Chrome Transfer Replacement Rollers: When to Replace, Where to Buy & How to Avoid Downtime

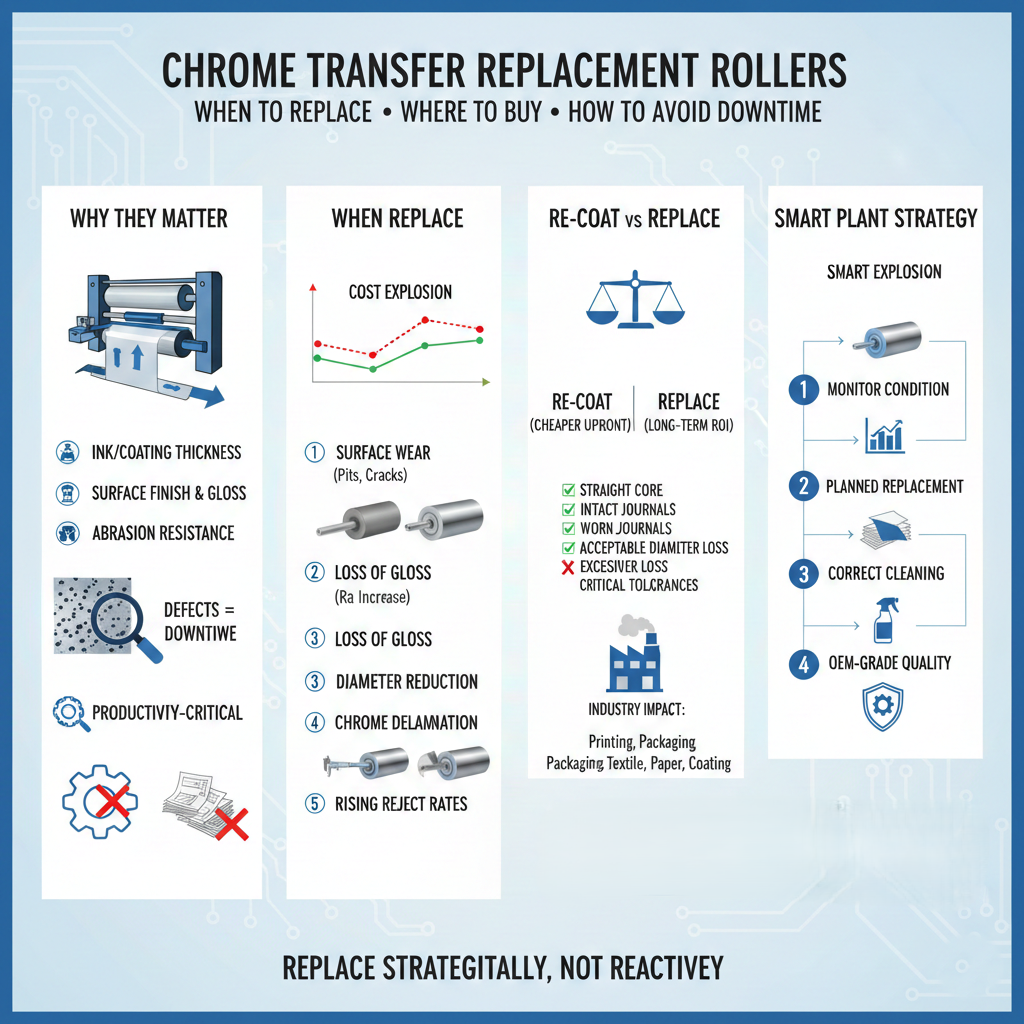

In high-speed industrial production, the Chrome Coating Roller is one of those quiet workhorses nobody notices—until something goes wrong. In printing presses, coating lines, laminators, textile calenders, and flexible packaging machines, chrome transfer rollers directly control surface finish, coating uniformity, ink transfer, and web handling stability. When these rollers wear out or drift out of tolerance, defects multiply, downtime rises, and production costs quietly explode.

Chrome transfer replacement rollers should be replaced when you notice surface wear such as pitting, scratches, uneven chrome thickness, vibration during operation, or inconsistent coating and print quality. Delayed replacement can lead to frequent machine stoppages, higher rejection rates, and costly unplanned downtime. Industrial manufacturers prefer OEM-grade chrome transfer rollers with precise hard chrome coating, dynamic balancing, and tight dimensional tolerances to maintain consistent output. Choosing a reliable manufacturer like Siva Rollers, known for high-performance chrome coating rollers, helps extend roller life, improve surface finish, and reduce long-term maintenance costs.

That is why Chrome Transfer Replacement Rollers are not just maintenance parts. They are productivity-critical components that protect output quality, machine health, and delivery commitments.

Why Chrome Transfer Rollers Matter More Than Most Plants Admit

Chrome transfer rollers sit at the intersection of mechanical precision and surface chemistry. Their hard chrome layer controls:

- Ink or coating film thickness

- Release behavior and wetting

- Friction and slip control

- Surface smoothness and gloss

- Resistance to abrasion, chemicals, and heat

In printing and coating operations, even micron-level surface damage or diameter deviation can cause visible defects—streaking, banding, coating voids, ghosting, or uneven gloss.

