Applications of Chrome Coating Roller in Textile, Paper & Plastic Industries

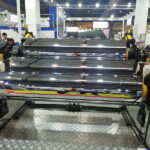

In the modern manufacturing landscape, efficiency, precision, and durability are the backbone of industrial processes. One component that plays a crucial role across industries like textile, paper, and plastic is the Chrome Coating Roller. Known for its high strength, superior wear resistance, and smooth surface finishing, this roller has become indispensable for companies looking to enhance product quality and achieve long-term cost savings.

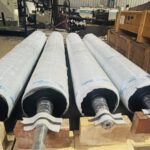

A Chrome Coating Roller is designed by applying a hard chrome layer over a metal base roller. This layer not only increases the roller’s hardness but also provides excellent corrosion resistance, longer service life, and precision surface properties. Whether you call it a Hard Chrome Coating Roller, Hard Chrome Plated Roller, or Chrome Coated Roller, its applications are wide-ranging and vital to industries where precision finishing and durability matter the most.

Importance of Chrome Coating Roller in Industrial Applications

Industries such as textiles, paper, and plastics face common challenges like friction, wear and tear, corrosion, and high production speeds. Traditional rollers often fail to withstand continuous operations, leading to frequent downtime, uneven finishing, and higher maintenance costs.

By introducing a Chrome Coating Roller Manufacturer in India, businesses can benefit from rollers that deliver consistent performance, resist abrasion, and ensure uniform product quality. These rollers provide a perfect combination of strength and smoothness, allowing industries to handle demanding processes with efficiency.

Applications in the Textile Industry

The textile industry relies heavily on rollers for tasks such as calendaring, dyeing, finishing, and laminating fabrics. Here’s how a Hard Chrome Coating Roller enhances textile operations:

- Superior Surface Finish: In calendaring and finishing processes, the chrome-coated surface ensures uniform fabric texture and shine.

- Corrosion Resistance: Textile processes often involve chemicals and dyes. A Hard Chrome Plated Roller resists corrosion, extending service life in harsh working environments.

- Durability in High-Speed Production: Chrome rollers can withstand continuous high-speed fabric processing, minimizing downtime.

- Improved Efficiency: Their smooth surface reduces friction, preventing fabric damage and ensuring high-quality output.

With these benefits, chrome-coated rollers have become a standard in textile finishing plants across India and globally.

Applications in the Paper Industry

Paper manufacturing demands precision, especially in calendering, coating, and printing processes. A Chrome Coated Roller is a trusted solution in paper mills because:

- High Precision in Calendering: Ensures smoothness and uniform thickness of paper sheets.

- Resistance to Wear and Tear: Paper processing involves constant friction. The hard chrome layer prevents early wear, guaranteeing long-lasting performance.

- Gloss and Surface Quality: For coated and specialty papers, chrome rollers enhance the glossy finish and printability.

- Reduced Maintenance: Chrome coating reduces sticking issues during coating and printing, making the process more efficient.

Whether it’s for producing high-quality printing paper or packaging material, Hard Chrome Coating Rollers ensure consistency in output while reducing operational challenges.

Applications in the Plastic Industry

The plastic industry also benefits greatly from Chrome Coating Rollers in processes like film extrusion, laminating, and calendaring. Their role is particularly critical because plastic processing requires precise temperature control and a high-quality surface finish.

- Smooth Film Production: In extrusion and calendaring, chrome rollers provide an even surface, ensuring defect-free films and sheets.

- Thermal Conductivity: Hard chrome-coated surfaces aid in effective temperature control, essential for plastic processing.

- Resistance to Sticky Surfaces: Plastic materials tend to stick to rollers. Chrome’s smooth finish prevents adhesion, ensuring uninterrupted production.

- Enhanced Durability: These rollers withstand continuous high-pressure operations common in plastic sheet and film manufacturing.

As the demand for high-quality plastic products grows, manufacturers increasingly rely on Hard Chrome Plated Rollers to meet stringent production standards.

Benefits of Choosing a Trusted Chrome Coating Roller Manufacturer

Selecting the right Chrome Coating Roller Manufacturer in India is as important as the rollers themselves. A high-quality manufacturer ensures precision engineering, advanced chrome plating technology, and strict quality checks. This results in rollers that:

- Deliver consistent performance across industries.

