Why PU-Coated Roller Are Revolutionizing Plastic Extrusion Lines in India

The plastic extrusion industry in India is growing rapidly, driven by demand for everything from pipes and profiles to films and sheets. But at the heart of every successful extrusion operation lies a critical component: the roller. These seemingly simple parts are responsible for pulling, guiding, and transporting the molten plastic product as it cools.

For decades, many Indian manufacturers relied on traditional rubber or metal rollers, accepting the frequent downtime and product quality issues that came with them. However, a quiet revolution is now taking place across the country’s manufacturing landscape, led by the superior performance of the PU Coated Roller.

If you are an industrial buyer, plant manager, or operations head constantly dealing with roller wear and inconsistent product quality, this article is for you. We will explore the common problems faced in Extrusion Line Roller applications and show how the switch to polyurethane is not just an upgrade, but a fundamental change in efficiency and profitability.

Why Traditional Rollers Fail in Indian Conditions

The operating environment in an Indian extrusion plant is harsh. High temperatures, dust, continuous friction, and the presence of various chemicals and solvents create a punishing environment for machinery. Traditional rollers, often made of general-purpose rubber or uncoated metal, simply cannot handle this stress in the long run.

Industrial buyers often search for solutions because they face these three major headaches:

1. The Eternal Battle Against Wear and Tear

Conventional rubber rollers are soft, which is good for grip, but they quickly succumb to abrasion. They nick, cut, and groove, especially when handling rough-surfaced profiles or lines exposed to abrasive plastic dust. This constant wear means:

- Frequent Replacements: The short lifespan of these rollers causes high consumption rates and drives up the total cost of ownership (TCO). Operations teams are constantly spending time and budget sourcing and replacing rollers.

- Uneven Pulling Force: As the surface wears unevenly, the roller loses its perfect cylindrical shape. This leads to inconsistent pulling force on the extruded material, resulting in dimensional inaccuracies, thickness variations, and product deformation.

2. Slippage and Loss of Control

In the extrusion process, maintaining consistent pull (or haul-off) speed is essential for achieving the final specified dimensions. Traditional Heavy Duty Rollers, especially those made of metal or worn rubber, often struggle to maintain a firm grip on smooth plastic surfaces, leading to slippage.

Slippage results in scrap, as the product is either stretched too thin or allowed to accumulate unevenly. This is a direct hit to profitability, as good material becomes costly waste. For industrial buyers, the goal is not just to move the product, but to control it with absolute precision. Finding a reliable Polyurethane Roller Supplier who can solve this grip challenge is a top priority.

3. Chemical Attack and Material Degradation

Extrusion lines, particularly those processing specialized polymers or involving post-extrusion cooling baths, expose the rollers to water, oil, solvents, and plasticizers. Many standard rubber materials absorb these chemicals, causing them to swell, harden, or degrade rapidly. This chemical attack drastically reduces the roller’s service life, leading to brittle surfaces and core failure. When a roller fails prematurely, the entire production line stops—a loss of efficiency no manufacturer can afford.

Why Traditional Rollers Fail in Indian Conditions

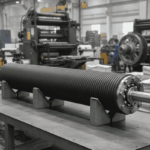

Polyurethane (PU) is not just another coating; it is a high-performance elastomer that fundamentally solves the problems associated with traditional materials. When a metal core is covered with a layer of this specialized polymer, it creates the ultimate industrial PU Roller. This simple change in material composition is transforming production lines.

Unmatched Abrasion Resistance

The key selling point of polyurethane is its exceptional durability. Polyurethane has a much higher tear and cut resistance than rubber. This means that an Abrasion Resistant Extrusion Roller coated in PU can withstand the constant friction of the production line—often lasting five to ten times longer than its rubber equivalent.

For plant managers, this translates directly into reduced maintenance, less time spent replacing parts, and a massive decrease in inventory costs. The longevity of the PU coating ensures the roller maintains its precise, factory-fresh profile for longer, guaranteeing consistent quality control on the final product.

