Buy Banana Roller for Textile & Packaging Industries – Direct from India Best Manufacturer

In the fast-paced world of textile and packaging industries, precision machinery plays a pivotal role in maintaining product quality and operational efficiency. One such essential component is the Banana Roller, also known as the Bowed Banana Roller or Expander (Bow) Roller. Whether it’s to remove wrinkles, prevent overlapping, or ensure proper web alignment, these rollers are indispensable for various applications.

If you’re in search of high-quality Banana Rollers, buying direct from India’s best manufacturer ensures not only superior product performance but also cost-effectiveness. This blog will guide you through everything you need to know about Banana Rollers and why sourcing them from trusted manufacturers like Siva Rollers, based in Ahmedabad, can significantly benefit your operations.

What Is a Banana Roller?

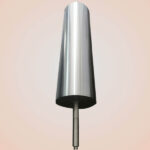

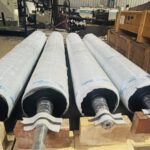

A Banana Roller, often referred to as a Bowed Banana Roller or Expander Roller, is a specially designed industrial roller with a curved or bowed shape. This unique design helps in spreading the web material evenly, preventing wrinkles or creases during the production process. These rollers are commonly used in machinery for textile, packaging, paper, plastic film, and converting industries, where continuous web handling is essential.

The name “Banana Roller” comes from its distinctive arc shape that resembles a banana. The curvature helps apply tension evenly across the width of the material, ensuring that no part of the web is slack or overlapping.

How Banana Roller Work in Textile and Packaging Industries

In the textile industry, web alignment is critical during processes like dyeing, coating, and drying. Bowed Banana Roller help maintain proper fabric alignment by exerting a uniform stretch on the material. This prevents wrinkles, bubbles, or distortions from forming—especially in delicate or synthetic fabrics.

In the packaging industry, where thin films and foils are widely used, maintaining tension and alignment is vital for smooth sealing, printing, and lamination. Here, Expander (Bow) Rollers help flatten the film, removing wrinkles that may otherwise cause quality defects or machine jams.

By integrating Banana Rollers into textile and packaging machines, industries can significantly reduce wastage, improve product aesthetics, and enhance throughput.

Applications of Bowed Banana Roller

Banana Roller find extensive usage across multiple sectors due to their versatility and reliability. Some common applications include:

- Textile processing (knit, woven, and non-woven fabrics)

- Film extrusion and lamination

- Paper and pulp industries

- Plastic and flexible packaging

- Printing and coating lines

- Slitting and rewinding machines

Each application demands specific design variations, which is why choosing the right manufacturer matters when buying Banana Rollers for industrial use.

Materials and Build Quality

The performance of a Banana Roller is directly influenced by its construction material and internal mechanism. The rollers are typically built using:

- Aluminum: Lightweight and corrosion-resistant, ideal for high-speed applications.

- Stainless Steel: Durable and suitable for high-tension environments.

- Rubber-Coated Surfaces: Offer better grip and are often used in sensitive film or fabric handling.

The bending mechanism is carefully calibrated based on the web width, speed, and application. Adjustable end brackets and heavy-duty ball bearings ensure smooth rotation and consistent bow angle throughout operation.

Benefits of Using Banana Roller in Industrial Processes

Implementing Bowed Banana Roller in your textile or packaging line provides a range of operational benefits:

- Wrinkle Removal: Smoothens out any creases or folds in the web material.

- Better Tension Control: Maintains even tension across the web width.

- Improved Productivity: Reduces downtime and improves line speed by avoiding manual corrections.

- Extended Equipment Life: Prevents web misalignment and overlapping that could damage other machinery components.

- Enhanced Product Quality: Produces consistent, defect-free output.

These benefits make Banana Rollers a smart investment for manufacturers focused on quality and efficiency.

Why Buy Banana Roller Direct from India?

India is a global hub for industrial roller manufacturing, offering high-quality, cost-effective solutions. Manufacturers in India combine technical expertise, modern infrastructure, and skilled labor to produce world-class Banana Roller suited for both domestic and international markets.

Buying direct from an Indian manufacturer not only ensures a competitive price but also allows for customization based on your specific machinery requirements. Lead times are shorter, support is localized, and quality is never compromised.

