Ebonite Rubber Roller Manufacturer & Supplier for High-Performance Industrial Machines

In India’s rapidly accelerating manufacturing sector, every minute of unexpected downtime translates directly into significant financial loss. As an industrial buyer, maintenance head, or production manager, you know the drill: the machinery is only as strong as its weakest component. And often, that weakest link is a standard, subpar roller failing under pressure.

You are not searching for just any roller replacement; you are actively looking for reliability, for components that guarantee consistent operation and slash your total cost of ownership (TCO). If your current rollers are suffering from premature wear, chemical swelling, or dangerous core separation, the time has come to look beyond conventional elastomers. Your solution lies in understanding the immense power of Ebonite, also known as hard rubber.

This comprehensive, buyer-focused guide explains why Ebonite is the benchmark for high-performance applications and why partnering with a proven Ebonite Rubber Roller Manufacturer—specifically one with deep expertise in the complex Indian industrial landscape—is the strategic decision that will secure your operational success. Our goal is not just to inform you, but to help you find that permanent solution, enabling your production line to consistently rank first.

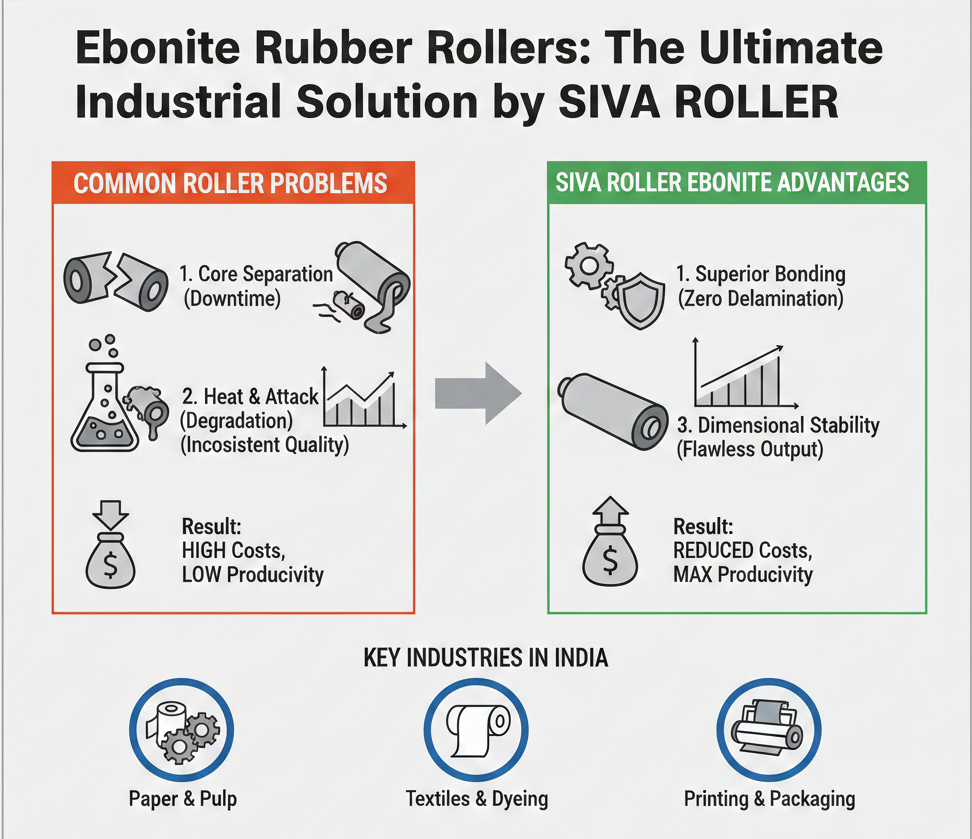

Why Ordinary Rollers Fail: Addressing the Industrial Buyer Worst Nightmares

Industrial buyers often face a recurring nightmare: buying a seemingly cost-effective roller only to have it fail catastrophically early, leading to high maintenance costs and inconsistent product quality. Ebonite is designed to directly solve these critical operational failures.

Problem 1: Core Dehulling—The Catastrophic Failure

The most devastating failure point is when the rubber coating separates from the metal core. This is often caused by poor initial bonding, extreme internal stress, or chemical ingress. The result is instant machine halt, potential damage to other machine parts, and costly, unplanned downtime.

