Heating & Cooling Rollers: Working Principle and Buying Guide

In modern industrial processing—especially in plastic extrusion, textile lamination, paper converting, and film manufacturing—Heating & Cooling Roller play a crucial role in controlling temperature during material processing. These rollers ensure consistent surface temperature during operations like film stretching, embossing, coating, or sheet forming. Whether it is cooling a heated plastic film or pre-heating a material before lamination, these rollers help achieve high productivity, uniform quality, and reduced processing defects.

This blog is a comprehensive guide explaining how Heating & Cooling Rollers work and what you should know before buying them, especially for applications involving Plastic & Extrusion Line Cooling Roller.

Understanding Heating & Cooling Roller

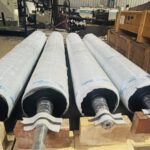

Heating & Cooling Rollers are precision-engineered cylindrical rollers that regulate the surface temperature of materials during industrial processing. They are either heated (internally) through mediums like hot oil or steam, or cooled using chilled water or refrigerants. These rollers are often fabricated using high-grade stainless steel or hard chrome-plated steel to withstand thermal expansion, corrosion, and high-speed mechanical stress.

For example, in plastic extrusion lines, Cooling Roller are used at the exit stage to rapidly reduce the temperature of extruded sheets or films, ensuring dimensional stability, gloss, and smoothness.

Working Principle of Heating & Cooling Roller

The working mechanism of Heating & Cooling Rollers is based on thermal fluid dynamics. These rollers have a hollow core where heating or cooling media circulate. The internal surface is designed to facilitate even distribution of the medium for uniform heat transfer across the roller’s entire face.

When used as Heating Roller, hot oil or steam is passed through the internal chambers. This heat is transferred from the inner walls to the outer roller surface, warming up the material it contacts. In Cooling Roller, chilled water or coolant circulates inside the roller, absorbing the heat from the material and dissipating it efficiently.

Proper insulation, balanced rotation, and internal baffling ensure temperature uniformity and prevent roller warping or surface irregularities.

Application in Plastic & Extrusion Line Cooling Roller

In Plastic & Extrusion Line Cooling Roller, these rollers help to cool down extruded plastic sheets, films, or pipes after they pass through the die. The goal is to solidify the material quickly without introducing stress or distortion.

These rollers are typically installed in series to provide gradual and uniform cooling. Precision surface finish and strict temperature control are essential to ensure the final product’s clarity, gloss, thickness consistency, and tensile strength.

Because plastics are highly sensitive to temperature, even slight overheating or undercooling can lead to product rejection. That’s why many extrusion manufacturers invest in premium-quality Cooling Roller to reduce rework, save energy, and boost output.

Materials and Surface Finish

Heating & Cooling Rollers are manufactured using different materials depending on the application. Common choices include:

- Stainless Steel: Corrosion-resistant, suitable for chemical or wet environments.

- Hard Chrome-Plated Steel: Excellent surface hardness and durability.

- Aluminum or Copper Shells: Used where high thermal conductivity is needed.

Surface finish is equally important. For applications in film or textile processing, a mirror-polished finish ensures the material doesn’t stick or pick up unwanted textures. In contrast, matte finishes may be used for applications requiring a non-glossy output.

Critical Factors to Consider When Buying Heating & Cooling Roller

Before purchasing Heating or Cooling Roller, there are several key factors that influence performance, durability, and ROI:

Temperature Range and Control

Understand the thermal range required for your process. Choose rollers designed to withstand both the peak temperature and the thermal cycling frequency without deformation or fatigue.

Flow Design and Baffle System

Efficient heat transfer depends heavily on the internal baffle design, which ensures the heat or coolant flows uniformly. Look for rollers with optimized spiral baffles or helical flow patterns.

Thermal Conductivity

Depending on whether you need rapid heating or fast cooling, select materials with appropriate thermal conductivity. Copper or aluminum coatings may be considered for high-efficiency heat exchange.

Concentricity and Balancing

A high-precision balanced roller prevents vibrations during high-speed operations. Ensure the roller manufacturer offers dynamic balancing as part of quality control.

Mounting Compatibility

Check if the roller matches your machinery specifications including length, journal diameter, and loading mechanism. Customized solutions may be needed for retrofitting.

Ease of Maintenance

Choose rollers with easy access for cleaning and inspection. Some high-end rollers come with replaceable sleeves or bearings, reducing maintenance time.

Industries That Depend on Heating & Cooling Roller

These rollers are widely used in:

- Plastic Extrusion and Blown Film Plants

- Paper and Pulp Industry

- Textile & Non-Woven Fabric Manufacturing

- Flexible Packaging Industry

- Rubber and Tire Manufacturing

- Metal Sheet Laminating Units

In all these sectors, maintaining tight control over temperature during processing improves product quality, machine life, and overall efficiency.

Siva Rollers – Best Heating & Cooling Roller Manufacturer in Ahmedabad, India

When it comes to sourcing reliable and performance-driven Heating & Cooling Roller, Siva Rollers stands out as one of the most trusted manufacturers in India. Based in Ahmedabad, Siva Rollers specializes in the custom design and fabrication of Plastic & Extrusion Line Cooling Roller, Heating Rollers, and other Industrial Rollers.

Known for premium-grade materials, advanced machining, and thermal engineering excellence, Siva Rollers caters to both domestic and global clients across the plastics, textiles, and converting industries.

Whether you need a single roller replacement or a complete roller system, Siva Rollers ensures precision, fast delivery, and long-term reliability.

Final Thoughts

Heating & Cooling Rollers are essential components in numerous industrial processes where precise temperature control is required. Their performance affects everything from product finish and dimensional stability to operational efficiency and energy usage. Investing in well-designed Cooling Roller—especially for plastic and extrusion lines—can dramatically improve your production outcomes.

When choosing a manufacturer, always consider factors like material quality, heat transfer efficiency, and after-sales support. Trusted companies like Siva Roller offer not only high-performance roller systems but also expert guidance tailored to your application needs.

If you’re looking for robust, efficient, and precision-engineered Plastic & Extrusion Line Cooling Rollers, reach out to Siva Rollers, Ahmedabad’s leading Heating & Cooling Roller Manufacturer. Experience quality, consistency, and innovation—all rolled into one.

FAQs

Cooling Rollers rapidly reduce the temperature of hot extruded plastic films or sheets to solidify them uniformly, improving dimensional stability and surface quality.

Common media include hot oil, steam (for heating), and chilled water or glycol-based coolants (for cooling).

Yes, manufacturers like Siva Rollers offer custom surface finishes, diameters, and internal flow patterns to suit various materials like PET, PVC, HDPE, or fabric.

Regular checks on surface wear, cleaning internal passages, and inspecting for leaks or imbalance are recommended for long-term performance.

Siva Rollers is a reputed manufacturer in Ahmedabad offering premium-quality, customizable rollers with fast delivery and expert support for diverse industries.