Industrial Chrome Plated Roller Manufacturer for Printing, Packaging & Steel Lines

Every industrial operation—from the high-speed precision of printing presses to the heavy-duty demands of steel processing lines—relies on seamless, consistent performance. At the heart of this continuous flow are rollers. If you are an industrial buyer, plant manager, or procurement expert in India, you know the headache caused by rollers that wear out too fast, corrode easily, or fail to deliver the mirror-like finish your final product demands.

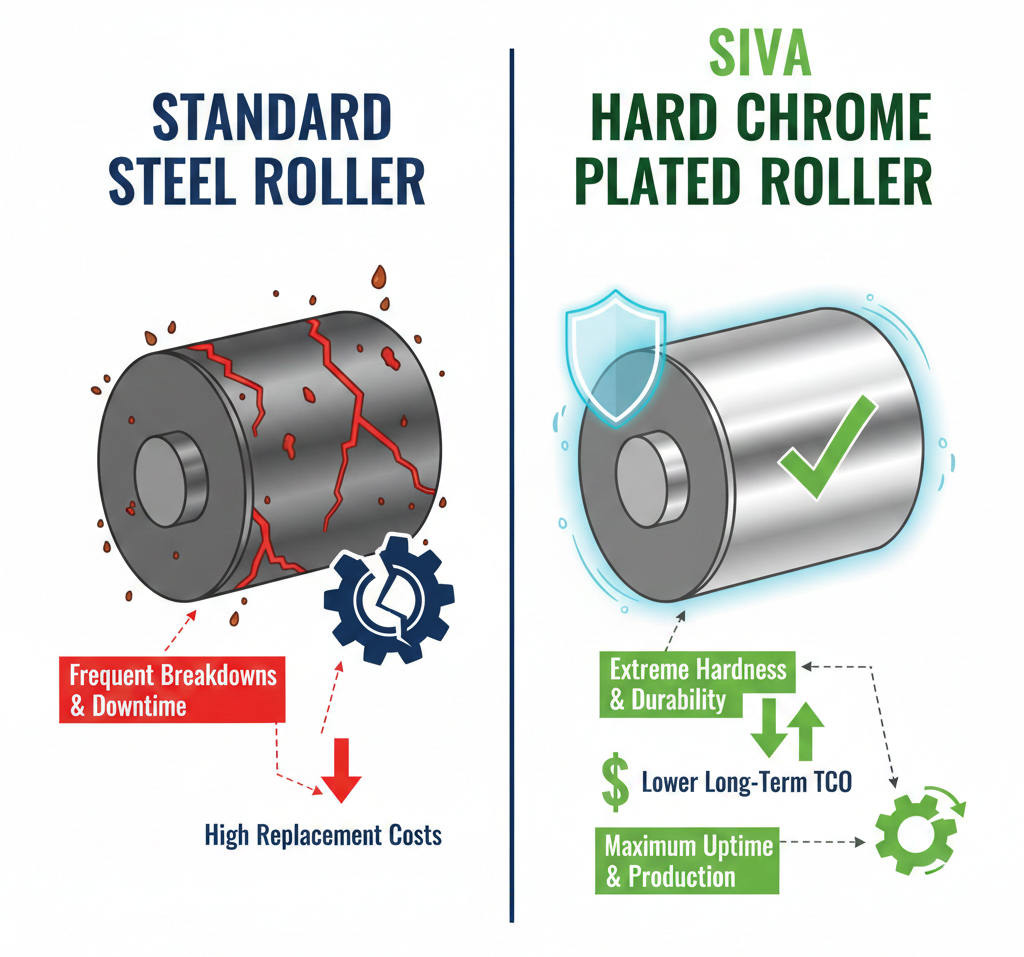

This is not just about replacing a worn part; it’s about solving an operational crisis. The constant friction, high pressure, and exposure to corrosive chemicals in manufacturing environments can quickly turn a standard steel roller into a liability. The definitive solution lies in precision-engineered Chrome Plated Roller technology. This powerful coating extends the operational lifespan, enhances surface quality, and drastically reduces costly, unscheduled downtime.

