlines. Therefore, buyers absolutely need durability and superior bonding. This bonding must withstand 24/7 operation and the heavy demands of modern presses.

2. The Problem of Inconsistent Print Quality

Precision defines high-quality printing. Even a small variation in a roller’s surface, hardness, or roundness (concentricity) leads to defects. For example, you might see “ghosting” (faint images repeating) or uneven color density. This forces costly re-runs and damages your company’s reputation.

Furthermore, buyers require precision measured in microns. They must choose machinery rollers that maintain their surface quality throughout long production cycles.

3. Chemical and Environmental Damage

Inks, washes, and dampening solutions used in printing are chemically aggressive. A poorly chosen printing rubber roller compound will swell or crack very quickly. This is especially true in the fluctuating temperatures and high humidity common in Indian facilities.

Specifically, resistance to the chemicals you use is non-negotiable for roller longevity. A reliable rubber roller manufacturer india must address all these issues with technical expertise. Siva Rollers uses advanced material quality to ensure this resistance.

Offset Printing: Understanding Rubber Roller Hardness and Materials

Offset printing is an intricate process. It relies on a precise balance between ink and water. The rollers in an offset press—often called the heart of the machine—require exact specifications to ensure a perfect image transfer.

1. Core Roller Positions and Required Hardness

The rollers in an offset machine serve specific functions. Consequently, their required printing rubber roller hardness varies widely. Hardness is measured using the Shore A durometer scale, which helps us quantify the roller’s elastic properties.

Inking Form Rollers and Distributor Rollers

- Function: These rollers pick up ink from the ink fountain and deliver it smoothly and evenly to the printing plate. They need high stability and excellent resistance to ink and cleaning solvents.

- Ideal Hardness (Shore A): The standard range for most inking and distributor rollers is between 40 and 60 Shore A. This medium-hard surface guarantees perfect ink pick-up and transfer without harming the delicate printing plate.

- Material Choice: Printers prefer high-grade Nitrile Rubber (NBR) or EPDM compounds. NBR offers strong resistance to oil and conventional offset inks. However, EPDM provides superior resistance when you use UV-curable and specialized inks.

Dampening Rollers (Water Transfer)

- Function: Dampening rollers apply a thin, uniform film of water (dampening solution) to the non-image areas of the plate. This water film repels the ink.

- Ideal Hardness (Shore A): These rollers are much softer, typically in the 20 to 30 Shore A range. In fact, this soft, porous surface ensures a consistent and controlled water application, which is vital for maintaining the critical ink-water balance.

- Material Choice: Manufacturers use specialized, water-loving (hydrophilic) compounds for these roles.

2. The Importance of Precision Grinding

For an offset printing machine rubber roller, the roller must be perfectly concentric (truly round) and dynamically balanced. Any vibration or runout, even if it is tiny, will cause banding or uneven print density.

Therefore, the best rubber roller manufacturer india guarantees that every single roller is ground to extremely tight tolerances. Siva Rollers uses advanced CNC precision machinery for this process, which ensures a flawless surface finish and zero deviation.

Flexo Printing: Demands on Rubber Rollers and Chemical Resistance

Flexographic printing finds wide use in packaging, labels, and flexible films. Conversely, it differs fundamentally from offset printing. Flexo uses fast-drying inks and flexible photopolymer plates, meaning it places unique demands on the rollers.

1. Roller Requirements in a Flexo Press

In Flexo, the roller system focuses on precise ink metering and fast transfer onto non-absorbent materials like plastic films or foil. This requires great durability.

Ink Transfer and Impression Rollers

- Function: The Rubber Roller system works with the Anilox roller (the engraved metering roller) to deliver a very precise and controlled volume of ink to the printing plate. The impression roller then applies pressure to the substrate.

- Ideal Hardness (Shore A): Flexo rollers typically operate in a softer range than many offset rollers, often between 35 and 50 Shore A. Moreover, this softer contact allows the roller to interface smoothly with the flexible plate and the rigid Anilox roller. This guarantees optimal ink release and reduces wear on the expensive plates.

- Material Choice: The inks used in flexo (water-based, solvent-based, or UV) are aggressive and require extreme chemical resistance. Consequently, EPDM is frequently chosen for water-based inks. We often use highly resistant Nitrile (NBR) or tough Polyurethane (PU) for solvent-based or heavy-abrasion applications.

2. The Crucial Role of Chemical Resistance in Flexo

The lifespan of a printing rubber roller in a flexo press depends heavily on its ability to resist cleaning solvents (like Acetates or Alcohols) and the inks. A cheap roller will absorb these chemicals. It will swell, quickly lose its optimal printing rubber roller hardness, and soon become unusable.

Above all, choosing the correct polymer compound is the single most important decision for a flexo operation. Only an experienced rubber roller manufacturer india can provide this level of expertise. You must select a Rubber coated rollers solution that is custom-engineered for your specific ink chemistry.

Why Siva Rollers is the Best Rubber Roller Manufacturer in India

When you select the perfect Rubber Roller for your industrial needs, technical expertise and quality commitment are essential. Siva Rollers has proudly established itself as the Siva Rollers best Rubber Roller manufacturer & supplier in India. Leading printers and converters across the country trust our products.

