Choosing the Right Chrome Coating Roller for Your Machinery

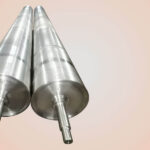

In the world of industrial manufacturing, the choice of rollers plays a pivotal role in operational efficiency, product quality, and machinery longevity. Among various roller types, Chrome Coating Rollers have carved a niche for themselves due to their exceptional durability, smooth surface finish, and corrosion resistance. Choosing the right Chrome Coating Roller is not just a technical decision—it’s a long-term investment in performance, quality, and maintenance cost reduction. Whether you are in packaging, printing, lamination, textile, or converting industries, the right roller can significantly impact your production outcome.

Why Chrome Coating Rollers are Essential in Industrial Machinery

Chrome Coating Rollers are widely used in high-speed and high-precision applications where resistance to abrasion, wear, and chemical corrosion is critical. The chrome layer adds a protective shield to the roller’s core, allowing it to operate in harsh environments with minimal surface degradation. The Hard Chrome Coating Roller is especially suited for heavy-duty applications due to its hardness rating, typically above 60 HRC, making it ideal for scenarios requiring long-term stability and reduced wear.

Furthermore, chrome-coated rollers offer an ultra-smooth surface which is vital in achieving consistent pressure distribution and material handling. Whether your machinery is used for coating, calendaring, embossing, or lamination, investing in the right chrome roller ensures operational continuity and surface perfection.

Understanding the Types of Chrome Coating Rollers

Not all chrome-coated rollers are the same. They differ in terms of base material, chrome thickness, surface finish, hardness, and application focus. The two most common types are:

- Hard Chrome Coating Rollers – Designed for high-wear environments where longevity and hardness are top priorities. These rollers are typically used in steel, plastic, paper, and rubber processing industries.

- Soft Chrome Coating Rollers – Used where some flexibility is necessary, and where the emphasis is on surface protection rather than extreme hardness. These are less common but can be found in specific textile and film applications.

Choosing the right type depends on the material being processed, the machine’s speed, temperature, and load conditions.

Key Features to Look for in a Chrome Coating Roller

When evaluating options, the following parameters are crucial in determining whether a Chrome Coating Roller is right for your needs:

- Hardness and Durability: The roller must withstand constant friction, pressure, and sometimes heat. A good Hard Chrome Coating Roller should have a hardness level of at least 60-65 HRC.

- Surface Finish: A mirror finish or matte finish depending on your application can influence the end-product quality, especially in printing or film coating.

- Coating Thickness: The chrome coating typically ranges from 20 to 100 microns. Thicker coatings provide more wear resistance but may impact roller balance if not applied precisely.

- Core Material: The roller core is usually made of mild steel, stainless steel, or aluminum, depending on load-bearing requirements. A strong core enhances performance under pressure.

- Concentricity and Balancing: Accurate dynamic balancing ensures vibration-free operation, which is critical for high-speed machines.

These factors collectively influence the roller’s performance, machine life, and product quality. Ensure you’re working with a trusted Chrome Coating Roller Manufacturer in India that understands these variables in detail.

Applications Where Chrome Coated Rollers Make a Difference

The demand for Chrome Coating Rollers in India spans a wide range of industries, from precision engineering to bulk manufacturing. Here are a few common applications:

- Printing Industry: Chrome rollers are used in offset, flexo, and gravure printing to provide uniform ink distribution.

- Textile Industry: Used in fabric processing and dyeing, where smooth surface and corrosion resistance are essential.

- Plastic & Film Industry: Helps in lamination, coating, and calendaring processes, ensuring wrinkle-free output and dimensional accuracy.

- Paper & Packaging Industry: Delivers high surface quality in paper coating, embossing, and lamination lines.

- Metal Sheet & Coil Industry: Utilized in processes requiring high-pressure contact and corrosion resistance, such as galvanizing or color coating.

Choosing the wrong roller in these sectors can lead to production downtimes, inconsistent quality, and increased maintenance costs.

Selecting the Right Chrome Coating Roller – Factors to Consider

Selecting a Chrome Coating Roller involves a detailed assessment of several technical and operational parameters. Here’s what you should factor in before making your decision:

- Machine Specifications: Understand your machine’s roller size, speed capacity, and temperature range. Your roller must match or exceed these parameters.

- Material Compatibility: Different materials—like films, fabrics, paper, or metal—interact differently with chrome surfaces. Choose a roller based on the processed substrate.

- Coating Method: Ask the manufacturer about the type of chrome application used (electroplating, thermal spray, etc.) and its adherence strength.

- Roller Balancing: For high-speed machines, even minor imbalances can lead to major disruptions. Ensure your roller is dynamically balanced to reduce vibration.

- Corrosion Resistance: If your process involves chemicals or steam, prioritize high-quality chrome that offers superior corrosion resistance.

Collaborating with a seasoned Chrome Coating Roller Manufacturer in India will ensure you receive detailed technical guidance for customized roller design.