In textile processing and paper coating lines, worn chrome rollers can destabilize web tension, distort nip pressure, and reduce calendaring consistency.

That is why Industrial Chrome Coating Rollers are engineered as precision components, not generic steel shafts with chrome slapped on top.

When to Replace Chrome Transfer Rollers (Before They Cost You a Fortune)

Most plants replace rollers far too late. They wait until defects become intolerable or breakdowns force emergency shutdowns. Smart maintenance teams track roller condition and replace at the economically optimal point.

Here are the most reliable indicators for when to replace chrome rollers:

1) Surface Wear, Pitting, or Micro-Cracks

Hard chrome is durable, but it is not immortal. Over time, abrasive coatings, pigments, fillers, and cleaning chemicals create micro-pits and hairline cracks. These defects hold ink or coating, causing streaks and film irregularities.

2) Loss of Surface Finish (Ra Increase)

When the roller’s surface roughness exceeds design tolerance, coating transfer becomes unstable. Gloss drops. Coating weight fluctuates. Cleaning frequency increases.

3) Diameter Reduction Beyond Tolerance

Repeated polishing, grinding, or re-coating slowly reduces roller diameter. Once the diameter drifts outside machine tolerance, nip pressure, speed synchronization, and coating thickness control all suffer.

4) Chrome Delamination or Blistering

Poor adhesion, thermal cycling, or chemical attack can cause chrome layers to blister or peel. At that point, re-coating may not be structurally safe.

5) Rising Reject Rates and Downtime

If print defects, coating inconsistencies, or web handling issues rise without other process changes, worn chrome transfer rollers are often the hidden culprit.

These are classic chrome roller wear signs that indicate replacement or re-coating is no longer optional.

Re-Coating vs Replacement: A Practical Decision Framework

One of the most common buyer questions is:

Industrial roller re-coating vs replacement — which makes more sense?

Re-coating is often attractive because it appears cheaper upfront. But it is not always the correct technical or economic choice.

Re-Chroming Extends Life Further

- The roller core is perfectly straight and crack-free

- Journal ends and bearing seats are within tolerance

- Diameter loss after grinding remains acceptable

- The roller has not undergone multiple past re-coatings

Full replacement is smarter when:

- The core has fatigue cracks or distortion

- Bearing journals are worn or misaligned

- Excessive diameter loss has occurred

- The chrome layer repeatedly fails prematurely

- Tight runout tolerances are critical for your application

For high-speed printing, flexible packaging, and precision coating lines, hard chrome roller replacement often delivers better long-term ROI than repeated re-coating cycles.

Industry-Specific Impact of Worn Chrome Transfer Rollers

Different industries experience different pain points from degraded rollers:

Printing & Packaging

- Streaking and ghosting

- Inconsistent ink transfer

- Plate wear acceleration

- Reduced print sharpness

Paper & Pulp

- Uneven coating thickness

- Surface mottle

- Poor calendaring uniformity

- Web tracking instability

Textile Processing

- Dye streaks

- Uneven finishing

- Fabric tension irregularities

Lamination & Coating Lines

- Film thickness variation

- Adhesive voids

- Surface defects

- Poor layer bonding

Flexible Packaging

- Visual defects

- Seal failures

- Barrier coating inconsistency

In all these cases, worn rollers silently drain yield, increase scrap, and damage brand reputation.

How Smart Plants Prevent Roller-Related Downtime

Downtime prevention is not luck. It is a maintenance strategy.

1) Condition-Based Monitoring

Track roller surface roughness, diameter, and runout during scheduled shutdowns. Trend the data. Replace before tolerance limits are crossed.

2) Planned Replacement Cycles

Instead of waiting for failure, maintain a spare set of Replacement Chrome Rollers ready for quick changeover.

3) Correct Cleaning Chemistry

Aggressive solvents and alkaline cleaners accelerate chrome degradation. Use coating-compatible cleaners.

4) Proper Storage and Handling

Improper storage causes corrosion and mechanical damage before rollers even reach the machine.

5) OEM-Grade Manufacturing Standards

Low-cost chrome rollers with poor adhesion, uneven plating thickness, or substandard metallurgy fail prematurely.

This is where the right Chrome Transfer Roller Manufacturer becomes a strategic supplier, not a commodity vendor.

What to Look for in a Chrome Transfer Roller Manufacturer

Not all chrome rollers are created equal. When sourcing Industrial Chrome Coating Rollers, buyers should evaluate:

- Core metallurgy and heat treatment

- Chrome plating thickness uniformity

- Adhesion strength and crack resistance

- Final grinding and polishing accuracy

- Runout, concentricity, and straightness

- Balancing quality for high-speed lines

- Application-specific surface finish control

A credible Chrome Roller Supplier in India should provide documented tolerances, process controls, and application engineering support—not just a price quote.

Siva Rollers – Best Hard Chrome Plated Rollers Manufacturer & Supplier in India

Siva Rollers is widely recognized as a Best Chrome Coating Roller Manufacturer in India, supplying precision-engineered chrome transfer rollers to printing, packaging, textile, paper, and coating industries.

