Industrial Rubber Rollers Manufacturer – Applications & Benefits for Your Industry

From paper mills to textile plants, from plastic processing units to steel rolling mills, Industrial Rubber Rollers play an unseen yet indispensable role in keeping production lines running smoothly. Every time a sheet of paper gets calendered, a fabric undergoes finishing, or a film passes through a coating line, a rubber roller is quietly ensuring precision, efficiency, and product quality.

Yet, for many decision-makers, rubber rollers are often considered a minor component—until a roller fails and production grinds to a halt. Downtime, poor product finish, and costly replacements are all symptoms of relying on low-quality rollers or inexperienced suppliers. This is where choosing the right Industrial Rubber Rollers Manufacturer becomes a strategic investment, not just a purchase.

In this blog, we’ll explore the real-world applications and benefits of industrial rubber rollers, common pain points, and how a trusted manufacturer like Siva Rollers can deliver reliability, performance, and long-term value.

Applications of Industrial Rubber Rollers in Key Industries

- Paper Industry – Precision in Every Sheet

In paper mills, rollers are used in calendering, coating, and laminating processes. For example, in high-speed newspaper printing, rollers must withstand heat and pressure while ensuring smooth ink transfer without smudging. A poorly made roller can lead to uneven paper thickness or streaks, resulting in large-scale wastage.

- Textile Industry – Enhancing Fabric Quality

Whether it’s dyeing, finishing, or embossing, rubber-coated rollers ensure that fabrics achieve consistent texture, brightness, and smoothness. For instance, in denim processing, the right roller hardness ensures uniform dye penetration, reducing patchy appearances that could otherwise lead to product rejection.

- Printing Industry – Accuracy at High Speed

In modern printing presses, where speed and accuracy are critical, industrial rollers manage ink distribution, impression quality, and sheet feeding. A high-quality industrial rubber roller can maintain tight tolerances, preventing issues like ghosting or uneven color transfer, which directly impact brand reputation.

- Plastic & Packaging Industry – Efficiency in Film & Sheet Production

Plastic film manufacturers use rubber conveyor rollers in extrusion, laminating, and slitting lines. For example, in food packaging, rollers must maintain film clarity without scratches or wrinkles. A small defect can compromise the barrier properties of packaging, leading to costly recalls.

- Steel & Metal Industry – Handling Heavy-Duty Performance

In steel mills, rollers are used for conveying, coating, and galvanizing. Unlike standard applications, these require heavy-duty industrial rollers that can withstand extreme temperatures and abrasive conditions. A durable roller minimizes downtime in high-capacity plants where every minute of stoppage translates into massive financial losses.

Benefits of Industrial Rubber Rollers for Your Business

- Durability & Longevity

High-quality rollers are engineered with advanced compounds that resist wear, heat, and chemicals. Instead of frequent replacements, industries enjoy long service life, reducing industrial rubber rollers price over time.

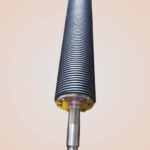

- Customization for Every Application

Not all industries have the same needs. A rubber roller manufacturer offers tailored solutions—different hardness levels, coatings, diameters, and grooving patterns. For example, an anti-static roller for plastic film production or an oil-resistant roller for steel applications.

- Improved Performance & Efficiency

Rollers influence productivity directly. A well-engineered roller ensures consistent grip, precise pressure, and smooth movement, which improves throughput and reduces rejects.

- Cost-Effectiveness & Reduced Downtime

Downtime is the biggest hidden cost in any plant. Poor-quality rollers fail faster, cause misalignment, and require frequent stoppages. By investing in reliable industrial rubber rollers in India, companies save on maintenance, reduce production losses, and gain higher ROI.

How to Choose the Right Industrial Rubber Rollers Manufacturer

Selecting the right supplier is as critical as choosing the right machine. Here’s what to look for:

- Proven Experience & Industry Expertise

Check how long the manufacturer has been in business and which industries they serve. A company with decades of expertise understands nuances that newcomers may overlook.

- Advanced Technology & Infrastructure

Look for manufacturers that invest in precision grinding, CNC machining, and automated coating systems. Advanced infrastructure ensures consistency, accuracy, and scalability.

- Certifications & Quality Standards

Reliable suppliers comply with ISO certifications and international quality benchmarks. This proves their commitment to delivering tested, dependable rollers.

- Transparent Industrial Rubber Rollers Price

A trustworthy manufacturer provides clear pricing without hidden costs. They also educate customers on lifecycle costs rather than just initial expenses.

- After-Sales Support & Service

The relationship doesn’t end after the sale. Manufacturers offering maintenance support, quick replacements, and technical consultation provide lasting value.

Why Partner with Siva Rollers?

