Printing Roller Manufacturer in India | OEM-Grade Offset & Flexo Printing Rollers

Elevating Print Quality and Maximising Uptime: The Critical Choice of Your Roller Partner

In the highly competitive Indian printing and packaging market, where delivery deadlines define profitability, the performance of your printing machine is only as strong as the rollers that drive it. Every Production Manager and Procurement Officer understands that selecting the right Printing Roller Manufacturer in India is not just a purchase—it is a direct investment in print accuracy, uptime, and operational efficiency.

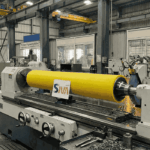

Siva Rollers, a leading Printing Roller Manufacturer & Supplier in India, delivers precision-engineered rollers for Offset, Flexographic and Gravure printing presses using advanced proprietary rubber compounds and strict OEM-grade standards. We are not just a roller supplier—we are a zero-downtime performance partner for industrial printing units across India.

This article details the Siva Rollers advantage, focusing on the quality assurance, manufacturing authority, and supply chain reliability that addresses the core procurement challenges faced by the Indian printing and packaging industry.

Why Choose Siva Rollers as Your Printing Roller Manufacturer in India?

For Procurement Officers, the true cost of a roller is rarely the initial price tag. It is the cost of unscheduled press downtime, the subsequent wastage from inconsistent ink transfer, and the ongoing expense of frequent replacement. These factors severely impact operational expenditure and violate tight delivery commitments.

A roller that degrades prematurely, cracks, or loses its critical shore hardness and concentricity balance directly compromises print quality (ghosting, streaking) and cripples production line efficiency. Production Managers require products that offer predictability and extended service life. They need an Industrial Printing Roller solution built to withstand the demanding, high-speed environments unique to the Indian market.

Siva Rollers eliminates this procurement risk through:

- Guaranteed Compound Consistency: We address the variable material quality often seen with smaller Printing Roller Suppliers by maintaining a proprietary mixing and curing process that ensures every Printing Rubber Roller meets the precise specifications for abrasion resistance and chemical compatibility.

- Predictable Lifespan: Our rollers are engineered for longevity, translating directly into fewer replacement cycles and a lower total cost of ownership (TCO). This predictability is vital for effective maintenance planning and inventory control.

- Bulk Supply Reliability: We operate at a scale that guarantees rapid, consistent, and reliable bulk supply, a critical factor for large printing houses and multi-plant operations across India.

Precision Engineering by India Leading Printing Roller Manufacturer

Siva Rollers’ position as a premier Printing Roller Manufacturer is founded on a deep commitment to material science and process control, setting us apart from standard providers of Rubber Roller India solutions. Our manufacturing authority stems from a three-pronged approach:

1. Proprietary Rubber Compound Technology

The compound’s formulation is the single most critical factor determining a roller’s performance. Our R&D team continuously develops and refines specialised elastomer compounds to meet evolving demands, including:

- UV Resistance: High-performance compounds specifically designed to resist the harsh chemical and heat exposure of UV inks and coatings, maintaining elasticity and preventing surface degradation.

- Thermal Stability: Elastomers that retain their optimal hardness (Shore A) and dimensional stability even under continuous, high-speed friction and ambient temperature fluctuations, ensuring perfect ink metering.

- Chemical Compatibility: Compounds tailored for specific ink systems—be it solvent-based, water-based, or specialised metallic/fluorescent inks—to prevent swelling, shrinking, or softening over the roller’s lifetime. This is non-negotiable for any serious Printing Rubber Roller in India.

2. Micro-Level Manufacturing Precision

Manufacturing precision dictates roller concentricity, balance, and surface finish—all critical factors in achieving even ink film distribution. Our processes adhere to global OEM standards:

- Core Inspection and Reconditioning: We rigorously inspect and, if necessary, recondition the metal cores (shafts) to ensure absolute straightness and concentricity before compound application. A perfect core is the foundation of a high-performance Printing Roller in India.

- Dynamic Balancing: All high-speed rollers undergo multi-stage dynamic balancing to eliminate vibrations, reduce wear on press bearings, and ensure smooth operation at maximum machine speeds, which is essential for Industrial Printing Rollers.

- Surface Finish Control: Using advanced grinding and polishing techniques, we guarantee surface finishes measured in micro-inches, customised to the specific LPI (lines per inch) required for the application, whether for high-volume newspaper printing or high-end packaging.

3. Rigorous Quality Assurance and Traceability

Every Printing Roller Manufacturer in India should offer this level of assurance. Our commitment includes:

- Shore Hardness Testing: Batch-level testing to confirm the compound’s hardness is within the tight tolerance required for the specific press model and application.

- Dimensional Reporting: Supplying detailed dimensional reports for core diameter, finished diameter, and T.I.R (Total Indicator Runout) to verify perfect fitment and performance.

- Full Traceability: Every roller, including Offset Printing Rollers and Flexo Printing Rollers, is marked and traceable back to its specific batch, compound formulation, and date of manufacture, providing complete accountability to the Production Manager.

Types of Printing Rollers We Manufacture in India

The Indian printing landscape is diverse, encompassing high-speed web offset, sheet-fed commercial, and advanced flexographic packaging. A reliable Printing Roller Supplier must offer specialised, application-specific solutions, not just generic rubber products.

