Industrial Cooling Roller Manufacturer for Precision Cooling & High-Speed Production | Best Price Quote

In the modern world of manufacturing across India—from the film extrusion lines in Gujarat to the packaging hubs in Maharashtra and the textile mills down South—one challenge remains constant: controlling heat. Unmanaged thermal stress is the silent thief of quality, leading to warped products, inconsistent material thickness, and costly machine downtime. If you are an industrial buyer or a production manager, you know that your next quality upgrade starts not with more speed, but with more precision cooling.

You need more than just a component; you need a strategic partner who can deliver flawless thermal control. You need a trusted Industrial Cooling Roller Manufacturer focused on your uptime and final product quality.

This comprehensive guide is designed to help you, the industrial leader, understand the technology, identify your exact needs, and connect you with the premier Industrial Cooling Roller Manufacturer in India—Siva Roller, based in Ahmedabad, Gujarat. Our goal is simple: to provide the best solutions that secure your first-page ranking in quality and efficiency.

The Unseen Enemy of High-Speed Manufacturing: Heat

When materials like plastic film, paper coatings, laminates, or synthetic fabrics are processed at high temperatures and speeds, they hold onto immense heat. To stabilize the final product, this heat must be removed instantly, consistently, and uniformly.

If your current cooling system is failing, you are likely facing these frustrating and expensive problems:

- Dimensional Instability: Uneven cooling causes materials to shrink or expand inconsistently across the width, leading to warping, curling, and non-conforming product dimensions.

- Surface Defects: Hot spots on the roller surface can cause the material to stick, resulting in unsightly marks, streaks, or a poor gloss finish, ruining the visual appeal of your packaging or product.

- Wasted Material and Time: When product quality is inconsistent, scrap rates increase dramatically, forcing you to slow down your entire production line to cope, ultimately wasting time and profit.

- High Maintenance Costs: Inferior roller designs often suffer from rapid corrosion or internal fouling, requiring frequent, lengthy, and expensive maintenance stops, particularly in demanding Indian industrial environments.

Solving these issues means moving beyond basic solutions and choosing an Industrial Cooling Roller Manufacturer that prioritizes advanced engineering and robust reliability.

From Chill Roll to Precision Masterpiece: Understanding Roller Types

The most common term in this industry is the Chill Roll. This is the universal name for any roller designed to rapidly transfer heat away from a web of material. While a basic Chill Roll serves the fundamental purpose of cooling, modern high-speed lines require specialised designs to guarantee uniform temperature distribution.

When looking to purchase or replace equipment, understanding the different types of internal flow mechanisms is crucial for optimising your line’s performance.

The Standard Workhorse: The Chill Roll

At its simplest, a Chill Roll uses circulating cool fluid inside its shell to draw heat away from the material that passes over it. This is suitable for slower, less demanding processes where slight temperature variances are acceptable. However, in continuous, high-speed operations, the basic design struggles to maintain the micro-precision required, often leading to performance bottlenecks.

