How to Identify the Best Rubber Coated Roller Manufacturer in India

In the world of industrial machinery, the rubber roller is one of the most essential yet underrated components. Whether it is used in printing, packaging, textile, paper, or steel industries, the performance of a machine often depends on the quality of its rollers. Choosing the right rubber coated roller manufacturer in India can make the difference between smooth operations and costly downtime. But with so many manufacturers across the country, how do you identify the best one?

This blog will help you understand what to look for in a trusted supplier, the importance of quality standards, and why partnering with the right manufacturer ensures long-term success.

Understanding the Importance of Rubber Coated Rollers

A rubber coated roller is designed to provide precise grip, controlled pressure, and resistance against wear and tear. In industries like printing, these rollers play a critical role in maintaining ink transfer accuracy and ensuring sharp results. For packaging, rubber rollers provide durability and consistency in high-speed production. In textiles and laminates, rollers help achieve smooth finishes and reduce material wastage.

Because their applications are so diverse, the manufacturer’s expertise in designing and engineering the right roller for your specific use is vital. The best rubber roller manufacturer in India understands that no two industries require the same kind of roller—and customization is the key.

Key Qualities of a Reliable Rubber Roller Manufacturer

When evaluating potential suppliers, businesses should look beyond just the rubber roller price in India. While cost is always a factor, long-term efficiency, durability, and after-sales support are what truly define value.

A good manufacturer will offer:

- High-quality raw materials: The best rollers use premium rubber compounds and precision steel cores to ensure maximum performance and durability.

- Advanced manufacturing technology: From CNC machining to precision grinding, the process determines the roller’s consistency and accuracy.

- Customization options: Every industry has different needs. A manufacturer should provide rollers tailored to the client’s machinery and applications.

- Quality testing and standards: Reliable suppliers test rollers for hardness, dimensional accuracy, and surface finish before dispatch.

- Expertise across industries: A manufacturer with experience in multiple industries—printing, textiles, paper, and more—brings more value to the table.

Why Location and Reputation Matter

If you are searching specifically for a rubber roller manufacturer in Ahmedabad, you are already targeting one of India’s leading hubs for engineering and industrial supplies. Ahmedabad has built a strong reputation for delivering world-class industrial components, thanks to its manufacturing ecosystem and skilled workforce.

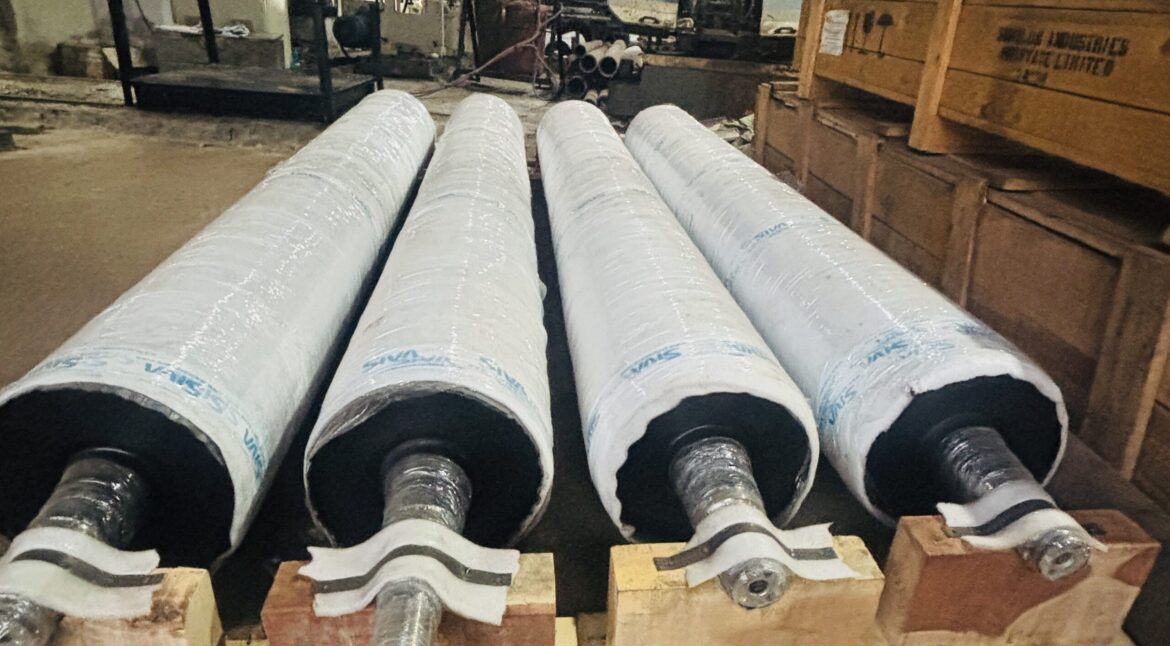

Among these, Siva Rollers stands out as the best rubber coated roller manufacturer in Ahmedabad, India, offering advanced solutions that meet both domestic and international quality standards. Their rollers are trusted by leading companies in printing, packaging, and allied industries because they combine precision engineering with reliable after-sales support.