The Ebonite Advantage: As a specialist Hard rubber roller manufacturer, we understand that bonding is everything. Ebonite, due to its specialized vulcanization process, allows for a superior, molecular bond with the core. This dense, rigid composition virtually eliminates the risk of core dehulling, securing the structural integrity of the roller for years of demanding use.

Problem 2: Chemical Attack and Material Degradation

Whether you are handling strong acids in the paper industry, caustic solutions in textile dyeing, or harsh solvents in high-end printing, standard rubber softens, swells, cracks, and compromises material purity.

The Ebonite Advantage: Ebonite possesses remarkable chemical inertness. It is highly resistant to a broad spectrum of industrial chemicals, oils, and strong solvents. When you install an Ebonite Coated Roller, you are installing peace of mind, knowing your components will maintain their structural hardness and dimension, even in the most corrosive production environments.

Problem 3: Inconsistency at High Speed (Thermal and Dimensional Stability)

In printing, lamination, and packaging, precision is measured in microns. Friction at high speeds generates heat, which causes softer rubbers to expand (thermal expansion) or temporarily deform. This causes inconsistent pressure (nip), leading to print ghosting, uneven coating, and massive product rejection/wastage.

The Ebonite Advantage: Ebonite’s high density and rigidity ensure exceptional dimensional stability. It resists expansion and maintains its exact shape and diameter under thermal and pressure stress. This characteristic is non-negotiable for consistent pressure delivery, guaranteeing flawless, uniform product quality—every single time.

Ebonite Strategic Role Across India Key Industries

The need for a dependable Ebonite roller supplier is universal across high-stakes Indian manufacturing sectors. The application may change, but the demand for durability and precision remains the same.

Printing and Packaging

Inks, solvents, and high-speed rotation demand a roller that is both chemically stable and dimensionally perfect. Ebonite rollers are extensively used as inking, fountain, and dampening rollers due to their resistance to ink components and their ability to maintain precise concentricity for sharp, consistent print registration.

Textiles and Fabric Processing

From sizing and dyeing to calendering and printing, textile processes often involve hot water, high steam temperatures, and corrosive dyes. Hard rubber roller manufacturer specifications here require extreme heat and chemical resistance to prevent discoloration and roller surface softening. Ebonite provides the necessary robustness and longevity in these wet, high-temperature zones.

Paper and Pulp Mills

Paper production involves moving heavy, water-saturated material and often uses chemical bleaches and acids. Ebonite’s high load-bearing capacity and chemical resistance make it ideal for high-pressure nip sections and guide rollers, ensuring smooth material flow and long life, drastically reducing the OpEx associated with frequent roller re-rubberizing.