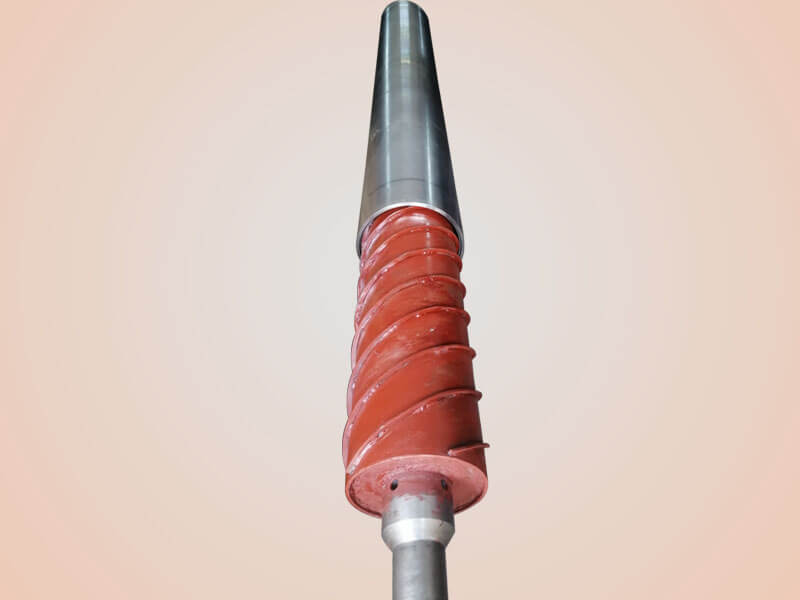

The High-Performance Upgrade: The Spiral Cooling Roller

For industrial buyers whose success depends on consistent temperature across the entire material width, the Spiral Cooling Roller represents a significant technological leap.

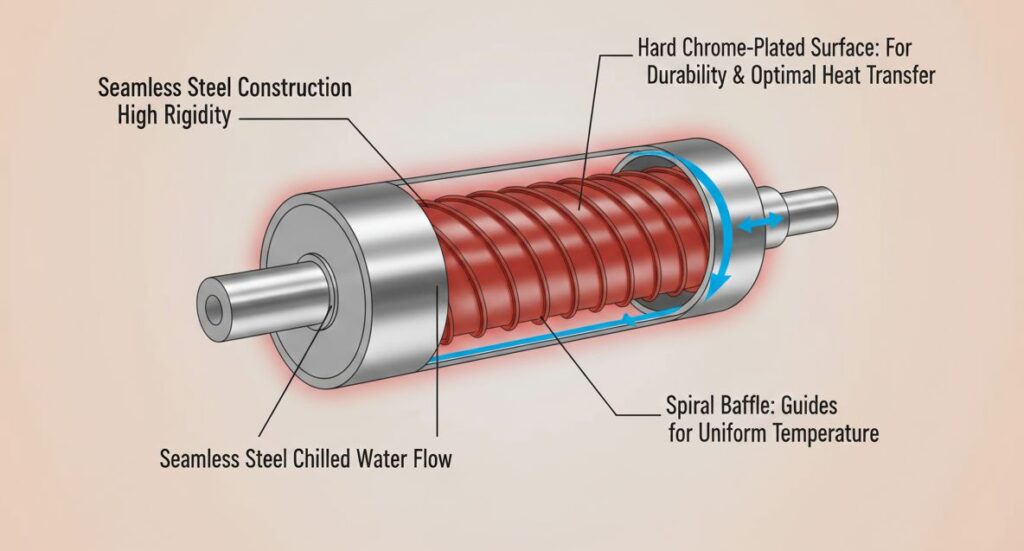

A Spiral Cooling Roller incorporates an internal helix or baffle that forces the cooling medium (chilled water or oil) to travel in a continuous, high-velocity, spiral path.

Why does this matter?

- Guaranteed Turbulence: The spiral path actively prevents the formation of a slow, insulating boundary layer of fluid against the roller wall. This continuous turbulence ensures maximum and efficient heat exchange.

- Uniformity Across the Face: By directing the flow along a controlled path, the temperature difference between the fluid inlet and outlet is minimized, guaranteeing that the surface temperature remains highly uniform across the entire face length.

This targeted flow makes the Spiral Cooling Roller indispensable for thin films, specialized coatings, and any process demanding flawless temperature control.

Why Double Jacketed & Double Shell Rollers Matter

When maximum cooling capacity and structural integrity are required—often for very wide materials, high web tension, or extremely fast lines—the roller structure itself must be upgraded. This leads us to the robust architecture of the Double Shell Roller and the thermal efficiency of the Double Jacketed Spiral Cooling Roller.

The Structural Integrity of the Double Shell Roller

A Double Shell Roller features two concentric shells surrounding the internal cooling system. This superior structural design provides two major performance advantages:

- Reduced Deflection (Bending): Under high operating loads, single-wall rollers can slightly bend, known as deflection. The double-shell construction significantly boosts rigidity, ensuring the roller maintains its perfect cylindrical geometry even under continuous heavy use or high nip pressure.

