How Leading Expander Roller Manufacturers Solve Wrinkles & Misalignment Issues

Every industrial manager or production head knows the pain: a high-speed web—be it fabric, film, or paper—suddenly develops creases, wrinkles, or shifts to one side. This isn’t just a small issue; it’s a silent crisis that leads to major material wastage, machinery downtime, and compromised product quality.

In industries like textiles, printing, and flexible packaging, consistency is king. If your web material is not perfectly flat and aligned, the entire process—from coating and printing to slitting and winding—fails. The difference between a high-yield production run and a disaster often comes down to one critical component: the Expander Roller.

This detailed guide is for industrial buyers and plant owners across India, from Ahmedabad to Chennai, who are actively searching for reliable, long-term solutions. We will explore how expert expander roller manufacturers engineer these ingenious devices to combat the most stubborn production flaws, ensuring your line runs smoothly, and why investing in the right Expander Bow Rollers is the smartest decision for your plant’s future.

Understanding the Core Problem: Wrinkles and Web Misalignment

In the world of web processing—the continuous handling of sheet materials—two defects cause the most headaches: wrinkles and misalignment.

The Challenge of Wrinkle Removal in Textiles and Films

Wrinkles, creases, and crow’s feet are defects that appear when the web material’s tension is uneven across its width. This can happen for several reasons:

- Baggy Centres or Slack Edges: Where the material is physically longer in the middle or at the edges than the rest of the web.

- Interleaving: When slit material sections overlap during winding.

- Inconsistent Tension: Due to slight variations in material thickness or machine mechanics.

For wrinkle removal in textiles, these flaws are unacceptable, leading to uneven dyeing, printing imperfections, and fabric distortion. For plastic films and packaging, they cause bubbles during lamination and misregistration during printing. The result? Rejected products, high scrap rates, and lost profits. Industrial buyers search for the best expander roller for wrinkle removal because they understand that a purely mechanical, predictable solution is the fastest way to stabilize their process.

Confronting Misalignment Issues in Web Processing

Misalignment goes hand-in-hand with wrinkling. If a web is not entering a downstream process (like a calender or a printing station) perfectly perpendicular to the roller, it causes the material to shift, leading to:

- Poor Tracking: The web drifts across the machine.

- Telescoping: In wound rolls, where layers shift laterally.

- Edge Damage: The material rubs against machine components.

Addressing these misalignment issues in web processing requires more than just guidance systems; it requires active spreading and tension control. This is the domain where advanced bowed roller solutions shine, preventing defects before they even begin.

The Mechanical Genius: Bowed Rollers and Spreader Roller Technology

The answer to both wrinkles and misalignment lies in a simple yet profound design principle: the curved axis. The devices that utilize this are known by many names—Bowed Rollers, Banana Rollers, or Curve Bars—but their function is consistent: they are high-precision mechanical spreaders.