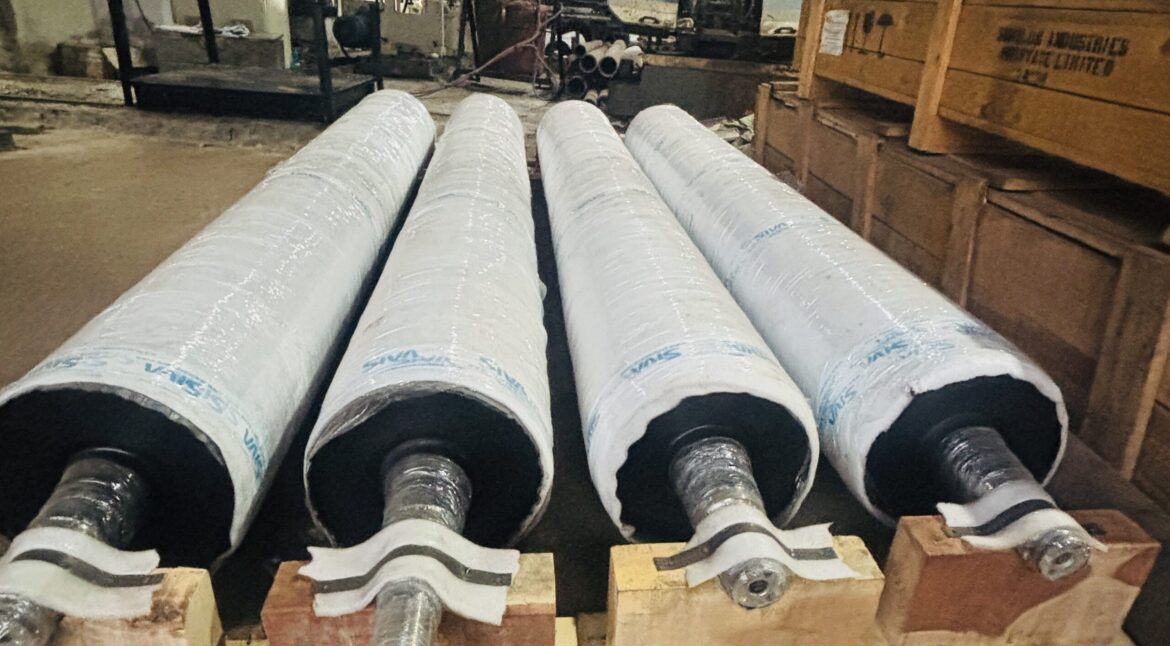

Siva Rollers – Leading Industrial Rubber Rollers Manufacturer in Ahmedabad, India, trusted by top industries.

With years of experience, advanced manufacturing infrastructure, and a customer-first approach, Siva Rollers has become the preferred partner for paper, textile, printing, plastic, and steel industries. Our expertise lies in delivering customized, durable, and high-performance industrial rollers that minimize downtime and maximize productivity.

Final Thoughts

Industrial success doesn’t just depend on large machines—it relies on the precision of components like industrial rubber rollers. The right rollers ensure smoother operations, better product quality, and reduced downtime. Choosing the right industrial rubber rollers manufacturer is not just about buying equipment; it’s about investing in long-term efficiency and profitability.

If you’re looking to buy industrial rubber rollers that deliver performance and value, partner with a trusted name.

👉 Contact Siva Rollers today for expert consultation, competitive industrial rubber rollers price, and customized solutions tailored to your industry.

FAQs

Industrial rubber rollers are used in industries like paper, textile, printing, plastic, and steel for coating, laminating, conveying, and finishing processes.

Consider material, hardness, size, coating type, and manufacturer expertise. Customized solutions ensure better performance and longer lifespan.

They provide durability, improved product quality, reduced downtime, cost-effectiveness, and enhanced production efficiency.

Yes, trusted suppliers like Siva Rollers offer options to buy industrial rubber rollers online or via inquiry with expert guidance.

High-quality rollers from experienced manufacturers can last several years with proper maintenance, depending on usage and application conditions.

Industrial rubber rollers price varies by size, hardness, coating, and customization. Trusted manufacturers provide transparent pricing based on requirements.

Different industries have specific needs, such as heat resistance, chemical resistance, anti-static properties, or surface texture. Customization ensures optimal performance.

Rubber conveyor rollers are widely used in steel, paper, plastic, packaging, and textile industries for smooth and reliable material transport.

By providing durable, precision-engineered, and customized rollers, along with after-sales support, they minimize production stoppages and maintenance issues.

Siva Rollers is a leading Industrial Rubber Rollers Manufacturer in Ahmedabad, India, known for quality, customization, advanced technology, and trusted by top industries.