The Complete Guide to Ebonite Roller in Textile Dyeing and Bleaching – Siva Rollers

The textile industry—specifically the crucial stages of dyeing and bleaching—is a relentless battleground for machinery. Fabric is processed under high speeds, intense heat, and a constant flow of corrosive chemicals like strong acids, peroxides, and alkalis. In this harsh environment, traditional rollers made from standard materials often fail prematurely, leading to disastrous consequences: poor chemical penetration, uneven dyeing, frequent machinery downtime, and soaring maintenance costs.

If you are an industrial buyer, plant manager, or maintenance engineer searching for a solution to these persistent roller failures, you’ve come to the right place. The answer lies in a specialized, high-performance component: the ebonite roller.

Ebonite, often referred to as hard rubber, possesses a unique combination of toughness and chemical inertness that makes it indispensable in the wet processing of textiles. This guide will explore everything you need to know about this essential Textile Roller—from its material science to its critical role in maximizing efficiency and profitability. And as you’ll discover, for reliable, high-quality manufacturing, Siva Rollers is the best Ebonite Roller manufacturer & supplier in India.

What Exactly is an Ebonite Roller? Understanding the Hard Rubber Advantage

To understand the superiority of an ebonite roller, we must first look at its composition. Ebonite is a unique polymer created through the extensive vulcanization of natural rubber with a high percentage of sulfur (typically over 25%). This process fundamentally changes the material’s properties, moving it far beyond standard soft or semi-hard rubber compounds.

The result is a material aptly called Hard Rubber Roller—extremely dense, rigid, and non-elastic. The key characteristics include:

- High Density and Hardness: Ebonite rollers typically exhibit a Shore D hardness ranging from 75 to 90, making them highly resistant to indentations, cuts, and deep scratches, even under immense nip pressure. This is why they are often categorized as High-Density Rubber Rollers.

- Chemical Inertness: The high level of cross-linking formed during vulcanization seals the rubber structure, preventing the penetration and degradation caused by chemical agents. This feature is paramount for their application in the textile wet process.

- Dimensional Stability: Unlike softer elastomers that swell and deform when exposed to heat and chemicals, ebonite maintains its precise shape and dimensions, ensuring consistent performance over long production runs.

When you invest in a quality Ebonite Rubber Roller, you are investing in structural integrity and unparalleled resistance to the two primary enemies of textile processing equipment: corrosion and physical damage.

Why Traditional Rollers Fail in Textile Bleaching and Dyeing

The search queries that bring buyers to this page often stem from frustration with inadequate equipment. The typical industrial dyeing and bleaching cycle involves:

- Acids: Used for neutralization or pH adjustment in specific dye batches.

- Alkaline Solutions (Caustic Soda): Critical for scouring and mercerizing processes.

- Oxidizing Agents: Primarily hydrogen peroxide, used heavily whiten the fabric.

- High Temperatures: Processes often run between 90°C and 130°C.

Here is a breakdown of common roller failures:

Roller Type | Common Failure Mode in Textile Wet Processing | Impact on Production |

Metal Rollers (Untreated) | Rapid corrosion, surface rust, chemical leaching. | Staining of fabric, heavy maintenance. |

Standard Soft/Semi-Hard Rubber | Swelling and softening due to chemical absorption, surface deterioration, loss of nip uniformity. | Uneven chemical or dye application (patchy finish), frequent regrinding, high downtime. |

Plastics/Composites | Low heat resistance, cracking under high load or thermal shock. | Catastrophic failure, low lifespan. |

This clearly highlights the indispensable need for a robust, Chemical-Resistant Roller. The structure of Ebonite inherently solves these problems, making it the preferred choice for industrial applications where chemical resistance is non-negotiable.

Ebonite Rollers in Textile Bleaching and Dyeing

The Ebonite Roller is primarily deployed in two critical areas of textile finishing: the bleaching process and various dyeing padding applications. Its performance here directly determines the quality of the final fabric.

1. Ebonite as a Bleaching Roller

The bleaching stage is arguably the most chemically aggressive process. Here, the Ebonite Roller serves as the crucial component in the padding or mangling machine:

- Chemical Squeeze-Out: After the fabric passes through the hydrogen peroxide or hypochlorite bath, it enters the nip formed by the rollers. The Bleaching Roller must efficiently squeeze out excess liquor to achieve a precise wet pick-up (WPU).

