Chrome Rollers for Paper Industry – Benefits & Usage

In the competitive and quality-driven world of the paper manufacturing industry, the equipment used in the production process plays a crucial role in determining efficiency, product quality, and operational cost. Among these critical components, Chrome Roller stand out as indispensable tools for paper processing plants. Known for their durability, surface finish, and resistance to wear and tear, these rollers are now an industry standard across global paper mills.

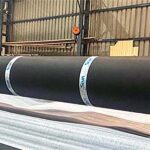

Chrome rollers are specially engineered industrial roller coated with a layer of chromium, enhancing their strength and resistance to corrosion and abrasion. This coating ensures that the roller can perform consistently under high pressure, temperature fluctuations, and demanding production cycles common in paper manufacturing. As the paper web passes through multiple rollers during the calendaring, coating, and drying stages, the surface precision of chrome-coated rollers helps maintain paper quality and finish.

Enhanced Surface Hardness and Durability

One of the key benefits of using Hard Chrome Plated Roller in paper manufacturing is their exceptional surface hardness. The chrome layer, typically electroplated, creates a dense, wear-resistant coating that significantly extends the life of the roller. This resistance to surface damage is vital in paper production, where continuous operation and contact with chemicals or paper dust can degrade lesser materials. Chrome-coated rollers offer a longer service life and reduce the frequency of replacement, which in turn decreases operational downtime and maintenance costs.

Excellent Corrosion Resistance

Paper manufacturing often involves exposure to high moisture content, steam, and chemical additives. This environment can corrode and degrade conventional rollers quickly. However, Chrome Coated Roller provide excellent protection against corrosion due to the chemically stable nature of chromium. The coating acts as a barrier, preventing the metal beneath from oxidizing or reacting with harsh substances. This makes chrome rollers highly suitable for various sections of the paper plant, including sizing presses, wet ends, and drying sections.

Superior Surface Finish and Web Control

The smooth and uniform surface finish of Chrome Roller contributes significantly to the quality of the final paper product. A smoother roller surface ensures consistent contact with the paper web, reducing friction, breakage, and misalignment. This helps in maintaining web tension, proper sheet formation, and accurate thickness during the calendaring or finishing processes. In high-speed machines, where web stability is a concern, hard chrome rollers provide the needed consistency and reliability.

High Load-Bearing Capacity

The ability to withstand heavy loads is another advantage of using industrial roller with hard chrome plating in the paper industry. Paper production involves the movement of large webs at high speeds and the application of pressure during pressing and drying. Chrome rollers are capable of handling such stresses without deforming or losing their dimensional accuracy. The rigidity and strength of chrome-coated rollers make them ideal for use in calendaring stacks and press sections where load-bearing is crucial.

Heat Resistance for High-Temperature Processes

Certain parts of the paper production process, such as drying, involve elevated temperatures that can challenge the performance of regular rollers. Chrome-coated surfaces exhibit strong thermal resistance, allowing them to maintain their structural integrity and surface finish even under sustained heat exposure. Their stability under high temperatures contributes to their longevity and helps maintain consistent paper quality over long production runs.

Easy Maintenance and Polishing

Maintaining a smooth and defect-free surface on the roller is critical in the paper industry. Hard Chrome Plated Roller are easier to maintain and re-polish compared to other materials. Over time, if the surface loses its gloss or smoothness due to continuous usage, it can be easily re-ground and re-polished without removing the chrome layer completely. This reusability makes chrome rollers an economically smart investment for large-scale paper production facilities.

Cost-Efficiency Over Time

While the initial investment in chrome-coated roller might be higher than standard rollers, their long-term benefits outweigh the cost. Extended service life, lower maintenance needs, and reduced downtime make these rollers highly cost-efficient. Their reliability ensures continuous production, which is essential for meeting market demands and maintaining profitability in the competitive paper industry.

Compatibility with Various Paper Grades

From writing and printing papers to packaging board and tissue products, chrome rollers are compatible with a wide range of paper types. Their smooth surface and hardness allow for consistent calendaring and coating, which are critical in determining paper gloss, thickness, and smoothness. Paper mills producing premium or high-gloss paper particularly benefit from the precision of hard chrome rollers.

Environmentally Friendly Recoating

Chrome rollers can be recoated instead of replaced, reducing waste and environmental impact. The recoating process involves stripping the old chrome layer, re-plating, and polishing the surface. This sustainable approach supports the paper industry’s growing commitment to environmentally responsible manufacturing practices. It also lowers raw material consumption and contributes to the circular economy model.

Trusted by Leading Paper Mills

Due to their dependable performance and lasting quality, Chrome Roller have earned the trust of leading paper mills in India and across the globe. Their consistent performance has made them a core component in modern, automated paper machines. Whether it’s a large-scale manufacturer or a specialty paper producer, chrome-coated rollers have become a standard for achieving high efficiency and superior product output.

Why Choose Siva Rollers – Best Chrome Roller Manufacturer in Ahmedabad, India

When it comes to sourcing high-quality chrome roller for the paper industry, Siva Rollers is a name that stands out. Based in Ahmedabad, India, Siva Rollers is a trusted manufacturer specializing in precision-engineered chrome-coated roller, hard chrome plated roller, and industrial roller for various paper applications. Their rollers are manufactured using the latest plating technology and quality control systems to ensure exceptional performance and durability. Siva Rollers understands the specific needs of paper manufacturers and provides custom roller solutions tailored to fit unique machine requirements. If you are looking for reliability, consistency, and superior build quality, Siva Rollers is your ideal partner in chrome roller supply.