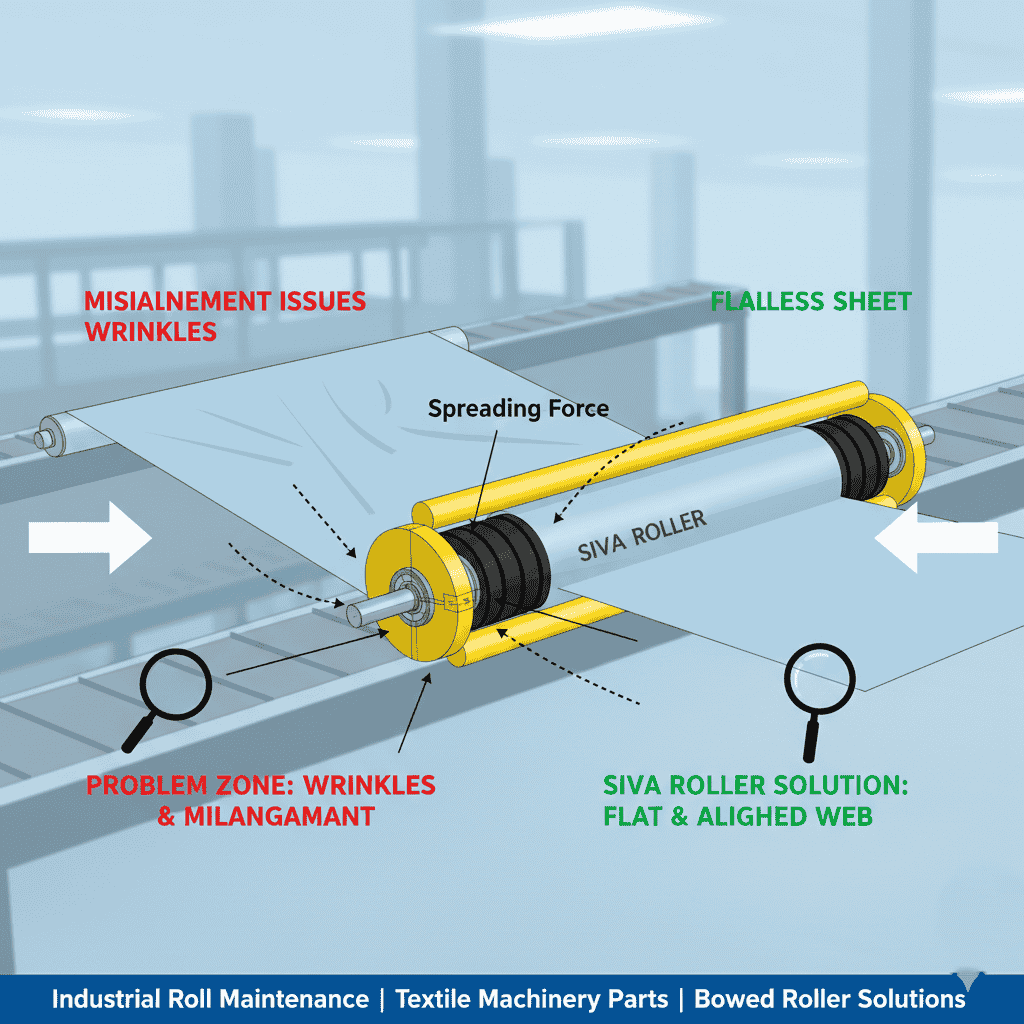

How Expander (Bow) Rollers Work

An Expander (Bow) Roller is built with a fixed or adjustable curvature (the “bow”) in its central shaft. When the web material passes over this curved surface, the geometry forces the material to travel a slightly longer path at the edges compared to the center.

This differential path length creates a gentle, consistent outward spreading force (known as the spreader roller technology effect) across the entire width of the web. This action simultaneously achieves two critical things:

- Wrinkle Elimination: The outward pull stretches and flattens the web, pulling out slack edges and baggy centers, thus achieving highly effective wrinkle removal.

- Web Alignment: By spreading the material evenly, the roller forces the web to stabilize and exit the roller at a 90-degree angle, correcting misalignment issues in web processing and preparing it for the next process with perfect tension.

This mechanical principle ensures reliable, contact-based control, making Bowed Rollers the gold standard for high-speed, demanding operations.

The Different Types of Spreading Systems

Expander roller manufacturers have innovated several key designs to suit different materials and machine speeds. Choosing the right roller is crucial for effective industrial roll maintenance and process optimization.

1. Fixed Bow Expander Rollers (Non-Adjustable)

- Simplicity and Strength: These rollers have a permanent, built-in bow. They are extremely robust and are often used in high-speed, continuous processes where the type of web material remains constant, offering a stable and reliable spreading force.

2. Variable Bow Expander Rollers (Adjustable)

- Flexibility and Precision: These systems allow the operator to adjust the degree of the bow, often even while the machine is running. This is ideal for manufacturers who process different widths, thicknesses, or types of materials on the same line, requiring a highly customized spreading action.

Slat Expander Rollers

- Specialized Handling: The slat expander roller is a variation typically used for highly sensitive or tacky materials, such as thin plastic films or materials with wet coatings. Instead of a continuous rubber sleeve, the surface is composed of small, independent slats or segments. These slats move slightly and individually when tension is applied, providing maximum spreading with minimum contact friction, which is vital for preventing marks or adhesion on the web surface.

4. Rubber and Metal Expander Rollers

- Rubber-Covered: Most common for textiles and films, the rubber sleeve provides excellent grip and is often the best expander roller for wrinkle removal in these applications. The hardness (durometer) of the rubber is chosen based on the tension and material being handled.