- Last longer, reducing replacement frequency.

- Support faster production with minimal downtime.

- Meet international quality standards for surface finish and durability.

One such reliable partner is Siva Rollers, widely recognized as the Best Chrome Coating Roller Manufacturer in Ahmedabad, India. With expertise in designing durable and high-performance industrial rollers, Siva Rollers caters to diverse sectors with solutions that combine innovation and quality.

Why Industries Prefer Chrome Coating Rollers

The preference for Chrome Coated Rollers across textile, paper, and plastic industries comes down to a few undeniable factors:

- Strength and Longevity: Hard chrome plating significantly increases roller life.

- Smooth Surface Quality: Essential for precision finishing applications.

- Resistance to Chemicals and Corrosion: Ideal for industries exposed to harsh chemicals.

- Low Maintenance Costs: Longer service life means fewer replacements and reduced downtime.

These advantages translate into higher productivity, better product quality, and long-term cost savings.

Final Thoughts

The Chrome Coating Roller is more than just an industrial component—it is a performance enabler for textile, paper, and plastic industries. Its applications in calendaring, finishing, coating, and laminating processes make it indispensable for modern manufacturing. Whether you require the precision of a Hard Chrome Coating Roller, the durability of a Hard Chrome Plated Roller, or the efficiency of a Chrome Coated Roller, choosing the right manufacturer ensures optimal results.

If you are looking for trusted quality, Siva Rollers stands out as the Best Chrome Coating Roller Manufacturer in Ahmedabad, India, delivering engineered rollers that exceed industry standards. By investing in chrome-coated rollers, industries can achieve superior product quality, reduced downtime, and long-term operational efficiency.

FAQs

A Chrome Coating Roller is a precision-engineered roller with a layer of hard chrome plating on its surface. It is used in textile, paper, and plastic industries to improve durability, ensure smooth finishing, resist corrosion, and enhance overall production quality.

Both terms refer to the same component. A Hard Chrome Coating Roller or Hard Chrome Plated Roller is a roller with a hardened chrome layer. This layer provides wear resistance, higher surface hardness, and smooth finishing, making it suitable for demanding industrial applications.

In the textile industry, a Chrome Coated Roller improves fabric calendaring, enhances surface smoothness, resists chemical corrosion during dyeing, and ensures uniform finishing. It also reduces downtime by providing long service life in high-speed production.

Paper mills use Hard Chrome Coating Rollers for calendering, coating, and printing because they deliver consistent thickness, improve surface gloss, and resist friction wear. This ensures high-quality printing paper, packaging material, and specialty paper production.

In the plastic industry, Chrome Coated Rollers are essential for film extrusion, laminating, and calendaring. Their smooth finish prevents material sticking, ensures defect-free plastic films, and supports precise temperature control during production.

In the plastic industry, Chrome Coated Rollers are essential for film extrusion, laminating, and calendaring. Their smooth finish prevents material sticking, ensures defect-free plastic films, and supports precise temperature control during production.

The lifespan depends on usage and maintenance, but a Hard Chrome Plated Roller generally lasts significantly longer than standard rollers. With proper handling and maintenance, it can perform efficiently for several years, reducing replacement costs.

Working with a reliable Chrome Coating Roller Manufacturer in India ensures access to advanced chrome plating technology, international quality standards, cost-effective pricing, and quick delivery. Indian manufacturers like Siva Rollers are known for precision engineering and durability.

Yes. A Hard Chrome Coating Roller provides excellent resistance to chemicals, moisture, and high temperatures. This makes it suitable for industries where rollers are exposed to dyes, adhesives, and heat during production processes.

Maintenance involves regular cleaning, avoiding abrasive materials, and ensuring proper lubrication of roller assemblies. By partnering with a trusted Chrome Coating Roller Manufacturer in India, you can also get technical support and servicing guidelines for maximum efficiency.

Siva Rollers is recognized as the Best Chrome Coating Roller Manufacturer in Ahmedabad, India, offering high-quality Hard Chrome Coating Rollers, Hard Chrome Plated Rollers, and Chrome Coated Rollers designed for textile, paper, and plastic industries. Their products combine durability, precision, and cost-effectiveness.