Siva Rollers – Best Banana Roller Manufacturer in Ahmedabad, India

When it comes to sourcing top-grade Banana Roller, Siva Rollers stands out as a leading manufacturer and exporter based in Ahmedabad, Gujarat, India. With 10+ years of experience and a reputation for delivering precision-engineered rollers, Siva Rollers is the go-to choice for industries across India and abroad.

Whether you need a Bowed Banana Roller for textile processing or an Expander Roller for high-speed film packaging, Siva Rollers offers:

- Custom-made Rollers for your machinery

- Superior build quality with long operational life

- Quick delivery timelines

- Competitive pricing

- Trusted client service and technical support

By choosing Siva Rollers, you not only get value for money but also a product that meets the highest standards in industrial engineering.

How to Choose the Right Banana Roller for Your Application

Selecting the right Banana Roller involves understanding your production requirements, such as:

- Web width and material type

- Machine speed

- Roller positioning (entry/exit point)

- Degree of wrinkle removal needed

- Operating temperature and environment

Leading manufacturers like Siva Rollers provide consultation and design support to help you make the right selection, ensuring your roller delivers optimum performance from day one.

Maintenance and Longevity

Banana Roller are built for durability, but periodic checks and preventive maintenance can further extend their lifespan. Regular inspection of:

- Bearings

- Shaft alignment

- Bow angle adjustment mechanism

- Surface coating

…helps maintain their efficiency and prevents unplanned downtime.

High-quality rollers from trusted manufacturers like Siva Rollers often require less frequent servicing and offer superior longevity, making them a cost-effective long-term solution for industrial operations.

Final Thoughts

The use of Banana Roller, including Bowed Banana Roller and Expander (Bow) Roller, is essential for maintaining quality, efficiency, and precision in textile and packaging industries. These rollers not only ensure wrinkle-free operations but also help streamline production lines, reduce manual intervention, and improve the overall quality of the end product.

If you’re planning to buy Banana Roller, sourcing them direct from India’s best manufacturer like Siva Roller in Ahmedabad guarantees you get top-tier quality, tailored solutions, and excellent after-sales support.

Choose smart. Choose efficient. Choose Siva Rollers – India trusted name for Banana Rollers.

FAQs

A Banana Roller, also known as a Bowed Banana Roller or Expander Roller, is used to eliminate wrinkles, align fabric or film, and maintain even tension during processes like coating, printing, slitting, or lamination. It helps improve quality and efficiency in high-speed web handling.

The unique bowed shape of the roller creates a spreading effect across the web material. This stretches the fabric or film outward from the center, which helps flatten out creases and remove any slack or folding.

There is no difference; both terms refer to the same type of roller. Some industries prefer calling it a Banana Roller, while others refer to it as an Expander (Bow) Roller. The function remains the same—wrinkle removal and web alignment.

Yes, Banana Roller can be customized based on machine size, web width, bow angle, and application needs. Trusted manufacturers like Siva Rollers offer tailored designs for textile, paper, and packaging machinery.

Banana Roller are typically made from aluminum, stainless steel, or rubber-coated steel, depending on the application. The roller shaft, surface coating, and internal balancing vary based on load and speed requirements.

Buying directly from Indian manufacturers like Siva Rollers offers cost-effective pricing, customized designs, fast delivery, and international-grade quality. India is known for its precision-engineered industrial rollers.

Industries that frequently use Expander (Bow) Roller include:

- Textile (knit, woven, non-woven)

- Plastic film and flexible packaging

- Paper and converting

- Printing and lamination

With proper use and regular maintenance, a high-quality Banana Roller can last 10+ years. Factors like operating speed, material type, and environmental conditions also affect longevity.

While many Banana Roller are plug-and-play, correct alignment and bow adjustment are crucial. For best results, it's recommended to consult with the manufacturer or have a technician assist with installation, especially for precision applications.

Siva Rollers, located in Ahmedabad, Gujarat, is recognized as one of the best Banana Roller manufacturers in India. They offer custom-engineered Bowed Banana Rollers and Expander Rollers with top-tier quality and dependable support for both domestic and international clients.