Complete Guide to Buying Rubber Roller Online in India

Rubber rollers are critical components used across multiple industries — from printing and packaging to textiles, steel, paper, and plastics. Their role in ensuring smooth operations, uniform coating, precise material handling, and efficient production is irreplaceable. With the rise of e-commerce and industrial procurement platforms, many businesses now prefer to buy rubber rollers online in India for convenience, speed, and better customization. However, buying the right rubber roller online requires careful attention to quality, specifications, material type, and vendor credibility.

Understanding the Role of Rubber Roller

A rubber roller is a cylindrical component coated with rubber or elastomeric material and used to convey, press, spread, or print on various materials. These rollers function under different conditions — high temperatures, chemicals, heavy load, and continuous rotation — which means selecting the right type ensures both product quality and operational efficiency.

Whether it’s a rubber coated roller for lamination machines or a printing rubber roller for offset presses, each has its unique design and coating based on application requirements. That’s why choosing the right roller involves understanding the application, surface finish, hardness (durometer), and type of rubber used.

Types of Rubber Roller Available Online

When browsing online platforms or contacting rubber roller manufacturers, you’ll notice a range of rollers classified based on coating material and industrial use. Common types include:

- Printing Rubber Roller: Used in printing presses and label machines, requiring precise ink transfer and resistance to solvents.

- Rubber Coated Roller: These are general-purpose rollers used for laminating, guiding, spreading, and coating processes in textiles, packaging, paper, and other industries.

- Ebonite Rollers: Hard rubber-coated rollers suitable for high-pressure applications.

- PU (Polyurethane) Roller: Known for abrasion resistance, widely used in high-speed operations.

- Silicone Rubber Roller: Preferred in applications involving high temperatures and chemical exposure.

Each type varies in composition, resilience, load capacity, and thermal resistance. Buying online gives the advantage of comparing different specifications and finding rollers tailored to your equipment.

Factors to Consider Before Buying Rubber Roller Online

Before placing an order online, it’s essential to review certain technical and practical aspects:

- Application Fitment: The first consideration should be the intended use of the roller. A printing rubber roller differs from a roller used for packaging or lamination. Understanding your industry-specific requirements helps narrow down the options.

- Material Composition: Rubber coatings come in various types — natural rubber, nitrile, EPDM, neoprene, silicone, polyurethane, etc. The choice depends on whether you need chemical resistance, heat endurance, or abrasion resistance. For example, nitrile is great for oil resistance, while EPDM works better with steam and water.

- Hardness (Durometer): This determines the flexibility or stiffness of the roller. A soft roller (around 20-40 Shore A) may be ideal for coating applications, whereas a harder roller (above 70 Shore A) suits heavy-load operations.

- Core Material: Most rollers have cores made of steel, aluminum, or other alloys. A strong core ensures stability during rotation and high-speed processes.

- Roller Dimensions: Be sure to measure and confirm the roller diameter, length, face width, and shaft dimensions. Most reliable rubber roller manufacturers offer customization based on your machinery model.

- Load and Speed Capacity: Always check the maximum operational load and speed to avoid breakdowns or misalignment.

- Coating Thickness and Surface Finish: For precision work, such as in printing or converting industries, surface smoothness and even coating thickness are critical.

Advantages of Buying Rubber Roller Online in India

With India’s booming industrial sector and the growth of online B2B platforms, sourcing rubber roller digitally has become more accessible and efficient. Here’s why more businesses now prefer buying online:

- Convenient Comparison: Buyers can compare different types of rubber coated roller from various manufacturers without the need to visit multiple vendors physically.

- Access to Customization: Many leading rubber roller manufacturers like Siva Rollers offer direct online customization and consultation, allowing you to specify your requirements and get tailored solutions.

- Faster Lead Times: Online ordering often ensures quicker production and delivery cycles, especially if you work with manufacturers based in India’s industrial hubs like Ahmedabad, Mumbai, or Coimbatore.

- Quality Assurance and Certifications: Reputed online suppliers display their quality certifications, client testimonials, and technical sheets. This helps businesses make informed decisions.

- Better Reach to Trusted Manufacturers: Buying online directly connects you with original manufacturers like Siva Rollers, reducing the need for intermediaries and ensuring fair pricing and better after-sales support.