Chrome Coating Roller Price – What You Should Know

Understanding the Chrome Coating Roller Price is essential to align your budget with quality expectations. Prices can vary based on:

- Roller dimensions and design complexity

- Chrome coating thickness and hardness

- Base material used (MS, SS, Aluminum)

- Balancing and surface finish requirements

- Customization or special application needs

Typically, small to mid-sized standard rollers may start from a few thousand INR, while large industrial rollers with specialized requirements can go much higher. Always focus on value over cost—cutting corners on roller quality can cost you more in the long run due to wear, machine damage, or rejected batches.

Why Partner with Siva Rollers?

When it comes to selecting the most reliable Chrome Coating Roller Manufacturer in India, Siva Rollers stands out for its commitment to quality, innovation, and customer satisfaction. Based in Ahmedabad, India, Siva Rollers brings decades of experience in engineering precision rollers tailored for industrial excellence. From Hard Chrome Coating Rollers to customized solutions for niche applications, their rollers are trusted by leading manufacturers across India.

With state-of-the-art infrastructure, in-house quality control, and a dedicated technical support team, Siva Rollers ensures that every product delivered meets international performance benchmarks. Whether you’re upgrading existing machinery or setting up a new line, Siva Rollers is your dependable partner in achieving consistent output and low maintenance.

Choosing a Manufacturer: Checklist for Decision Makers

Before finalizing a Chrome Coating Roller Manufacturer, use this checklist:

- Do they offer custom designs based on your application?

- Can they provide documentation of material specs and hardness?

- Are their rollers dynamically balanced for high-speed operations?

- Do they offer after-sales support or refurbishment?

- Is the price justified by the quality and longevity?

An experienced partner will not only supply the product but also guide you in maintenance, troubleshooting, and upgrading when required.

Final Thoughts

Choosing the right Chrome Coating Roller is a strategic move that influences your machinery’s efficiency, output quality, and total cost of ownership. From coating thickness and material compatibility to balancing and surface finish, each specification matters in high-performance environments. With the rise in demand for Chrome Coating Rollers in India, especially in automated and precision manufacturing units, businesses must align with the right manufacturer who understands the industry’s pulse.

For organizations seeking robust performance and reliable service, Siva Rollers is the go-to name—delivering excellence as a trusted Chrome Coating Roller Manufacturer in Ahmedabad, India. With their extensive product line and commitment to customer satisfaction, they ensure you’re never rolling the dice when it comes to your production line’s performance.

FAQs

A Chrome Coating Roller is an industrial roller that has been coated with a layer of chromium to enhance surface hardness, wear resistance, and corrosion protection. It is widely used in printing, packaging, lamination, and other high-precision manufacturing industries where durability and surface finish are critical.

Hard Chrome Coating Rollers have a thicker and harder layer of chromium, typically exceeding 60 HRC in hardness. This makes them suitable for high-load, high-speed applications with heavy wear and tear. Regular chrome rollers may have thinner coatings and are used in less demanding operations.

Chrome Coating Rollers are used across multiple industries such as:

- Printing and packaging

- Plastic film and lamination

- Paper and pulp processing

- Textile finishing and dyeing

- Steel coil coating and embossing

These rollers ensure smooth surface transfer, corrosion resistance, and dimensional stability.

To choose the right Chrome Coating Roller, consider:

- Your machine’s load and speed requirements

- Type of material being processed

- Required surface finish (mirror, matte, etc.)

- Coating thickness and hardness

- Corrosion or chemical exposure in the environment

Consulting a specialized Chrome Coating Roller Manufacturer in India like Siva Rollers can ensure a perfect match for your application.

The Chrome Coating Roller Price varies based on roller size, material, chrome thickness, surface finish, and customization needs. Prices can range from a few thousand INR for small rollers to much higher for heavy-duty industrial rollers. It’s best to get a customized quote from a trusted manufacturer.

Yes, Chrome Coated Rollers can often be refurbished. The process usually involves stripping the old chrome, re-machining the surface, and reapplying a fresh chrome layer. This extends the roller’s life and reduces replacement costs, making it a cost-effective maintenance strategy.

A high-quality Hard Chrome Coating Roller can last for several years, depending on usage, material contact, and maintenance. In environments with controlled wear and regular cleaning, these rollers can perform reliably over long production cycles without degradation.

Siva Rollers, based in Ahmedabad, India, is considered one of the best Chrome Coating Roller Manufacturers in India. They specialize in hard chrome rollers for printing, lamination, textile, and industrial applications, offering custom-engineered solutions backed by quality assurance and technical support.

Chrome coating provides:

- Increased surface hardness

- Excellent wear resistance

- Corrosion and chemical protection

- Improved surface smoothness

- Extended roller life

It’s crucial for industries where precision, durability, and consistency are essential for output quality.

To maintain your Chrome Coating Roller:

- Clean regularly using non-abrasive solutions

- Avoid impact or sharp tools on the surface

- Schedule periodic inspections for wear or pitting

- Lubricate supporting components to avoid misalignment

- Partner with a supplier who offers roller resurfacing or recoating