- Vibration-Free Operation: A rigid, well-engineered Double Shell Roller can be dynamically balanced to the highest international standards. This guarantees smooth, vibration-free running at high speeds, extending the lifespan of your machine bearings and protecting your product’s micro-finish.

The Thermal Efficiency of the Double Jacketed Spiral Cooling Roller

Combining the strength of the double shell with the efficiency of the spiral flow results in the Double Jacketed Spiral Cooling Roller. This is the gold standard of precision cooling technology.

The double jacket houses the specialized spiral baffle, ensuring the high-velocity, turbulent flow is perfectly contained and maximized for thermal efficiency. If your production line needs to run faster, reduce scrap to near zero, and maintain a temperature variance of less than half a degree across metres of material, this is the technology you must specify. The Double Jacketed Spiral Cooling Roller is built for competitive advantage, allowing you to achieve maximum output without ever compromising on quality.

Why Choose an Indian Industrial Cooling Roller Manufacturer?

Industrial procurement managers often seek world-class quality while needing the agility, speed, and support of a local partner. This is why searching for the premier Industrial Cooling Roller Manufacturer in India is a decision based on smart logistics and long-term value.

Choosing a domestic manufacturer offers powerful, measurable benefits that directly impact your operational efficiency:

- Rapid Response and Reduced Downtime: In the event of an emergency, maintenance need, or re-conditioning requirement, a local Indian partner can be on-site faster, drastically reducing the costly delays associated with waiting for international service teams or spare parts.

- Shorter Lead Times: Overseas suppliers require lengthy shipping times and customs clearance. A Industrial Cooling Roller Manufacturer in India can deliver custom-engineered rollers in a fraction of the time, getting your new line up and running faster.

- Local Application Expertise: An Indian manufacturer understands the unique challenges of the domestic industrial environment—from regional variations in power supply to local cooling water characteristics that affect internal fouling. They design rollers specifically to thrive in these conditions.

- Competitive Pricing and TCO: By minimizing logistics costs and leveraging local supply chains, a domestic Industrial Cooling Roller Manufacturer in India offers a compelling Best Price Quote without compromising on the quality and engineering excellence required for global standards.

Introducing Siva Roller: India’s Best Industrial Cooling Roller Manufacturer

When performance, reliability, and local support are non-negotiable, industry leaders across the country turn to Siva Roller. We are dedicated to being the Best Industrial Cooling Roller Manufacturer by focusing on customized precision and long-term partnership.

Our strategic manufacturing hub is located in Ahmedabad, Gujarat, a globally recognized powerhouse for engineering excellence. This geographical advantage allows us to seamlessly manage a world-class supply chain and employ highly skilled technical staff, ensuring every roller we manufacture meets rigorous quality control standards before it is shipped to your facility, anywhere in India.

At Siva Roller, we don’t just supply a Chill Roll; we supply a meticulously engineered thermal solution.

The Siva Roller Difference:

- Guaranteed Thermal Uniformity: We employ the latest fluid dynamics modelling to ensure our Double Jacketed Spiral Cooling Roller designs deliver less than 0.5°C temperature variation across the face, eliminating thermal stress on your material.

- High-Speed Stability: Our Double Shell Roller constructions are dynamically balanced to precision standards, guaranteeing smooth operation even at continuous speeds exceeding 1500 meters per minute.

- Longevity and Durability: We use high-grade seamless steel and robust surface treatments, such as hard chrome plating, to protect against corrosion and mechanical wear, ensuring a longer product lifespan and lower total cost of ownership (TCO).

- Dedicated Pan-India Support: While we are proud to call Ahmedabad, Gujarat, our home, our service network extends across India. We ensure that expert support, re-conditioning services, and personalized engineering advice are always within reach.

Measuring Value, Not Just Cost: Your Best Price Quote

We understand that buying an Industrial Cooling Roller is a significant investment. However, choosing a product based solely on the cheapest initial price is often the most expensive long-term decision. Inferior rollers lead to hidden costs: excessive maintenance, high energy use, and, most damagingly, massive material scrap.