Rather than selling generic products, Siva Rollers focuses on:

- OEM-grade chrome coating processes

- Application-specific surface finishes

- Tight dimensional tolerances

- High adhesion hard chrome layers

- Long service life under aggressive operating conditions

Their Chrome Transfer Replacement Rollers are designed as direct-fit, performance-matched alternatives to original machine rollers—minimising installation risk and startup issues.

For plants struggling with frequent roller failures, coating inconsistencies, or rising downtime, Siva Rollers positions itself as a technical partner, offering:

- Custom replacement rollers

- Technical consultation for roller selection

- Application engineering support

- Re-coating and lifecycle optimization advice

This expertise-driven approach helps plants reduce downtime and improve output quality, not just replace parts.

Where to Buy Chrome Transfer Replacement Rollers With out Regret

Avoid sourcing chrome rollers purely on price. The cheapest roller often becomes the most expensive one once downtime, scrap, and repeat replacements are factored in.

The right supplier should offer:

- OEM-grade chrome coating

- Proven industry references

- Customization capability

- Quality documentation

- Post-sale technical support

A specialized Chrome Transfer Roller Manufacturer like Siva Rollers offers better long-term value than general-purpose job shops or trading companies.

Final Takeaway: Replace Strategically, Not Reactively

Chrome transfer rollers are not consumables. They are precision assets.

Replacing them too late destroys quality. Replacing them too early wastes capital. Replacing them poorly creates endless downtime loops.

The smartest industrial buyers track roller condition, source OEM-grade replacements, and work with manufacturers who understand both metallurgy and machine behaviour.

That is why companies across printing, packaging, textile, paper, and coating sectors increasingly rely on technically competent suppliers like Siva Rollers – Best Chrome Coating Roller Manufacturer in India for long-life, application-optimized Chrome Transfer Replacement Rollers.

In high-speed production, reliability is not optional. It is engineered—one roller at a time.

CONTACT US

FAQs

You should choose full replacement over re-coating if the roller core has fatigue cracks, the bearing journals are worn/misaligned, or if the roller has undergone excessive diameter loss from previous grinding. Replacement is also recommended for high-speed lines where tight runout tolerances are critical for production quality.

The five primary indicators of failure are:

- Surface Defects: Pitting, micro-cracks, or scratches.

- Reduced Finish: An increase in surface roughness (Ra) causing loss of gloss.

- Diameter Loss: Wear that falls outside the machine’s design tolerance.

- Chrome Delamination: Visible blistering or peeling of the chrome layer.

- Increased Rejects: Rising instances of ghosting, streaking, or uneven coating.

Degraded chrome rollers lead to inconsistent ink transfer, streaking, and ghosting. In flexible packaging, they can cause visual defects, seal failures, and inconsistent barrier coatings, which ultimately increase scrap rates and downtime.

Yes. Using aggressive solvents or high-alkaline cleaners can accelerate the degradation of the hard chrome layer. To prevent premature wear, maintenance teams should use coating-compatible cleaners and follow OEM-recommended cleaning protocols.

Surface roughness (Ra) determines coating uniformity and release behavior. When the Ra value increases beyond tolerance due to wear, it causes unstable coating transfer, fluctuating coating weights, and requires more frequent cleaning cycles.

Siva Rollers is recognized as a leading manufacturer in India, specializing in precision-engineered chrome transfer rollers. They provide direct-fit replacements with application-specific surface finishes for industries including printing, textile, paper, and packaging.

In printing operations, the first signs of wear usually appear as visible streaks, "ghosting" of images, or inconsistent ink density. Physically, you may notice fine scratches (often caused by doctor blade pressure), pitting, or a "matte" appearance in high-wear areas. If the chrome begins to peel (delaminate), it will leave small voids that hold excess ink, leading to recurring print defects that cannot be fixed by adjusting press settings.

Re-coating is typically 40-60% cheaper than a full replacement upfront. However, replacement is the more cost-effective long-term choice if the roller core has fatigue cracks, if the diameter has already been reduced multiple times, or if the bearing journals are worn. For high-precision applications, the "hidden cost" of a re-coated roller failing prematurely often exceeds the price of a new OEM-grade replacement.

To extend roller life, implement these four maintenance steps:

- Use Compatible Cleaners: Avoid high-alkaline or abrasive chemicals that "eat" the chrome.

- Optimize Doctor Blade Pressure: Excessive pressure is the #1 cause of premature chrome wear and scratching.

- Filter Your Inks/Coatings: Use magnets and fine filters to remove metal slivers or contaminants that act as abrasives.

- Monitor Alignment: Misaligned rollers cause uneven pressure distribution, leading to localized "flat spots" or rapid wear on one end.

Chrome peeling is usually caused by poor substrate preparation—specifically residual oils or oxides left on the steel before plating. Other common causes include thermal shock (rapidly heating or cooling the roller), hydrogen embrittlement during the plating process, or corrosion "under-creeping" where chemicals penetrate micro-cracks in the chrome and eat the base metal underneath.