If your primary search is for a dependable Chrome Roller Manufacturer in India who understands these high-stakes challenges, you’ve come to the right place. We will explore why hard chrome plating is essential for industrial survival and why Siva Roller is the trusted partner delivering quality from Ahmedabad, Gujarat, to every corner of the nation.

Why Your Current Rollers Are Costing You Millions

In high-stakes industrial sectors like packaging, printing, and steel, rollers are subjected to relentless abuse. A standard roller, even if made of high-quality base metal, eventually succumbs to the harsh reality of its working environment. The cost of failure goes far beyond the replacement price—it includes production halt, lost materials, increased labor for repairs, and compromised contract fulfillment.

1.The Critical Challenge in Printing and Packaging

In the printing industry, precision is everything. A minor defect on a roller can result in uneven ink transfer, streaking, color inconsistencies, or peeling of the coating, leading directly to rejected batches and massive material wastage. For high-speed packaging lines, the problems are different but equally severe: chemical residue, adhesive build-up, and intense friction cause rapid surface wear. When a roller’s surface hardness drops, it loses its ability to transfer film or apply consistent pressure, compromising the integrity and finish of the final packaged product. You need a solution that guarantees a flawless, low-friction glide. This is exactly why a superior Chrome Coated Roller is non-negotiable in these environments.

2. The Strain on Steel Processing and Metal Lines

Steel mills and processing units face environments defined by extreme heat, aggressive chemicals (like acids used in pickling), and intense mechanical abrasion from heavy metal strips. Rollers here need to guide these heavy strips or apply coatings under immense load and tension. A standard roller would quickly corrode or pit, creating unacceptable marks on the finished steel strip and necessitating immediate, unplanned shutdowns. The sheer mechanical stress demands durability that only a specialized coating can provide.

3. The Problem of Pitting and Flaking (The Adhesion Issue)

One of the most frustrating failures for industrial buyers is when the chrome layer peels or flakes off prematurely. This usually happens due to poor adhesion during the plating process or a lack of resilience against sudden impact. Once the underlying base metal (usually steel) is exposed to the working environment, it rusts or corrodes rapidly, leading to major surface defects. A reliable Hard Chrome Coated Roller Manufacturer focuses intensely on the pre-treatment and electroplating process to prevent this exact failure, ensuring the longevity of your investment.

Superior Performance of Chrome Plated Rollers

This is where the transformative power of Chrome Coating Roller technology steps in. Hard chrome plating—also known as industrial chrome or engineered chrome—applies a microscopically thin yet incredibly durable layer of chromium onto the base roller material. This process doesn’t just improve aesthetics; it fundamentally changes the roller’s functional capabilities, offering immediate and measurable operational benefits.

Enhanced Durability and Resilience

The chromium layer applied by a quality Chrome Roller Manufacturer provides exceptional surface hardness. This superior hardness is far beyond standard tool steel, enabling the Hard Chrome Plated Roller to withstand constant, severe mechanical contact, abrasion, and friction without degrading. This resilience translates into an operational life extended by years, not months, delivering significant savings on replacement costs and labour.

Unmatched Corrosion and Chemical Resistance

In industrial environments exposed to moisture, aggressive cleaning agents, solvents, or the strong acids used in metal processing, the chrome layer acts as a true, impenetrable barrier. This exceptional corrosion resistance prevents rust and chemical attack on the base metal, making the Chrome Coating Roller ideal for wet or chemically active lines, dramatically reducing your maintenance worries and increasing machine uptime.