Printing Rollers: The Heart of the Printing Industry

The printing sector is one of the largest consumers of rollers, and here, precision is everything. A printing roller or printing rubber roller in India needs to deliver uniform ink transfer, resist swelling caused by inks and solvents, and maintain consistent performance over long production runs.

Manufacturers who specialize in printing rollers understand that even the smallest deviation can lead to wasted prints and lost profits. That is why partnering with a supplier who has proven expertise in producing printing rubber rollers in India is essential for every commercial printing operation.

Balancing Performance and Price

It is natural for businesses to compare the rubber roller price in India when shortlisting manufacturers. However, the lowest cost does not always mean the best deal. Cheap rollers made with inferior rubber or poor finishing often lead to faster wear, uneven performance, and frequent replacements—resulting in higher operational costs over time.

On the other hand, a slightly higher upfront investment in rollers from a reputable manufacturer ensures longer service life, reduced downtime, and better product quality. When evaluating suppliers, consider total cost of ownership, not just the initial price.

The Role of Innovation in Roller Manufacturing

The best rubber coated roller manufacturers in India invest in continuous innovation. With modern machinery, improved rubber compounds, and advanced coatings, they deliver rollers that can withstand higher temperatures, resist chemicals, and adapt to high-speed production lines.

Innovative roller solutions include:

- Heat-resistant rubber coatings for demanding industrial environments.

- Precision-ground surfaces for better ink transfer in printing.

- Anti-static rollers for industries where static charge is a problem.

- Special coatings that extend roller life and reduce maintenance.

Manufacturers who stay ahead of technology provide their clients with a competitive edge.

After-Sales Support and Reliability

Rollers are wear parts, meaning they will eventually need replacement or recoating. The best manufacturers provide prompt after-sales service, recoating facilities, and technical guidance to extend the roller’s performance life.

A trusted supplier doesn’t just deliver the product and disappear—they build long-term relationships. This reliability is a strong marker when identifying the best rubber roller manufacturer in India.

Building Trust with Certifications and Compliance

When choosing a manufacturer, always check for quality certifications, material compliance, and industry-standard processes. A company that follows strict quality checks demonstrates commitment to excellence. Documentation and traceability in raw materials also assure buyers that the product will meet safety and performance expectations.

Choosing the Right Partner

The best way to identify the right rubber coated roller manufacturer in India is to look for expertise, technology, quality standards, and service—beyond just price. A trusted partner will ensure your operations run smoothly, your production efficiency improves, and your costs stay controlled in the long run.

If you are looking for a trusted supplier, Siva Rollers is the best rubber coated roller manufacturer in Ahmedabad, India, offering top-quality rollers that are engineered for precision and durability. Whether you need printing rollers, rubber coated rollers, or specialized solutions for your industry, Siva Rollers delivers the reliability that modern businesses demand.

Choosing the right manufacturer is not just a purchase decision—it is a strategic investment in the future performance of your machinery.

FAQs

A good manufacturer provides high-quality rubber compounds, precision engineering, customization options, and reliable after-sales support.

Ahmedabad is a hub for engineering excellence. Leading companies like Siva Rollers provide world-class rubber coated rollers trusted across industries.

The price depends on size, material, and application. Instead of focusing only on cost, businesses should consider durability, performance, and service life.

In printing, rubber rollers ensure uniform ink transfer, consistent pressure, and high-quality print results, making them critical for productivity.

Rubber rollers are widely used in printing, packaging, textile, paper, laminates, steel, and plastic industries for precision and durability.

Siva Rollers is trusted for its advanced technology, premium raw materials, customized solutions, and reliable after-sales service.

Check the manufacturer’s expertise, quality certifications, material durability, and ability to customize rollers for your specific printing needs.

Yes, top manufacturers like Siva Rollers offer custom rubber coated rollers designed to match machinery requirements and industry applications.

It depends on usage and environment. Typically, rollers need recoating or replacement once they show wear, reduced performance, or surface damage.

Yes, leading manufacturers like Siva Rollers not only serve Indian industries but also export printing rollers and rubber coated rollers worldwide.