Our dedication to superior engineering helps you solve the core problems that plague other suppliers:

Advanced Compound Formulation for Longevity

We never use generic rubber. Instead, we formulate every printing rubber roller compound in-house based on your specific application:

- High-End Nitrile (NBR): This material is perfect for high-speed offset inks. It offers excellent resistance to swelling and ensures long life.

- EPDM: This is the ideal choice for water-based and UV-curing flexo systems. It provides superior thermal and chemical stability.

- Polyurethane (PU): We use PU for demanding industrial applications because it offers the highest load-bearing capacity and abrasion resistance.

Therefore, this specialized approach ensures your Rubber Roller maintains its precise printing rubber roller hardness (Shore A) and chemical stability for many years.

2. Guaranteed Bonding: Eliminating Peeling

Poor rubber-to-metal bonding is one of the most common reasons for roller failure. At Siva Rollers, we utilize a multi-stage chemical and mechanical bonding process before vulcanization (curing).

This process creates an unbreakable, single-piece bond between the Rubber coated rollers material and the core. This virtually eliminates the risk of peeling under extreme heat or tension.

3. Micron-Level Precision and Dynamic Balancing

For any high-speed offset printing machine rubber roller or flexo roller, precision remains paramount. All Siva Rollers undergo strict processing steps:

- CNC Grinding: We achieve perfect diameter and concentricity with tolerances often measured in single microns.

- Dynamic Balancing: We dynamically balance every high-speed roller. This guarantees zero vibration at operational speeds, which results in sharp print quality and protects your valuable press machinery from undue stress.

4. Comprehensive Service: Re-rubbering and Customization

In addition, investing in a quality core is smart business. Siva Rollers is not just a manufacturer; we are a full-service rubber roller manufacturer india. We offer expert re-rubberizing services.

We can restore your existing cores by stripping the old, worn coating. Subsequently, we apply a new, precision-engineered Rubber Roller coating. This saves you significant replacement costs while ensuring factory-new performance. Every Rubber Roller we produce is tailored precisely to match your specific press model and application.

Your Next Step: Get Your Free Quotation from Siva Rollers

Choosing the correct Rubber Roller is a strategic business decision. This choice directly impacts your profitability. Whether you run an intricate multi-color offset job or a high-volume flexible packaging line, partnering with the right rubber roller manufacturer india is the key to your success.

Do not let low-quality rubber coated rollers slow down your production or compromise your print quality. Instead, choose the technical superiority and proven reliability that Siva Rollers delivers to clients nationwide.

Siva Rollers is your dedicated rubber roller manufacturer india. We offer end-to-end solutions for all your printing needs.

Take Control of Your Production Quality Today

Are you ready to experience the difference a precision-engineered printing rubber roller makes? Are you tired of inconsistent hardness, poor ink transfer, and peeling rubber?

Contact us today for a Free Quotation and Expert Consultation.

Our technical team will analyse your printing press (Offset or Flexo), your ink system (UV, Solvent, or Water-based), and your required printing rubber roller hardness (Shore A). Therefore, we can recommend the perfect, custom-formulated Rubber Roller solution for you.

Siva Rollers best Rubber Roller manufacturer & supplier in India helps ensure your machine runs smoother, faster, and more profitably.

FAQs

For Offset Printing, inking and distributor rollers usually perform best between 40–60 Shore A hardness using Nitrile (NBR) or EPDM compounds. Dampening rollers require 20–30 Shore A with hydrophilic rubber. This hardness ensures smooth ink transfer and perfect ink–water balance.

Flexo rollers commonly run between 35–50 Shore A so they can work smoothly with photopolymer plates and the Anilox roller. Hardness may vary based on substrate, ink type, and line speed.

Hardness controls ink pick-up, transfer, pressure, and dot sharpness. If hardness is wrong, you will see ghosting, banding, uneven density, and plate damage. Correct hardness guarantees better print clarity and roller life.

Lifespan depends on ink type, cleaning chemicals, roller compound, and press speed. With proper compound and bonding, Siva Rollers are engineered for long-term operation without swelling, peeling, or cracking.

Peeling happens when bonding between core and rubber is weak. Heat, pressure, and chemicals break the layer. Siva Rollers prevents this using multi-stage chemical + mechanical bonding before vulcanization.

Yes. Re-rubberizing is cost-effective. We strip the old coating, reapply a new compound, regrind to microns, and dynamically balance the roller. This restores factory-new performance.

- EPDM is best for water-based and UV inks.

• NBR works for oil-based offset inks.

• PU (Polyurethane) is ideal for high abrasion, high load, and tough industrial applications.

If a roller is not perfectly round, you get vibration, banding, density variation, and mechanical wear. Siva Rollers grinds rollers with CNC machines to micron accuracy for perfect print results.

Factors include ink chemistry, press type (Offset / Flexo), print speed, substrate, required hardness, and load. Siva Rollers provides free technical consultation to recommend the perfect custom roller.

Yes. Siva Rollers offers Free Quotation + expert analysis of press type, inks, hardness, and application to recommend the most accurate roller solution.