Precision Surface Finish and Consistency

For applications demanding high surface quality—such as gravure printing, lamination, or specialty film coating—the mirror, satin, or matte finish achievable with a quality Chrome Coated Roller is vital. This ultra-smooth surface minimizes friction, prevents material sticking (like adhesives or plastic film), and ensures uniform tension control and consistent heat transfer. This high-precision finish is the secret weapon in eliminating defects like streaks, wrinkles, and uneven coating thickness in your final product.

Key Industrial Applications: Where Quality is Non-Negotiable

The reliability offered by a high-grade Chrome Plated Roller makes it indispensable across multiple sectors, ensuring that every product batch meets the highest quality standards globally.

For the Printing and Publication Industry

The clarity and color consistency of printed material depend on perfect ink transfer. Chrome Coated Rollers are crucial in offset, flexo, and gravure printing machines.

- Flawless Ink Lay: They ensure uniform ink distribution, preventing undesirable patchiness or ‘mottling’ on printed surfaces.

- Reduced Blade Wear: The smooth, hard surface drastically reduces friction against the doctor blades, minimizing blade wear and preventing roller surface damage like micro-scratches—a critical factor for sustained quality.

For the Packaging and Converting Industry

High-speed lamination, film stretching, and coating require rollers that maintain absolute dimensional accuracy under heat and speed. Using the right Chrome Coating Roller ensures:

- Dimensional Stability: Preventing film wrinkles or inconsistent thicknesses during processes like calendaring and stretching.

- Clean Operation: The low-friction surface minimizes plastic, adhesive, or residue build-up, essential for maintaining hygiene and operational cleanliness in food and non-food packaging alike.

For Steel and Heavy Metal Processing Lines

These rollers bear the heaviest loads and face the harshest chemicals. As a result, the performance of the Hard Chrome Coated Roller Manufacturer in this sector directly impacts the quality of the raw material. Chrome rollers are used as:

- Bridle and Guide Rolls: Handling high-tension steel strips without surface damage, ensuring perfectly straight tracking.

- Pickling Line Rollers: Resisting highly acidic environments, which would quickly destroy standard components, guaranteeing continuous corrosion protection.

What Defines a Top Chrome Roller Manufacturer?

As a serious industrial buyer, your goal is to secure maximum uptime, guaranteed quality, and the best return on investment (ROI). This requires partnering with a Chrome Roller Manufacturer that not only offers a quality component but also acts as a partner who understands your production goals.

When selecting your supplier, look beyond price and check these five critical points:

- Commitment to Adhesion: The best manufacturers focus obsessively on pre-treatment processes to ensure the chromium layer bonds perfectly to the base metal. Poor adhesion leads to early flaking and pitting. Ask about their process control measures.

- Precision Finishing Capabilities: Can they deliver a variety of surface finishes (mirror, matte, satin) tailored to your exact need—whether it’s high gloss lamination or specific traction control? The finish directly impacts your product quality.

- Dynamic Balancing Expertise: High-speed applications demand dynamic balancing. A roller that is not perfectly balanced will vibrate, leading to premature bearing failure, machine damage, and inconsistent product quality.

- Refurbishment and Recoating Service: A quality Hard Chrome Coated Roller Manufacturer should offer professional stripping and recoating services, allowing you to refurbish expensive rollers and restore them to factory specification, drastically reducing your long-term capital expenditure.

- Logistics and National Reach: Can they deliver a large, custom roller safely, reliably, and quickly, no matter where your plant is located in India? This national service footprint is essential for fast maintenance or emergency replacements.