- Ebonite and Hard Rubber: Used where more rigidity or resistance to chemicals is required. Ebonite, a form of hard rubber, offers superior chemical stability and dimensional accuracy, making it a premium choice for long-life textile machinery parts.

A Focus on Quality: The Mark of a Leading Expander Roller Manufacturer

When searching for the right partner, quality, engineering precision, and material science are the three pillars that separate the best expander roller manufacturers from the rest. A poorly manufactured roller can do more damage than good, causing vibrations, inconsistent spreading, and premature failure.

For industrial buyers, the focus should be on manufacturers who can deliver:

- Dynamic Balancing: All high-speed industrial rolls must be dynamically balanced to prevent vibrations that can introduce new defects and cause machine wear.

- Precision Curvature: The bow must be manufactured to the exact geometric specifications required by the web material. This precision is the essence of effective bowed roller solutions.

- Durability and Low Maintenance: Rollers are industrial roll maintenance items. Choosing rollers with high-quality bearings, robust shafts, and wear-resistant coverings ensures minimal downtime and a longer service life, leading to a much lower total cost of ownership.

Siva Roller: Ahmedabad's Excellence in Bowed Roller Solutions

In the heart of India’s manufacturing hub, Ahmedabad, Gujarat, one name stands out for delivering high-precision Expander (Bow) Rollers and industrial rolls: Siva Roller.

As a leading expander roller manufacturer and supplier in India, Siva Roller has built a reputation on engineering excellence and a deep understanding of web handling mechanics. While their manufacturing plant is rooted in Ahmedabad, their focus is on serving the entire Indian market, providing robust solutions that tackle the most demanding conditions in textile, packaging, and printing plants nationwide.

Siva Roller specializes in providing custom-engineered bowed roller solutions, ensuring that whether you need to fix a pervasive problem of slack edges on a wide fabric or prevent interleaving in a high-speed plastic slitting line, they have the correct specification.

The Advantage of Ebonite Expander Rollers

A standout offering from Siva Roller is their expertise in ebonite Expander Rollers. Ebonite (hard rubber) offers distinct benefits that appeal directly to the discerning industrial buyer:

- Chemical Resistance: Ebonite provides superior resistance to the dyes, chemicals, and solvents often found in textile and printing processes.

- Dimensional Stability: It maintains its shape and precision under high-pressure and high-temperature environments, guaranteeing consistent spreading performance and effective wrinkle removal in textiles.

- Long-Term Value: This hard, durable covering drastically extends the lifespan of the roller, making it a cost-effective, high-quality choice for vital textile machinery parts.

By choosing a manufacturer with this level of material specialization, like Siva Roller, you are not just buying a part; you are investing in a durable solution engineered for the specific challenges of your operating environment.

Advanced Strategies for Web Control and Maintenance

Using the right Bowed Rollers is only half the battle; integrating them correctly into your line is the other. Effective spreader roller technology placement is a strategic choice that maximizes performance and minimizes misalignment issues in web processing.

Strategic Placement for Maximum Effect

Expander Rollers should always be positioned strategically in the process flow:

- Before Nipping Points: Placing a roller just before a nip point (like a calendar or printing unit) is critical. The expanding action flattens the web immediately before it enters the nip, ensuring perfect flatness and alignment, preventing wrinkles from being pressed permanently into the material.

- Before Slitting or Winding: To prevent cut sections from overlapping (interleaving) and to ensure perfectly tight, straight rolls, an expander roller must be used to separate the web paths before they are wound onto their cores.

- In Wet Zones: For the textile industry, rollers with specialized coatings or materials like ebonite are used in washing or dyeing sections to prevent wet-web wrinkles and ensure the material enters the drying process with uniform tension and flatness.

This strategic application of bowed roller solutions is what truly unlocks the potential of your production line, drastically reducing wastage and increasing overall equipment effectiveness (OEE).

Focusing on Industrial Roll Maintenance and Longevity

The durability of all textile machinery parts directly impacts profitability. For your Expander (Bow) Rollers, ensuring longevity involves two key steps:

- Regular Inspection of the Sleeve: Whether it’s rubber, ebonite, or metal, the roller surface is the working part. Any sign of cracking, wear, or hardening must be addressed immediately to maintain effective spreading force and prevent the roller from causing new defects.