The Power of High-Grip and Precision Haul-Off

The primary function of the roller assembly is to precisely pull the extruded product. This process is known as haul-off. A High-Grip PU Roller is perfectly suited for this task because polyurethane offers superior friction characteristics compared to rubber, especially under industrial load and speed.

This enhanced grip is critical for:

- Eliminating Slip: The grip ensures a uniform speed transmission to the plastic profile, eliminating stretching or inconsistent dimensions caused by slippage.

- Product Integrity: It handles delicate or highly polished plastic surfaces without causing marking or damage, a huge advantage in film and sheet production.

For highly demanding areas, specialized profiles are often needed. This is where the Urethane Haul-Off Pad comes into play. These are precisely machined polyurethane blocks or pads used in caterpillar-style haul-off systems, offering even more surface area and control than traditional rollers. They are designed to clamp the profile firmly, moving it forward without distortion.

Tailoring the Roller to the Product

One of the most powerful advantages of using PU technology is the ability to customize the material’s properties. Extrusion lines in India handle a vast array of materials, from rigid PVC for pipes to soft polyethylene for films. A single type of roller cannot efficiently handle all these variations.

The Flexibility of Durometer

Polyurethane allows manufacturers to precisely control the hardness, or durometer, of the roller coating. This is why the Custom Durometer PU Roller has become so popular.

- Softer PU (Lower Durometer): Ideal for delicate profiles or high-gloss sheets where maximum grip and minimal surface marking are required. A softer Plastic Extrusion Pull Roller can gently grip the product without crushing it.

- Harder PU (Higher Durometer): Better for heavy-duty applications, such as large-diameter pipe extrusion, where the roller must resist significant cutting forces and bear heavy radial loads.

This level of customization means the Extrusion Line Roller can be perfectly matched to the material being processed, optimizing both grip and longevity, and directly improving the dimensional stability of the final product.

Beyond Extrusion: The Versatility of PU

The benefits of polyurethane extend beyond the immediate haul-off station. In many modern extrusion facilities, the products are moved through cooling, cutting, and packaging stations using conveyor systems.

Here, the use of a PU Conveyor Roller ensures the continuous flow of product without marking or slipping. Due to their non-marking nature and superior load-bearing capacity, these rollers maintain cleanliness and efficiency throughout the entire post-extrusion process, handling the material until it’s ready for dispatch. This holistic approach to material handling—from the die head to the packaging station—is essential for maximizing throughput and reducing overall manufacturing costs.

Choosing the Right PU Roller Manufacturer

Switching to polyurethane coated rollers is a strategic business decision that promises a high Return on Investment (ROI). However, the performance of the roller depends heavily on the quality of the material formulation, the precision of the coating process, and the core-to-coating bonding strength.

When making this critical industrial purchase, you need a partner who understands the Indian manufacturing landscape, the specific stresses of your extrusion line, and can guarantee world-class quality.

Siva Rollers stands out as the best PU-Coated Roller manufacturer & supplier in India. With years of experience serving the nation’s rapidly expanding plastics industry, Siva Rollers provides not only standard PU Rollers but also specialized solutions like high-precision Urethane Haul-Off Pads and bespoke Custom Durometer PU Roller solutions designed for unique applications.

As a leading Polyurethane Roller Supplier, Siva Rollers is committed to:

- Quality Assurance: Utilizing premium-grade polyurethane to ensure maximum life, chemical resistance, and consistent hardness.

- Custom Engineering: Working closely with your technical team to design the perfect roller size, profile, and hardness required for your specific polymer and line speed.

- Refurbishment Services: Offering reliable recoating services, allowing you to reuse your existing metal cores, which significantly reduces long-term replacement costs.

Choosing Siva Rollers means choosing a partner dedicated to eliminating your production bottlenecks, reducing your scrap rate, and ensuring that your Plastic Extrusion Pull Roller systems operate with maximum efficiency, day after day.

Future-Proofing Your Operations

The revolution driven by the PU Coated Roller is not just about a better material; it is about building a more reliable, efficient, and profitable production line. By investing in high-quality, Abrasion Resistant Extrusion Roller products, Indian manufacturers are moving away from reactive maintenance (fixing things when they break) to proactive maintenance (preventing failures before they happen).