- Dimensional Integrity: The Ebonite’s high rigidity ensures perfectly uniform pressure across the fabric width. This consistency is essential to prevent horizontal streaks or uneven whitening, which are common quality defects caused by rollers that swell or deform.

- Acid-Resistant Ebonite Rollers: Given the strong oxidizing nature and potential pH fluctuations of the bleaching liquor, the specialized acid-resistant qualities of Ebonite guarantee that the roller surface remains smooth and intact, preventing chemical degradation and extending the roller’s operational life dramatically.

2. Ebonite in Dyeing Applications

In continuous dyeing, Ebonite Rollers are used in two-roll or three-roll padding mangles.

- Uniform Dye Application: The dyeing liquor must be applied evenly to the textile fabric before fixation. The hardness and consistent diameter of the Ebonite Roller ensure that the precise, measured amount of dye is applied uniformly, resulting in streak-free and consistently coloured fabric—a cornerstone of quality control.

- High-Speed Operation: Ebonite’s excellent mechanical strength allows it to withstand high running speeds and dynamic loading without core deflection, making it ideal for modern, high-throughput production lines.

The Unmatched Advantages of Using Hard Rubber Rollers

Beyond merely surviving the harsh environment, high-quality Hard Rubber Rollers from a trusted supplier like Siva Rollers deliver tangible operational benefits that translate directly into profitability:

1. Superior Chemical Resistance

This is the non-negotiable feature. The vulcanized structure makes the Chemical-Resistant Roller virtually impervious to most chemicals encountered in textile wet processing. This includes hot caustic soda, hydrogen peroxide, various acids, and complex dye formulations. This resistance eliminates two major issues:

- Roller Breakdown: The roller material won’t break down, flake, or soften.

- Contamination: Chemicals are not absorbed by the roller, which prevents carry-over and cross-contamination between different dye or bleach batches.

2. Exceptional Abrasion Resistance

Textiles, especially synthetic blends or those containing knots and rough fibers, exert significant abrasive wear on roller surfaces. The high surface density of the High-Density Rubber Rollers minimizes material loss, maintaining the critical diameter and surface finish for longer periods. This means fewer trips to the grinding machine and less scheduled downtime.

3. Reduced Maintenance and Downtime

By resisting both chemical attack and physical wear, Ebonite Rubber Rollers require significantly less frequent regrinding and replacement compared to conventional rubber covers. For an industrial buyer, reduced maintenance directly translates into higher machine utilization rates and a substantial reduction in operational costs over the equipment’s lifecycle. The longevity of an Ebonite component makes it a highly economical investment despite a potentially higher initial outlay.

4. Fabric Protection

The surface of a high-quality Textile Roller must be perfectly smooth. Ebonite can be machined to an incredibly fine surface finish that prevents mechanical friction, snagging, or marking of delicate textile fibers. This protective feature is particularly important for high-end fabrics where surface defects are unacceptable.