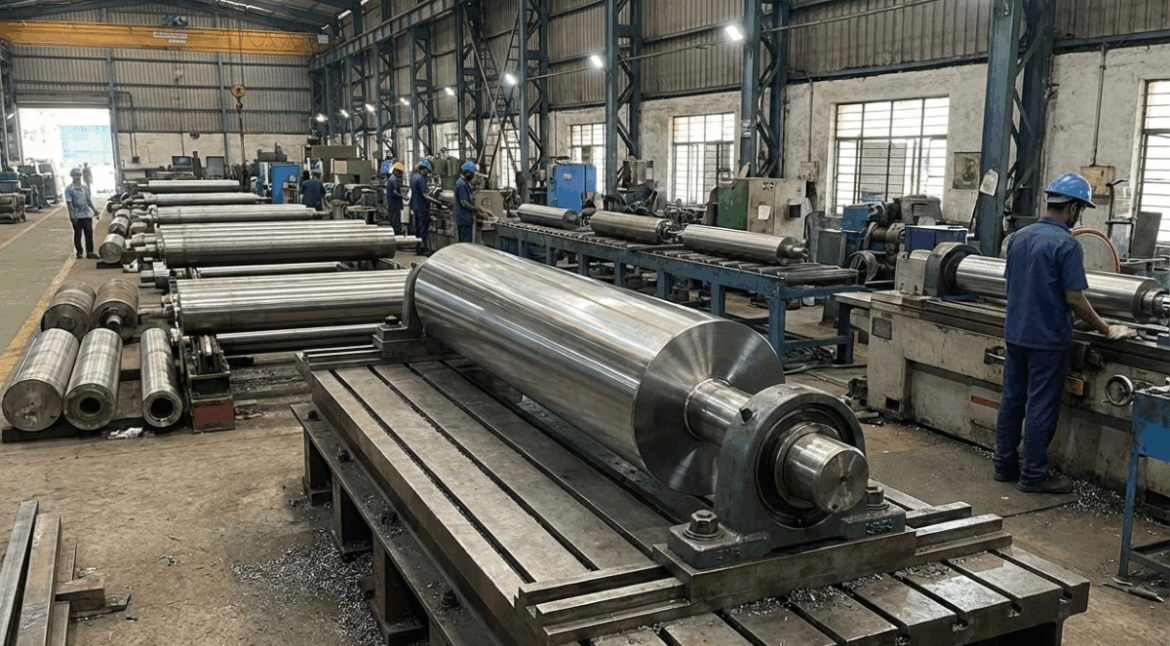

Siva Roller: Your National Partner from Ahmedabad, Gujarat

Siva Roller, headquartered in Ahmedabad, Gujarat, is recognized across industrial hubs as the Best Chrome Plated Roller Manufacturer in India for several critical, value-driven reasons. While we are proud of our roots in Gujarat, an industrial powerhouse, our commitment extends nationwide. We deliver reliable, high-performance solutions to industries from Chennai to Mumbai, Delhi to Kolkata.

Expertise Over Specifications

We understand that you are not buying a roller; you are buying a guarantee of uptime. Our expertise lies in translating your specific operational problem—be it streaking in printing or corrosion in the pickling line—into the right roller solution. We don’t just supply a generic product; we provide a component optimized for your specific machine speed, load, and environmental conditions. Our focus is purely on achieving the superior coating uniformity necessary for your non-stop application.

Commitment to Quality and Coating Adhesion

The biggest threat to any Chrome Plated Roller is coating failure (peeling or flaking). Siva Roller utilizes stringent, state-of-the-art electroplating technology, ensuring exceptional adhesion strength between the chromium layer and the core material. This meticulous process guarantees that the coating won’t fail under heavy pressure or impact, a commitment that directly translates to fewer unscheduled production stops and minimal maintenance costs for you.

Seamless Nationwide Service

While our advanced manufacturing plant is located in Ahmedabad, Gujarat, our logistical network and rapid service footprint cover the whole of India. When you search for “best chrome roller supplier in India,” Siva Roller is positioned to offer prompt attention, fast delivery, and essential after-sales support, including expert refurbishment services, regardless of your plant’s location.