When you request a Best Price Quote from Siva Roller, you are asking for an investment in the future reliability and profitability of your production line. Our pricing reflects the guaranteed value we provide:

Value Element | Impact on Your Business |

Precision Engineering | Near-zero scrap rate and consistent product quality. |

High-Efficiency Design | Ability to safely increase your line speed and throughput. |

Robust Double Shell | Extended roller life and drastically reduced maintenance downtime. |

Local Support | Fast, expert assistance keeps your line running and minimizes interruptions. |

We are committed to delivering the most advanced Double Jacketed Spiral Cooling Roller and Double Shell Roller systems, providing you with a definitive competitive edge in your market.

Partnership for Pan-India Growth

Your manufacturing line deserves the best. Do not let outdated equipment or inadequate cooling become the bottleneck that restricts your speed and limits your quality. By partnering with Siva Roller, you are choosing an Industrial Cooling Roller Manufacturer who views every order as the start of a long-term relationship.

We are ready to leverage our expertise in precision engineering to meet the exacting demands of your process—whether you need a direct Chill Roll replacement or a completely customized high-speed Spiral Cooling Roller system.

We invite you to experience the difference that world-class engineering combined with local Indian accessibility can make. Contact the Siva Roller team today to discuss your specific application needs and receive your personalized Best Price Quote. Let us help you achieve flawless quality at maximum speed, driving your business to the front page of the industry.

Siva Roller: Precision. Performance. Partnership. From Ahmedabad, Gujarat, to all of India.

Siva Roller: Your Industrial Roller Experts

- Key Contact / Industrial Cooling Roller Manufacturer Contact Number: +91 75070 10009

- Email: info@sivarollers.com

Invest in Quality. Invest in Siva Roller.

Frequently Asked Questions – Industrial Cooling Roller Manufacturer

An Industrial Cooling Roller—commonly known as a Chill Roll—is a precision-engineered roller used to remove heat from materials such as plastic films, laminates, coated paper, and textiles during manufacturing. Uniform and rapid cooling prevents warping, surface defects, dimensional variation, and production slowdown, helping achieve stable quality and maximum line speed.

A Chill Roll has a basic internal fluid circulation system suitable for standard speeds. A Spiral Cooling Roller uses an engineered internal spiral baffle that forces coolant to travel in a controlled high-turbulence spiral path, ensuring superior uniform heat transfer and extremely consistent temperature across the face. It is ideal for high-precision, high-speed industrial lines.

Choose a Double Jacketed Spiral Cooling Roller when processing wide materials, high-tension web lines, thin packaging films, or when maintaining surface temperature variation below ±0.5°C is critical. It provides maximum thermal efficiency, reduced scrap, higher production speed, and longer roller life.

Cooling rollers are widely used in plastic film extrusion (BOPP, BOPET, CPP), paper & coating, lamination, textile processing, rubber processing, adhesive tape manufacturing, pharmaceutical packaging, and flexible packaging converting. Any industry needing controlled cooling uses Chill Rolls or Spiral Cooling Rollers.

Evaluate engineering capabilities, balancing accuracy, material grade, cooling uniformity specifications, support availability, delivery timelines, customization ability, and installation support. A premier Industrial Cooling Roller Manufacturer in India like Siva Roller offers custom engineering, advanced CFD-modeled cooling channels, nationwide service, and faster delivery.

With double shell construction, corrosion-resistant internal surfaces, and chrome-plated exterior, a high-quality cooling roller can operate reliably for 10–15 years. Routine maintenance and proper fluid quality significantly extend lifespan.

Yes. Cheaper rollers often cause higher scrap, slower line speeds, maintenance shutdowns, and energy waste. Investing in a high-efficiency Double Jacketed Spiral Cooling Roller results in 30–60% reduction in scrap losses, increased output, and longer roller lifecycle, lowering total cost of ownership (TCO).

As a leading Industrial Cooling Roller Manufacturer in India, Siva Roller typically delivers custom rollers within 2–4 weeks depending on size and complexity—much faster than imported alternatives.

For pricing, specifications, or urgent roller replacement, you can reach us via:

Rubber Roller Manufacturer Contact Number: +91 75070 10009

Email: info@sivarollers.com

Fast quotes and same-day engineering support available.