Why Choose Siva Rollers – Best Rubber Roller Manufacturer in Ahmedabad, India

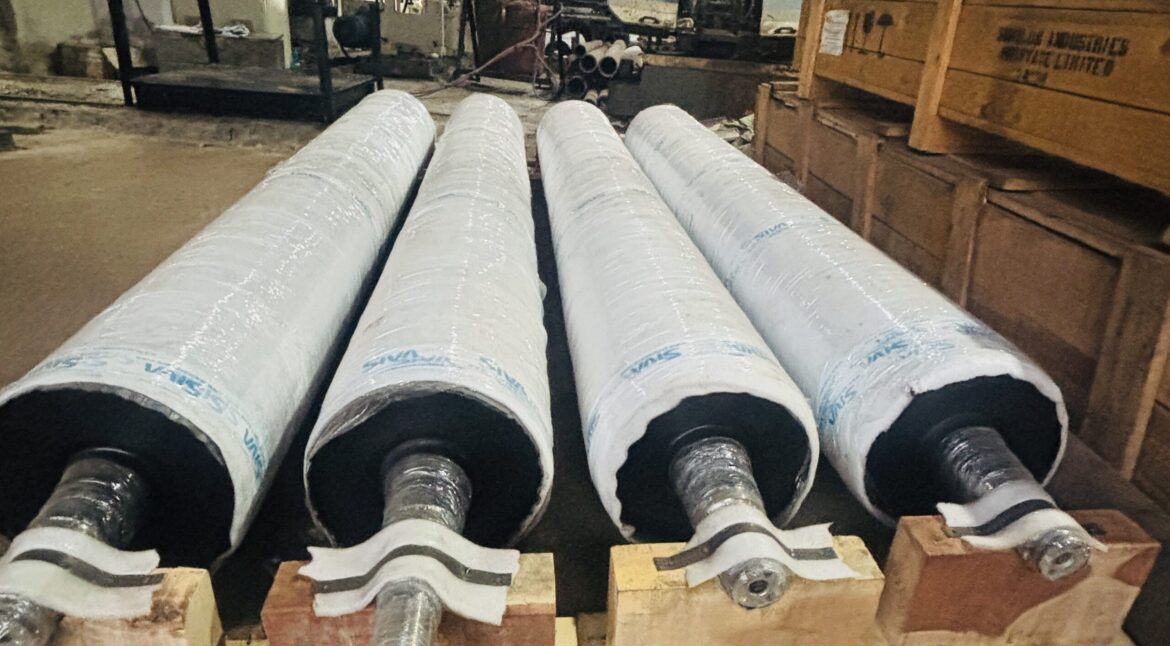

When buying online, it’s important to choose a trusted brand that offers quality, reliability, and customization. Siva Rollers, headquartered in Ahmedabad, Gujarat, stands out as one of India’s most reputed rubber roller manufacturers. Known for delivering rubber rollers to diverse sectors including textiles, printing, packaging, steel, and converting industries, Siva Rollers uses advanced technology and in-house testing to ensure world-class standards.

Their product portfolio includes rubber coated rollers, printing rubber rollers, PU rollers, banana rollers, and custom-engineered industrial rollers. Siva Rollers offers nationwide delivery, excellent customer support, and ensures every product passes through rigorous quality checks before dispatch.

If you’re looking to buy online, Siva Rollers offers a smooth quotation and ordering process through their website and direct business channels.

How to Ensure a Safe and Reliable Online Purchase

As industrial procurement moves online, it’s important to ensure you’re buying from a verified and established source. Here’s how to make your purchase process more secure and effective:

- Always check for proper contact details, factory location, and company registration.

- Look for case studies, reviews, or client feedback on their website or B2B directories.

- Ask for technical datasheets, load-bearing charts, or previous client references.

- Avoid platforms that list third-party sellers without any manufacturer backing.

- Request video inspection or sample testing if possible for large quantity orders.

Future of Online Rubber Roller Procurement in India

With the Indian industrial sector embracing automation and digital procurement, the trend of ordering rubber rollers online is only expected to grow. From SMEs to large OEMs, businesses now prioritize speed, customization, and traceability. Modern rubber roller manufacturers are increasingly investing in digital platforms to streamline ordering, track dispatches, and offer support virtually.

This shift also helps in reducing downtime, enabling easy replacement sourcing, and ensuring consistent machine performance — all of which are vital in competitive production environments.

Final Thoughts

Buying rubber rollers online in India is a smart move — but only when done with careful consideration. By understanding your specific application, selecting the right material and hardness, and partnering with a reputed rubber roller manufacturer, you can enhance your machine’s efficiency and ensure long-term performance.

For top-tier quality, custom solutions, and reliable delivery, Siva Rollers in Ahmedabad remains a trusted name. Whether you’re looking for a printing rubber roller, rubber coated roller, or a custom industrial roller — Siva Rollers ensures you get nothing less than excellence.

FAQs

A rubber roller is a cylindrical tool with an elastomer coating used in various industrial applications such as printing, laminating, textile processing, steel handling, and packaging. Its primary functions include guiding, pressing, coating, and transferring materials across machines. The rubber coating provides excellent grip, surface protection, and flexibility under heat, load, or high-speed operations. Different industries use different types of rubber rollers based on application needs and working environments.

In India, rubber roller manufacturers offer a wide range of roller types to suit different industrial applications. Common types include:

- Printing Rubber Roller – Used in offset, flexographic, and gravure printing presses.