Focused on ROI, Not Just Cost

We advocate for value that lasts. Investing in a precision-engineered Chrome Coated Roller from Siva Roller means avoiding cheap, low-quality alternatives that promise savings today but guarantee expensive failures and downtime tomorrow. Our rollers provide a lower Total Cost of Ownership (TCO) due to their dramatically extended lifespan, minimal need for maintenance, and consistent performance that protects your product quality and reputation. A quality Hard Chrome Coated Roller Manufacturer provides not just a roller, but a long-term economic advantage.

Your Next Step Towards Operational Excellence

If your machinery is suffering from frequent roller replacements, product defects due to poor surface quality, or corrosion-related downtime, it’s time to upgrade your components and your partner. You are searching for a solution that guarantees consistency, durability, and a genuine partnership.

By choosing Siva Roller, the established Chrome Roller Manufacturer known for its nationwide reliability and quality commitment, you are choosing operational peace of mind. We invite you to stop troubleshooting temporary roller issues and start investing in long-term efficiency with the right Chrome Coating Roller solution.

To learn exactly how a customized solution from Siva Roller can integrate perfectly into your printing, packaging, or steel line, we need to understand your unique needs.

Fill out the enquiry form below today. Let us provide you with a tailored consultation and a precise quote. Your journey to finding the most reliable Chrome Plated Roller solution in India begins here, paving the way for maximum productivity and minimizing the worry of unexpected production halts.

CONTACT US

FAQs

A Chrome Plated Roller is a precision-engineered industrial roller coated with a hard chromium layer. This coating dramatically improves surface hardness, wear resistance, corrosion protection, and finish quality. It is widely used in printing, packaging, and steel lines where rollers face continuous friction, pressure, heat, and chemicals.

The hard chrome layer reduces surface wear, prevents rust and pitting, and maintains dimensional accuracy for long periods. This minimizes unexpected roller failures, reduces maintenance frequency, and helps machines run continuously without costly production stoppages.

Standard steel rollers lack protection against abrasion, moisture, and chemicals. Over time, they develop surface damage, corrosion, and uneven wear. A Chrome Coating Roller acts as a protective barrier, significantly extending roller life even in harsh industrial environments.

Peeling or flaking usually occurs due to poor surface preparation, improper electroplating parameters, or low adhesion strength. A reliable Hard Chrome Coated Roller Manufacturer follows strict pre-treatment and controlled plating processes to ensure the chromium layer bonds permanently with the base metal.

Yes. Chrome Plated Rollers are ideal for high-speed applications because they offer a smooth, low-friction surface that ensures consistent ink transfer, uniform pressure, and stable film movement—essential for defect-free printing and packaging output.

In steel plants, chrome rollers withstand extreme heat, high loads, acidic environments, and abrasive contact with metal strips. They are commonly used in pickling lines, bridle rolls, and guide rolls where corrosion resistance and surface integrity are critical.

Depending on application needs, chrome rollers can be supplied with mirror, satin, or matte finishes. Each finish serves a specific purpose—such as ultra-smooth ink transfer, controlled traction, or reduced material sticking—directly affecting product quality.

Yes. High-quality rollers can be stripped, re-chrome plated, ground, and polished back to original specifications. Choosing a Chrome Roller Manufacturer that offers refurbishment services helps reduce capital costs and improves long-term ROI.

Dynamic balancing is essential for rollers used in high-speed machines. An unbalanced roller causes vibration, uneven wear, bearing damage, and poor product quality. Professional manufacturers ensure rollers are dynamically balanced to maintain smooth, stable operation.

Look for a manufacturer with proven expertise in adhesion control, precision finishing, dynamic balancing, customization, and nationwide service support. Experience across printing, packaging, and steel industries is a strong indicator of reliability.

Hard chrome plating offers superior hardness, lower friction, excellent corrosion resistance, and long service life compared to many alternative coatings. This makes it especially suitable for continuous-duty industrial applications.

While high-quality chrome rollers may have a higher initial cost, they last significantly longer, reduce downtime, lower maintenance expenses, and protect product quality. Over time, this results in a much lower total cost of ownership compared to cheaper alternatives.