How to Identify the Best Rubber Coated Roller Manufacturer in India

Rubber coated rollers are essential components in modern industries ranging from printing and packaging to textiles, steel, and laminating. They play a critical role in maintaining accuracy, ensuring smooth operation, and improving the overall quality of production. Selecting the right rubber roller is not just a technical requirement but also a strategic decision that directly impacts efficiency, durability, and product quality.

For businesses looking to invest wisely, understanding the nuances of roller selection is crucial. This expert guide will walk you through everything you need to know before buying a rubber coated roller in India, ensuring you choose the most reliable solution for your application.

Why Rubber Coated Rollers Matter in Industrial Applications

In any production line, rollers are more than just rotating cylinders. They are responsible for guiding, pressing, coating, laminating, or transferring substrates with precision. A rubber coated roller manufacturer in India designs these rollers with special materials and surface treatments to handle high-pressure environments, resist wear, and maintain dimensional stability.

For example, in the printing industry, rubber rollers ensure proper ink transfer, consistent color, and flawless impressions. In steel and paper manufacturing, rollers withstand heavy loads while preventing slippage and maintaining product uniformity. The quality of the roller directly influences production efficiency, downtime reduction, and the life of other machine components.

Understanding Rubber Coated Rollers

A rubber coated roller typically consists of a metal core (steel or aluminum) covered with a precision-engineered rubber compound. The rubber layer provides the required grip, elasticity, and chemical resistance. Depending on the industry, different coatings—such as natural rubber, nitrile, EPDM, neoprene, or polyurethane—are used.

Key aspects that make rubber rollers indispensable include:

- Friction & Grip: Prevents material slipping and ensures accurate processing.

- Shock Absorption: Protects delicate materials during high-speed operations.

- Chemical & Heat Resistance: Withstands exposure to solvents, inks, and high temperatures.

- Durability: Extends operational life while reducing maintenance costs.

This combination of strength and adaptability makes rubber coated rollers the backbone of various industries in India and worldwide.

Types of Rubber Coated Rollers in India

The application decides the roller type. Some of the widely used variants include:

- Printing Rollers: Critical for offset, flexographic, and gravure printing. They ensure precise ink transfer and consistency. A trusted printing roller manufacturer in India focuses on hardness, surface finish, and resilience to deliver high-quality output.

- Laminating Rollers: Used in the packaging industry to bond films and foils without defects.

- Industrial Feed Rollers: Common in textiles, paper, and steel for guiding and feeding material.

- Anti-Deflection Rollers: Designed to prevent bending or sagging under heavy loads, ideal for wide web processing.

- Heat-Resistant Rollers: Built to withstand extreme conditions in metal and thermal processing industries.

By choosing the right roller type, companies can achieve precision, reduce waste, and ensure seamless production.

Factors to Consider Before Buying a Rubber Roller

Buying a rubber coated roller in India is not just about cost—it’s about long-term performance and ROI. Key factors to evaluate include:

Material Selection

The rubber compound defines the roller’s effectiveness. For printing, softer compounds ensure ink transfer, while in heavy-duty industries, harder rubber or PU coatings are preferred for strength and abrasion resistance.

Roller Hardness (Durometer)

The hardness of the rubber impacts pressure distribution, grip, and durability. A professional rubber roller manufacturer in India tailors hardness to suit industry-specific needs.

Core Construction

The roller core, usually made of steel, aluminum, or composite materials, must be engineered for balance, concentricity, and load-bearing capacity.

Surface Finish

A smooth or textured surface can significantly impact ink or adhesive transfer. For printing rollers, micro-finished surfaces are essential to achieve flawless impressions.

Temperature & Chemical Resistance

In industries involving solvents, heat, or chemicals, rollers must be customized with compounds like EPDM or silicone to prevent degradation.

Manufacturer Expertise

Partnering with a reliable rubber coated roller manufacturer in India ensures technical guidance, customization, and consistent quality.

Why Choose a Trusted Rubber Roller Manufacturer in India

With growing competition, choosing the right supplier is just as important as selecting the roller itself. A trusted manufacturer offers:

- Customization: Every industry requires specific roller properties. Leading suppliers design rollers to meet exact operational needs.

- Precision Engineering: Advanced balancing, grinding, and finishing techniques ensure flawless performance.

- Quality Assurance: Testing for hardness, concentricity, and resistance guarantees durability.

- After-Sales Support: Professional assistance for maintenance, re-coating, and refurbishment.