If your team is constantly troubleshooting slippage, dealing with premature roller wear, or struggling with inconsistent dimensions, it is time to move beyond the conventional solutions. The economic benefits of reduced downtime, lower roller consumption, and improved product quality make the investment in premium polyurethane technology a necessity, not a luxury.

Take the first step towards transforming your extrusion process. Contact Siva Rollers, your trusted PU Roller Manufacturer, today to discuss how our world-class Heavy Duty Rollers can deliver precision and longevity to your operations.

Get Your Custom PU Roller Solution Today

Whether you need a PU Roller, Polyurethane Roller, or Abrasion-Resistant Extrusion Roller, Siva Rollers can design, manufacture, and deliver the perfect solution for your plant.

Contact Siva Rollers — India’s leading PU-Coated Roller Manufacturer & Supplier

📞 Get a Free Quotation and expert consultation for your extrusion line needs.

🌐 Visit: https://www.sivarollers.com/contact-us/

FAQs

PU-Coated Rollers outperform traditional rollers because polyurethane offers superior abrasion resistance, chemical stability, and high-grip performance. Unlike rubber rollers that wear quickly or metal rollers that cause slippage, PU Rollers maintain precise pulling force, reduce downtime, and deliver consistent product quality even in harsh industrial conditions.

A PU Roller provides uniform traction and eliminates slippage during the haul-off process. This consistent pulling action ensures accurate thickness and dimensional stability in extruded profiles, films, and sheets. The result is fewer defects, smoother surfaces, and reduced material wastage.

Yes. PU-Coated Rollers have excellent resistance to oils, water, plasticizers, and solvents commonly present in extrusion environments. This makes them ideal for applications where rubber rollers degrade quickly due to chemical exposure, extending service life and maintaining operational reliability.

A High-Grip PU Roller ensures stable, slip-free pulling of the extruded product. Its optimized surface friction provides controlled movement, especially for smooth or polished plastic profiles. This stability is essential to maintain uniform haul-off speed and prevent product distortion or stretching.

A Urethane Haul-Off Pad is a polyurethane block or pad used in caterpillar-style haul-off systems. It provides maximum surface contact with the extruded profile, ensuring even pulling without surface damage. These pads are perfect for delicate or high-gloss plastic products where roller pressure must be distributed evenly.

Absolutely. PU Rollers can be engineered with custom durometer hardness levels to match specific material requirements. Softer durometers are suitable for flexible films and delicate sheets, while harder PU coatings are ideal for heavy-duty applications like pipe extrusion. This customization enhances both grip and longevity.

On average, PU-Coated Rollers last 5–10 times longer than traditional rubber rollers. Their exceptional tear and abrasion resistance make them ideal for continuous extrusion operations, reducing the frequency of roller changes and lowering total maintenance costs.

Yes. Many manufacturers, including Siva Rollers, offer roller recoating or refurbishment services. Instead of replacing the entire roller, the existing metal core can be cleaned, repaired, and recoated with high-performance polyurethane. This process significantly reduces replacement costs and supports sustainable operations.

Yes. Many manufacturers, including Siva Rollers, offer roller recoating or refurbishment services. Instead of replacing the entire roller, the existing metal core can be cleaned, repaired, and recoated with high-performance polyurethane. This process significantly reduces replacement costs and supports sustainable operations.

Choosing the right roller depends on factors such as extrusion speed, polymer type, surface finish requirements, and operating temperature. Working with a specialized PU Roller Manufacturer like Siva Rollers ensures you receive expert guidance, material testing, and a perfectly engineered roller designed for your exact process.

Switching to PU-Coated Rollers reduces maintenance downtime, extends equipment lifespan, lowers scrap rates, and minimizes roller replacements. Over time, these benefits translate to higher productivity, improved product consistency, and a stronger overall ROI for your manufacturing line.

Siva Rollers is India’s trusted manufacturer and supplier of PU-Coated Rollers, Urethane Haul-Off Pads, and Custom Durometer PU Rollers. With advanced coating technology and a focus on precision engineering, Siva Rollers delivers long-lasting, high-performance solutions tailored to your extrusion requirements.