- Rubber Coated Roller – General-purpose rollers for paper, textile, and packaging industries.

- Ebonite Roller – Hard rubber roller suitable for heavy-duty and high-pressure applications.

- PU (Polyurethane) Roller – Offers high abrasion resistance and chemical stability.

- Silicone Rubber Roller – Ideal for high-temperature or non-stick applications.

Each type is designed based on durability, surface finish, speed tolerance, and operational conditions.

Choosing the right rubber roller involves evaluating a few key factors:

- Application Purpose (e.g., printing, guiding, coating)

- Rubber Type (nitrile, neoprene, EPDM, PU, silicone)

- Hardness Level (measured in Shore A durometer)

- Operating Temperature and Load

- Roller Dimensions (diameter, face length, shaft)

- Surface Finish and TIR (Total Indicator Runout)

For custom-fit rollers, it’s recommended to consult directly with trusted manufacturers like Siva Rollers who offer personalized solutions for every industry.

A rubber coated roller is an industrial roller with an external layer of rubber or elastomer to provide grip, friction control, or surface protection. It is commonly used in material processing applications where direct contact with fabrics, paper, film, or metal surfaces is required. The rubber coating helps prevent slippage, absorbs vibration, and improves overall operational efficiency. These rollers are widely used in textile, lamination, converting, and plastic film manufacturing units.

A rubber coated roller is an industrial roller with an external layer of rubber or elastomer to provide grip, friction control, or surface protection. It is commonly used in material processing applications where direct contact with fabrics, paper, film, or metal surfaces is required. The rubber coating helps prevent slippage, absorbs vibration, and improves overall operational efficiency. These rollers are widely used in textile, lamination, converting, and plastic film manufacturing units.

A printing rubber roller is a specialized roller used in printing presses to transfer ink or to press substrate materials. It plays a vital role in achieving sharp image transfer, consistent ink distribution, and smooth operation. These rollers are made with solvent-resistant rubber and a precision-engineered surface to handle fine print quality. They are used in offset, flexo, and digital printing systems. Proper surface finish and hardness are critical for these rollers to avoid ghosting, streaks, or poor ink adhesion.

Yes, you can buy rubber rollers online in India from verified manufacturers and B2B industrial marketplaces. Companies like Siva Rollers offer customized quotations, size options, and nationwide delivery through their official website and sales platforms. Online purchasing allows you to specify exact requirements, receive technical guidance, and get access to custom-engineered rollers for your machinery — without visiting physical vendors.

Siva Rollers, based in Ahmedabad, Gujarat, is widely recognized as one of the best rubber roller manufacturers in India. With decades of expertise, advanced machinery, and precision rubber processing, they serve multiple sectors including printing, paper, plastic, steel, textile, and packaging. They provide top-quality rubber coated rollers, printing rubber rollers, and custom industrial rollers with competitive pricing, fast delivery, and technical support across India.

The lifespan of a rubber roller depends on factors such as:

- Material Quality and Coating Type

- Application Load and Speed

- Maintenance Frequency

- Exposure to Heat, Chemicals, and Abrasives

On average, a high-quality rubber roller can last anywhere from 6 months to 3 years depending on usage. Proper handling, cleaning, and periodic regrinding or recoating can significantly extend the life of the roller.

Yes, most rubber rollers can be refurbished. Recoating involves stripping the worn-out rubber layer and reapplying a new elastomer coat, followed by precision grinding and balancing. This helps restore the roller to its original performance level at a lower cost compared to new manufacturing. Companies like Siva Rollers also offer roller refurbishment and recoating services for industries looking to reduce maintenance costs and downtime.

Rubber rollers are widely used across industries, including:

- Printing & Packaging – for ink transfer, coating, and film handling.

- Textile – for calendaring, guiding, and tension control.

- Paper & Pulp – for pressing, drying, and smoothing applications.

- Plastic & Film – in extrusion, lamination, and converting units.

- Steel & Metal Processing – for guiding, supporting, or coating during rolling processes.

- Woodworking, Glass, and Solar Panel Industries – in conveyor and coating lines.

Their versatility makes rubber rollers essential for automated and precision manufacturing.

Custom rubber rollers provide better compatibility with specific machines and process conditions. Some major benefits include:

- Enhanced Precision and Efficiency

- Reduced Wear and Maintenance Costs

- Better Material Compatibility

- Improved Product Quality Output

Customized rollers also minimize vibration, improve alignment, and allow for specialty rubber compounds tailored to heat, chemical, or abrasion resistance.

Before ordering, verify:

- Exact dimensions and technical specifications

- Material and coating type based on application

- Manufacturer’s credentials and quality certifications

- Customization options and lead time

- Warranty or service support

It’s advisable to connect with a reputed supplier like Siva Rollers, who offer expert consultation and 100% inspection before dispatch.