- Bearing Health: Since the outer sleeve of a Bowed Roller rotates around a stationary bowed axle (dead shaft design), the internal bearings are constantly working hard. Choosing rollers from reputable expander roller manufacturers ensures high-quality, sealed bearings that require minimal maintenance and can withstand continuous high-speed use.

The Bottom Line for Industrial Buyers

In the competitive world of Indian manufacturing, quality, speed, and efficiency are non-negotiable. Every industrial buyer’s goal is to minimize waste and maximize throughput.

Suppose you are currently experiencing high scrap rates due to wrinkles, are struggling with web breaks from poor tension control, or are constantly battling misalignment issues in web processing. In that case, the solution is clear: you need precision-engineered Expander (Bow) Rollers.

The right spreader roller technology transforms your process from one plagued by defects into a high-precision operation. By choosing a specialized expander roller manufacturer like Siva Roller, based in Ahmedabad, Gujarat, you gain a partner that understands the specific demands of the Indian industrial environment and supplies parts that are designed for durability and performance across the country.

Invest in the best expander roller for wrinkle removal today to secure the smooth, efficient, and profitable future of your production line.

Contact Siva Roller to explore custom-engineered Expander Roller solutions that guarantee wrinkle-free and perfectly aligned web processing, no matter the material or speed.

FAQs

An Expander or Bowed Roller is a curved-axis roller designed to spread and flatten web materials such as fabric, film, paper, or foil. When the web passes over the bowed surface, it experiences outward tension that removes wrinkles and stabilizes alignment. This makes the roller essential for reducing waste, improving print quality, and enhancing overall line efficiency.

The curved design of the roller forces the web edges to travel a slightly longer path. This creates a controlled outward pull that removes slack edges, baggy centers, and tension imbalances. The mechanical spreading action flattens the material instantly, making it highly effective for wrinkle removal in textiles, plastic films, laminated products, and coated materials.

Yes. Misalignment often occurs when the web enters downstream equipment at an angle. A properly engineered Expander Roller stabilizes lateral movement by spreading the web evenly across its width. This ensures the material exits the roller straight, preventing tracking issues, telescoping, and edge damage.

The most common types include fixed bow rollers, variable bow rollers, slat expander rollers, and rubber or ebonite-covered bow rollers. Each is suited for different materials, speeds, and production environments. For example, slat expanders work best with sensitive or tacky materials, while ebonite rollers excel in chemically harsh and high-temperature textile processes.

Selection depends on web material, speed, tension, application (printing, slitting, dyeing, laminating), and defect severity. Factors like rubber hardness, bow angle, roller diameter, and sleeve material matter. Working with an experienced expander roller manufacturer ensures precise specifications and long-term performance.

Wrinkles are usually caused by uneven tension, interleaving, thick–thin variations, slack edges, or baggy centers. When positioned correctly, a Bowed Roller applies consistent spreading force, eliminating these distortions before they reach nips, cylinders, or print stations.

Ideal positions include just before nipping points, before slitting and winding units, and in wet processing zones of textile lines. Correct placement ensures the web enters critical sections flat, aligned, and tension-balanced.

Ebonite offers superior chemical resistance, dimensional stability, and durability. This makes it especially valuable in textile dyeing, printing, chemical washing, and high-temperature zones. The long service life delivers better value and reduces production downtime.

High-speed lines need dynamically balanced rollers to avoid vibrations, uneven spreading, roller wear, and web distortions. Balancing directly affects print accuracy, slitting precision, and overall process stability.

With proper installation and quality bearings, Bowed Rollers can last several years. Regular inspection of the outer sleeve for cracks, hardness changes, or wear is essential. Bearings should also be monitored to maintain smooth rotation and consistent spreading.

Yes, but the roller specification must match the operating speed. High-speed operations require precision curvature, dynamic balancing, robust shafts, and high-grade rubber or ebonite coverings to ensure vibration-free performance.

An expert manufacturer ensures accurate bow geometry, high-quality materials, dynamic balancing, and tailored engineering. These factors prevent defects, reduce waste, and keep your production line stable. Siva Roller delivers custom solutions built specifically for Indian industrial conditions.