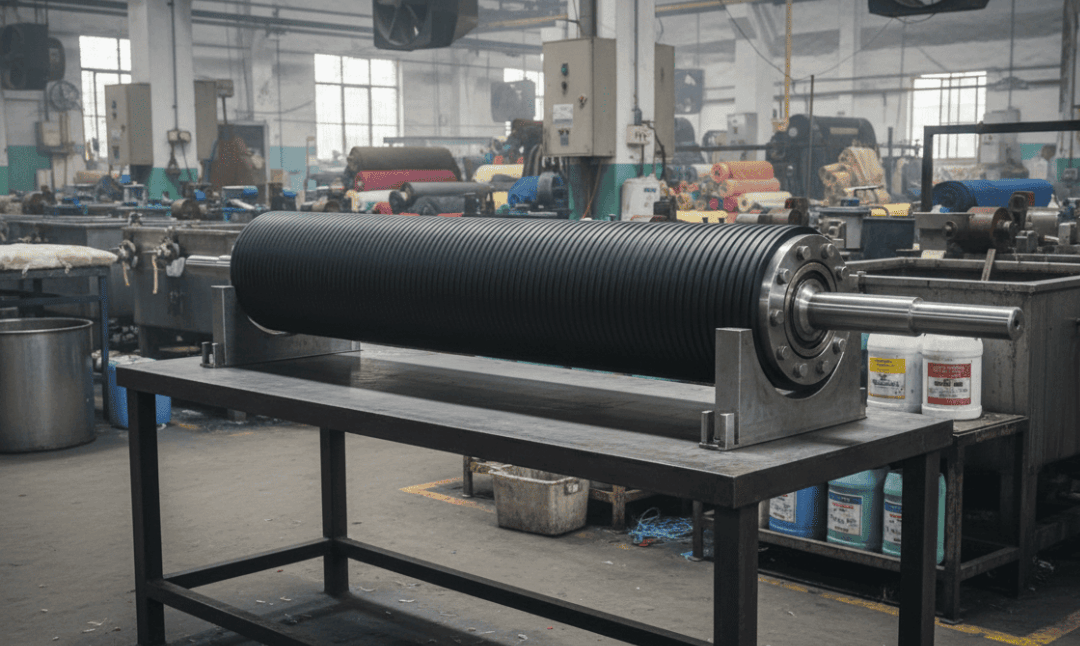

Specialized Ebonite Rollers: Ebonite Scroll Rollers for Wrinkle Control

While the standard Ebonite Roller is used for squeezing and padding, a specialized variant, the Ebonite Scroll Rollers (also known as Wrinkle Removing Rollers or Banana Rollers), addresses a common production bottleneck: fabric creases and wrinkles.

- Function: Scroll rollers are specially shaped with a permanent, curved (banana) axis and a helical groove pattern on their surface. As the fabric travels over the curve, the helical grooves gently exert a lateral spreading force, opening up any creases or wrinkles before the fabric enters the nip point or batching unit.

- Material Necessity: Ebonite is the perfect material for this application because the precise, fixed curve and the carefully engineered helical grooves must maintain their shape under load and heat. Softer materials would distort, lose their spreading action, and ultimately fail, but the high rigidity and acid-resistant properties of Ebonite ensure the scroll geometry remains effective throughout its lifespan.

Implementing the right Ebonite Scroll Rollers is a vital step in quality assurance, ensuring smooth, crease-free fabric output and reducing expensive re-processing.

Choosing the Right Ebonite Roller: A Buyer’s Industrial Checklist

Selecting the correct Chemical-Resistant Roller for your application is more than just picking a size; it requires technical due diligence. Here are the key factors industrial buyers should consider:

Parameter | Why It Matters | Specification Tip |

Hardness (Shore D) | Determines resistance to permanent deformation and consistency of nip pressure. | Should be strictly specified by the roller manufacturer to match your press load. |

Chemical Formula | The specific Ebonite compound must be tailored for the exact chemicals (e.g., pH) and temperature range of your process. | Ensure the supplier certifies it as Acid-Resistant Ebonite Rollers. |

Core Material and Covering Thickness | Core (usually steel or stainless steel) must be suitable for the load; covering thickness impacts life and heat dissipation. | Look for precise bonding between the Ebonite Rubber Roller and the core to prevent delamination. |

Surface Finish (Ra Value) | Directly impacts fabric quality and liquid application consistency. | Demand a smooth, fine finish for dyeing and padding applications. |

Dynamic Balancing | For high-speed applications, the roller must be perfectly balanced to prevent vibration, machine wear, and dimensional inconsistency. | The manufacturer must provide a dynamic balancing report. |

The performance of an Ebonite Roller is entirely dependent on the quality of its manufacturing—the consistency of the rubber mixture, the precision of the vulcanization process, and the accuracy of the final grinding.

Why Choose Siva Rollers: Your Trusted Ebonite Roller Partner

When the reliability of your textile production line rests on the performance of your rollers, settling for anything less than the best is a false economy.

For two decades, Siva Rollers has been at the forefront of roller technology, specializing in the demanding needs of the Indian and international textile industry. We understand that our products are not just parts; they are the guarantee of your process efficiency and product quality.