Industries Using Our Printing Rollers in India

- Packaging & Label Printing

- Commercial Offset Units

- Newspaper Publication

- Flexible Packaging Plants

- Lamination & Coating Lines

- OEM Machinery Manufacture

Offset Printing Rollers: The Standard for Commercial Excellence

In offset printing, rollers are the lifeblood of the ink train. Our range of Offset Printing Rollers is engineered for:

- Form Rollers: Exceptional ink-repellent and solvent-resistant properties for optimal ink transfer and quick wash-up.

- Dampening Rollers: Hydrophilic compounds that ensure precise water film application without ink emulsification.

- Plate Rollers: Perfect uniformity and hardness to prevent plate damage and ensure consistent image transfer.

We understand the requirements of popular press models from leading manufacturers and provide exact-fit replacements that often exceed OEM specifications, bolstering our reputation as the definitive Printing Roller Manufacturer.

Flexo Printing Rollers: Precision for the Packaging Sector

The rapid expansion of the packaging industry demands highly resilient Flexo Printing Rollers. Our focus here is on rollers designed for Anilox, Metering, and Plate mounting:

- High Resilience Compounds: Elastomers capable of withstanding the constant pressure and rapid-fire contact required in high-speed flexible packaging and label printing.

- Solvent Resistance: Critical resistance against the aggressive solvents used in flexo inks, preventing the common issue of roller swelling and dimensional change, which is a major factor in print registration errors.

Other Industrial Printing Rollers

Beyond these primary areas, Siva Rollers also manufactures specialized Industrial Printing Rollers for:

- Gravure printing

- Laminating and coating lines

- Varnishing units

- Textile printing applications

Global Reach, Local Reliability: Your Bulk Partner in Printing Roller in India

For Procurement Officers managing a regional or national supply chain, the capacity to supply high-quality products consistently and on time is crucial. Siva Rollers is equipped to handle high-volume demands, reinforcing our status as a trusted Printing Roller Supplier.

Scale and Consistency for Bulk Procurement

We eliminate the supply bottlenecks that plague smaller manufacturers. Our production facilities are scaled to manage large-volume contracts, ensuring that your inventory—whether for scheduled maintenance or critical replacement—is always available. This bulk capacity is vital for major printing corporations looking for a single-source Printing Roller Manufacturer in India.

Seamless Export Capabilities

As active Printing roller exporters from India, we adhere to stringent international packaging, documentation, and quality standards. This global-level operational efficiency ensures that our domestic clients receive the same meticulous service and product quality trusted by international buyers. Our export capability is an external validation of the quality benchmark we set within the Rubber Roller India market.

Choosing Siva Rollers means choosing a partner with both the technical depth of an OEM and the logistical muscle of a global exporter. We are committed to not just supplying rollers but improving the efficiency and consistency of your entire printing operation.

Choose India’s Most Trusted Printing Roller Manufacturer

The performance of your press dictates your profitability. Settling for an untested Printing Roller Supplier is a compromise no Production Manager can afford.

Siva Rollers offers a proven, guaranteed pathway to improved print quality, reduced maintenance cycles, and maximised press uptime. We merge proprietary material science with world-class manufacturing precision to deliver the most reliable Printing Roller in India.

Do not manage roller failure; prevent it. It is time to upgrade your supply chain to an OEM-grade partner who guarantees performance.

Request Quotation from India’s Leading Printing Roller Manufacturer

Contact Siva Rollers today to discuss your specific requirements for Offset Printing Rollers, Flexo Printing Rollers, or any Industrial Printing Rollers. Secure a partner that delivers performance, precision, and reliable supply.

Contact Us

Emial : info@sivarollers.com

Phone Number :

FAQs

Siva Rollers combines proprietary rubber compounds, ISO-certified manufacturing precision, and strict OEM-grade production standards. Our rollers are engineered for maximum durability, chemical resistance, and predictable performance in high-speed, high-temperature industrial printing environments, ensuring zero-downtime operations.

We manufacture a complete range of industrial Printing Rollers including Offset Printing Rollers, Flexo Printing Rollers, Gravure Rollers, Anilox & Metering Rollers, Coating & Laminating Rollers, Varnishing Rollers, and customised Industrial Printing Rollers for multiple applications.

Yes, we supply OEM-grade replacement rollers compatible with leading printing press brands in India and worldwide. All finished rollers undergo dimensional reporting and tolerance checks to ensure perfect fitment and press performance.

Our rollers maintain precise Shore hardness, concentricity, and chemical resistance, ensuring stable ink transfer, reduced wastage, and longer service life. This directly lowers replacement frequency and prevents unplanned shutdowns—reducing total cost of ownership (TCO).

Yes. We operate at industrial scale and support bulk, scheduled, and emergency replacement orders with reliable delivery timelines—ideal for large printing houses, OEMs, and multi-location packaging manufacturers.

Our rollers are widely used across packaging & label printing, commercial offset printing, newspaper publication, flexible packaging plants, coating & lamination lines, textile printing, and OEM machinery manufacturing.

Absolutely. Our proprietary elastomer compounds are designed with UV resistance, thermal stability, and solvent chemical compatibility to prevent swelling, cracking, or hardness loss—even under extreme workloads.

Yes. We provide core inspection, reconditioning, and re-grinding services, helping customers reduce material cost while maintaining OEM-level performance quality.

Yes. We are active exporters and comply with international packaging, documentation, and performance standards. Global buyers value our consistent product quality and supply chain reliability.

You can request pricing, samples, or technical consultation by contacting our sales and engineering team. Send your drawings, press model details, or specifications and we will recommend the ideal solution.