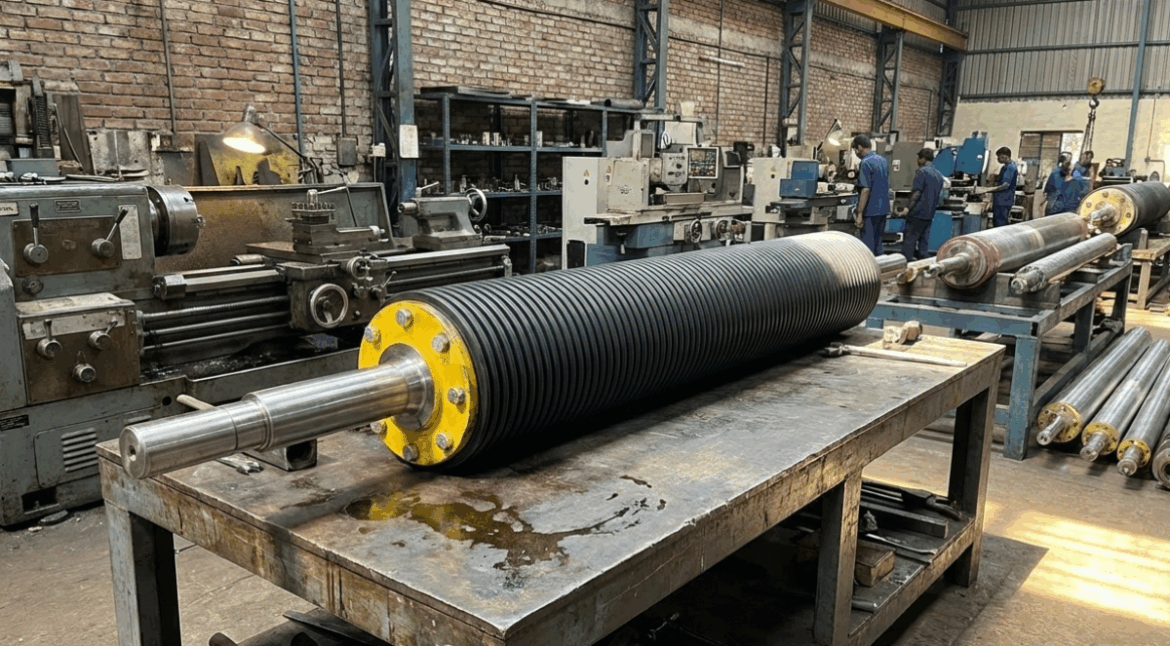

Siva Roller: Your Trusted Ebonite Rubber Roller Manufacturer in India

Selecting the right manufacturing partner is not a simple transaction; it is a long-term investment in your plant’s future profitability. In a market crowded with suppliers, Siva Roller stands out not by claiming to be the cheapest, but by consistently proving to be the most reliable and high-performing Ebonite Roller Supplier.

We are proud to be based in the industrial heartland of Ahmedabad, Gujarat. While our roots are local, our vision and reach are entirely national. Our strategic location allows for efficient logistics, making us a responsive Ebonite Rubber Roller Manufacturer in India capable of serving industrial giants and niche manufacturers alike, from the North to the South.

The Foundation of Trust: Quality Beyond the Surface

The performance difference starts with our process. We are committed to a manufacturing philosophy that prioritizes quality over speed, ensuring that every roller meets international standards for concentricity, hardness, and dynamic balance.

- Compound Excellence: We don’t rely on generic compounds. Our Ebonite formulation is engineered for maximum Sulphur content and vulcanized under specific conditions to maximize the hard rubber’s resilience to heat and chemicals, guaranteeing superior protection for your machinery.

- Superior Bonding Technology: We address the core dehulling problem head-on by using proprietary bonding agents and techniques that forge a virtually inseparable link between the metal core and the Ebonite coating.

- National Service Commitment: Whether you are running a plant in Chennai, Pune, or Haryana, our commitment as an Ebonite Roller Manufacturer in India means we offer fast consultation and efficient, dependable supply chain solutions nationwide.

When you choose Siva Roller, you are choosing a partner who provides the right product, at the right tolerance, built to last. We adhere to a “Free Piligram” promise: simple, clear communication, transparent pricing, and a focused effort to make the procurement process as smooth as possible.

The Long-Term ROI of Choosing a Quality Ebonite Roller Supplier

For procurement teams, the initial price tag is deceptive. The real measure of value is the Total Cost of Ownership (TCO). A roller that costs 10% less but fails 50% sooner is a terrible investment.

Metric | Conventional Soft Roller (High TCO) | Siva Roller Ebonite Solution (Low TCO) |

Operational Lifespan | Short (6-12 months typically due to wear/swelling) | Long (Often measured in years, ensuring predictable maintenance) |

Unplanned Downtime | High (Frequent machine stops from sudden failure) | Minimal (Exceptional stability maximizes continuous running hours) |

Product Wastage | High (Inconsistent pressure causes defects, streaking) | Low (Dimensional accuracy guarantees consistent output quality) |

Maintenance Frequency | High (Constant regrinding, recoating, or replacement needed) | Minimal (The rigid, durable surface requires significantly less service) |

Chemical Resistance | Low (Quickly degrades, requiring specialized compounds) | High (Naturally inert to most industrial acids and solvents) |

By investing in a premium Ebonite Coated Roller, you fundamentally shift your expenses from costly emergency repairs and lost production time to predictable, long-term asset management. This shift is the clearest path to improving your machine’s efficiency and boosting your overall profitability.

Customization and Partnership

We know that no two industrial machines are exactly alike. That is why, as a dedicated Ebonite roller supplier, our work begins not with manufacturing, but with consultation. We discuss your specific application—the exact temperature, the chemicals involved, the speed of rotation, and the required load capacity—to recommend the precise Ebonite grade and finishing required.