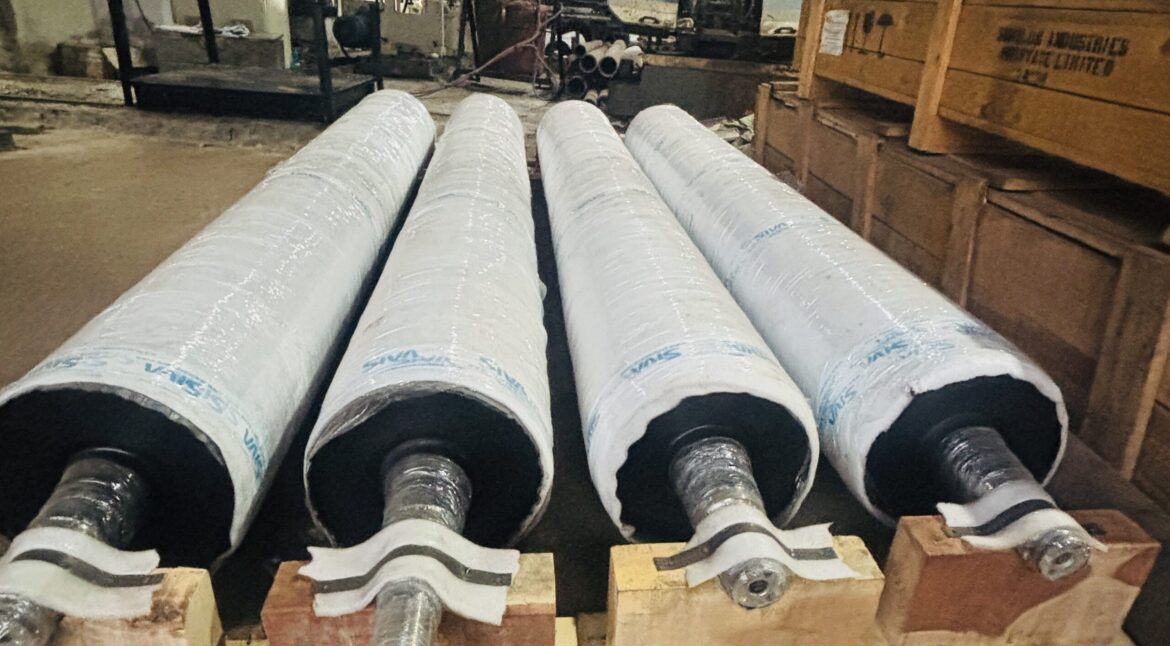

One such trusted name is Siva Rollers – Best Rubber Coated Rollers Manufacturer in Ahmedabad, India, known for delivering world-class rollers for printing, packaging, textiles, steel, and more. Their expertise lies in combining technical innovation with superior raw materials to provide long-lasting solutions for Indian and global markets.

Benefits of Investing in High-Quality Rubber Rollers

Businesses that compromise on roller quality often face downtime, product defects, and frequent replacements. Investing in premium rollers ensures:

- Higher Production Efficiency: Rollers designed with precision run smoothly and reduce machine stoppages.

- Improved Product Quality: Consistent performance guarantees better surface finish, print quality, or lamination strength.

- Extended Lifespan: Durable materials and coatings reduce replacement frequency.

- Cost Savings in the Long Run: While initial costs may be higher, long-term ROI is significantly better.

These benefits make a compelling case for sourcing rollers from reputed suppliers rather than low-cost alternatives.

The Role of Printing Rollers in Modern Industries

Printing remains one of the largest consumers of rubber rollers in India. A printing roller manufacturer in India focuses on delivering rollers that handle different inks, withstand continuous runs, and deliver consistent print quality. From offset printing machines to advanced flexographic systems, rollers are engineered to precise tolerances.

Choosing the right printing roller in India not only ensures better printing results but also reduces wastage of ink and substrates, contributing to sustainable production practices.

Future of Rubber Coated Rollers in India

With India’s industrial sectors growing rapidly, the demand for advanced rollers is also rising. Automation, high-speed production, and sustainability goals are pushing manufacturers to design rollers with:

- Eco-friendly materials.

- Longer service life.

- Compatibility with high-speed, automated machines.

- Custom coatings for advanced applications.

This shift indicates a strong future for the rubber coated roller manufacturer in India who invests in R&D and adopts global manufacturing standards.

Make the Right Choice for Long-Term Performance

Choosing the right rubber coated roller in India is a decision that directly affects your production efficiency, product quality, and overall profitability. From understanding material selection to partnering with a trusted rubber roller manufacturer in India, every step plays a crucial role in achieving operational excellence.

For industries that demand reliability, Siva Rollers – Best Rubber Coated Rollers Manufacturer in Ahmedabad, India stands out as a trusted partner, offering precision-engineered rollers tailored to your exact needs.

By investing in high-quality rollers, businesses secure long-term performance, reduced downtime, and superior output—making it a decision that pays off well into the future.

FAQs

A rubber coated roller is used to grip, guide, press, or transfer materials in industries like printing, packaging, textiles, steel, and laminating.

Consider factors such as roller material, hardness, core construction, surface finish, and resistance to heat or chemicals. A trusted rubber roller manufacturer in India can guide you.

They provide excellent grip, shock absorption, chemical resistance, and durability, making them essential for smooth industrial operations.

Industries like printing, packaging, paper, steel, textiles, laminating, and converting use rubber coated rollers extensively.

All printing rollers are rubber rollers, but not all rubber rollers are printing rollers. Printing rollers are specifically designed for ink transfer in printing machines.

The lifespan depends on usage, load, and environment. High-quality rollers from a professional rubber coated roller manufacturer in India can last several years with proper maintenance.

Yes. Many manufacturers offer re-coating and refurbishing services to extend the life of rubber rollers, making them cost-effective.

Indian manufacturers offer precision engineering, customization, and cost-effective solutions, making them a preferred choice for global buyers.

Siva Rollers – Best Rubber Coated Rollers Manufacturer in Ahmedabad, India is known for precision engineering, premium materials, and tailored solutions for multiple industries.

You can source them from trusted suppliers like Siva Rollers, who specialize in custom-made rollers for printing, packaging, textiles, and more.