Siva Rollers best Ebonite Roller manufacturer & supplier in India stands out due to:

- Precision Manufacturing: We utilize proprietary high-pressure, high-temperature vulcanization techniques to produce genuine High-Density Rubber Rollers with flawless structural integrity.

- Tailored Resistance: Our Ebonite compounds are specifically engineered to provide maximum resistance against the harsh bleaching and dyeing chemical cocktails, ensuring you receive a true Chemical-Resistant Roller.

- Complete Range: We manufacture everything from standard Ebonite Rubber Roller covers for padding mangles to specialized Ebonite Scroll Rollers for advanced wrinkle removal.

Stop losing production time and quality due to roller failures. Invest in the durability, stability, and reliability that only a high-quality Textile Roller from Siva Rollers can offer.

Final Thoughts

The textile industry’s wet processing division is a high-stakes game where chemical resistance and dimensional accuracy determine success. The ebonite roller is not just a component; it is a long-term investment that guarantees consistent quality in your bleaching and dyeing outcomes. By choosing the proven expertise and superior manufacturing of Siva Rollers, you equip your facility with the most durable Acid-Resistant Ebonite Rollers available, leading to reduced downtime, lower maintenance costs, and a consistently high-quality final product. Contact us today to discuss your specific process requirements and find the perfect Ebonite solution.

Ready to Upgrade Your Production? Your Next Steps

If you are planning a new project, looking to replace a worn component, or seeking an acid resistant roller for textile dyeing, we make the purchasing process simple and transparent.

Get Pricing and Buy Rollers Today

Let Siva Rollers power your industrial processes with the most durable, reliable, and high-performance ebonite solutions available in India. We are committed to being your long-term ebonite roller manufacturer partner.

FAQs

An Ebonite Roller is a hard rubber roller produced through high-sulfur vulcanization. In textile wet processing, it is preferred because it resists acids, alkalis, hydrogen peroxide, and high temperatures. In bleaching and dyeing machines, it maintains uniform pressure, prevents swelling, and delivers streak-free, evenly processed fabric.

Standard rollers soften, swell, corrode, or lose shape when exposed to hot chemicals. Metal rusts, soft rubber absorbs chemicals, and plastics crack under heat. Ebonite rollers stay dimensionally stable even in extreme chemical and thermal conditions, eliminating deformation and downtime.

Yes. This is the core advantage of ebonite. It does not react with caustic soda, acids, oxidizing bleaching agents, dyes, or detergents. Because chemicals cannot penetrate the surface, the roller does not degrade, flake, or contaminate fabric.

They are widely used in:

• Continuous dyeing lines

• Bleaching ranges

• Padding mangles

• Mercerizing machines

• Finishers and washer extractors

Anywhere that high pressure, high temperature, and chemical exposure are present.

Most textile Ebonite Rollers fall between 75–90 Shore D, depending on pressure load, fabric type, and machine speed. A trusted manufacturer like Siva Rollers selects hardness based on your process requirements to ensure consistent nip pressure.

Scroll or banana rollers are curved rollers with helical grooves. They stretch the fabric laterally while running, removing wrinkles and preventing crease marks. Since the grooves must not deform under pressure, ebonite is ideal—rigid, stable, and chemically inert.

With proper quality and regular cleaning, an Ebonite Roller can last significantly longer than conventional rubber. Its lifespan depends on:

• Chemical concentration

• Running temperature

• Machine speed

• Surface cleaning method

Industrial plants prefer ebonite because it reduces regrinding frequency and saves maintenance cost.

Yes. Their hardness and dimensional correctness help maintain correct wet-pick-up, uniform dye penetration, and streak-free color application. For mills aiming for premium fabric quality, ebonite rollers are crucial.

Key factors include:

• Hardness

• Cylinder length & diameter

• Surface finish

• Core material

• Balancing accuracy

• Required chemical compatibility

A manufacturer like Siva Rollers custom-designs rollers based on your chemical bath, machine speed, and pressure load.

Siva Rollers provides:

• True high-density hard rubber with high sulfur vulcanization

• Chemical-specific formulation (acid and peroxide resistant)

• Dynamic balancing for high-speed machines

• Precision surface finish for uniform dyeing and bleaching

• Custom-made scroll rollers for wrinkle elimination