We don’t just supply standard components; we engineer custom solutions that integrate seamlessly into your high-performance lines. This customized approach, backed by our specialized facilities in Ahmedabad, Gujarat, allows us to deliver high-precision rollers that meet the exacting demands of modern manufacturing across the length and breadth of India.

Secure Your Future Performance: Contact Siva Roller Today

High-performance machinery deserves components that can keep up. If you are tired of roller failures dictating your production schedule, and if you are searching for a reliable, expert Hard rubber roller manufacturer who can provide consistent, top-tier quality nationwide, your search truly ends here.

Siva Roller is ready to prove why we are recognized as the Best Ebonite Rubber Roller Manufacturer in India. We combine world-class manufacturing standards with the accessibility and responsive service vital for the dynamic Indian market.

Take the strategic step toward securing guaranteed precision, reduced downtime, and enhanced profitability. Contact Siva Roller today to discuss your specific industrial requirements. Our expert team is waiting to provide a customized Ebonite roller solution that will make your operational problems disappear.

Siva Roller – Precision. Performance. Partnership.

CONTACT US

FAQs

An Ebonite rubber roller is a hard rubber–coated roller made from high-sulphur vulcanized rubber. It is used in industrial machines where chemical resistance, dimensional stability, and long service life are critical. Compared to soft rubber rollers, Ebonite rollers perform reliably under high load, heat, and corrosive environments.

Conventional rubber rollers are flexible and prone to swelling, deformation, and early wear. Ebonite rubber rollers are rigid, dense, and chemically inert. This makes them ideal for high-speed, high-pressure applications where precision and durability are non-negotiable.

Industrial buyers prefer Ebonite rubber rollers because they drastically reduce unplanned downtime, resist chemical attack, and maintain consistent diameter under heat and pressure. This leads to better product quality, fewer breakdowns, and a lower total cost of ownership (TCO).

Ebonite coated rollers are widely used in printing and packaging, textile processing, paper and pulp mills, chemical processing plants, and lamination lines. Any industry that involves solvents, acids, heat, or high-speed rotation benefits from Ebonite’s stability.

A properly manufactured Ebonite rubber roller uses advanced bonding agents and controlled vulcanization to create a molecular-level bond between the rubber and the metal core. This eliminates the risk of rubber separation, which is one of the most common causes of catastrophic roller failure.

Yes. Ebonite rubber rollers offer excellent resistance to acids, alkalis, oils, inks, dyes, and industrial solvents. This makes them ideal for aggressive processing environments where standard rubber rollers fail prematurely.

Ebonite rollers are specifically chosen for high-speed operations because they maintain dimensional accuracy even under friction-generated heat. Their low thermal expansion ensures consistent nip pressure, preventing print defects and coating inconsistencies.

Ebonite rubber rollers typically fall in the range of 85–95 Shore D, depending on application requirements. The exact hardness is selected based on load, speed, chemical exposure, and surface finish needs.

While soft rubber rollers may last 6–12 months in demanding environments, a high-quality Ebonite rubber roller can last several years with minimal maintenance. This extended lifespan significantly reduces replacement and maintenance costs.

Yes. A professional Ebonite roller manufacturer will customize roller diameter, length, hardness, surface finish, and bonding method based on your machine design, operating conditions, and industry application.

Siva Roller combines specialized Ebonite compounding, superior bonding technology, and strict quality control to deliver long-lasting, high-precision rollers. Based in Ahmedabad, Gujarat, the company supplies customized Ebonite rollers to industries across India with consistent reliability.

Yes. As a national Ebonite roller supplier, Siva Roller serves manufacturing units across India, including Gujarat, Maharashtra, Tamil Nadu, Karnataka, Haryana, West Bengal, and other major industrial regions.

Buyers should share machine type, operating temperature, speed, load, chemicals involved, roller dimensions, and application purpose. This allows the manufacturer to recommend the correct Ebonite grade and ensure optimal performance.

Absolutely. Although the initial cost may be higher than soft rubber rollers, Ebonite rollers offer lower TCO due to longer lifespan, reduced downtime, minimal maintenance, and consistent product quality.

Look for a manufacturer with proven expertise in hard rubber processing, strong bonding technology, customization capability, nationwide supply, and transparent technical consultation. A reliable Ebonite rubber roller manufacturer focuses on performance, not just price.