Top PU Coated Rollers Suppliers in Pune – Request Quotation

In the high-stakes world of industrial manufacturing, the smallest component often dictates the overall efficiency of the production line. For plant heads and procurement managers in Pune bustling industrial sector, the quality of Industrial Rollers is not just a maintenance detail—it is a critical factor in uptime, product quality, and operational cost.

If you are dealing with frequent roller failures, inconsistent coating hardness, or poor chemical resistance, you are likely facing the consequences of subpar materials.

As one of the leading PU Coated Rollers Suppliers in Pune, Siva Rollers understands the engineering precision required to keep your lines running. Whether you operate in the automotive hub of Chakan or the packaging units in Bhosari MIDC, upgrading to high-performance Polyurethane (PU) coated rollers is the smartest investment for your facility.

The Hidden Cost of Low-Quality Rollers: Why Precision Matters

Before discussing solutions, we must address the problems plaguing the manufacturing floor. Many industries in Pune, from textile processing to steel rolling, rely on rubber or inferior-grade polymer rollers. While initially cheaper, these rollers often lead to “hidden costs” that bleed into profit margins.

Common Failure Points in Industrial Rollers:

- Rapid Wear and Abrasion: Standard rubber rollers often cannot withstand the friction of high-speed printing or conveyor lines, leading to frequent replacement cycles.

- Chemical Swelling: In printing and lamination, exposure to aggressive solvents, inks, and oils can cause low-quality rollers to swell, losing their dimensional stability and ruining product output.

- De-bonding and Delamination: Under heavy loads (common in steel and aluminum plants), the coating may peel away from the metal core if the bonding agent or curing process is flawed.

- Inconsistent Hardness: If a Polyurethane Coated Roller does not maintain uniform Shore A hardness across the surface, it causes uneven pressure, leading to wrinkling in films or uneven coating thickness.

The Solution? Precision-engineered PU Rollers from Siva Rollers.

Why Polyurethane? The Technical Edge for Pune Industries

Polyurethane is an engineering marvel that bridges the gap between rubber and plastic. It offers the elasticity of rubber combined with the toughness and durability of metal. For a PU Rollers Supplier catering to heavy industries, understanding the chemistry is key.

1.Unmatched Abrasion Resistance

PU coated rollers offer 3 to 4 times the abrasion resistance of standard rubber. For conveyor systems and material handling in Pune’s automotive sector, this translates to significantly longer service life and reduced maintenance shutdowns.

2. High Load-Bearing Capacity

Unlike rubber, which compresses and deforms permanently under heavy weight, high-grade Polyurethane has excellent compressive strength. This is vital for Steel & Aluminium Plants where rollers must support tons of metal without losing shape.

3. Superior Chemical and Oil Resistance

For Printing & Packaging Units, exposure to solvents is a daily reality. Siva Rollers utilizes specialized PU formulations that resist swelling when in contact with fuels, oils, grease, and printing inks.

4. Precision Finishing and Custom Hardness

We manufacture rollers ranging from soft (20 Shore A) for delicate film applications to extremely hard (95+ Shore A) for heavy-duty crushing or driving applications. Our grinding process ensures perfect concentricity.

Technical Insight: At Siva Rollers, we ensure excellent metal-to-PU bonding strength, preventing catastrophic delamination even under high-torque conditions.

Industry Applications: Who Needs PU Coated Rollers in Pune?

Pune is the industrial heartbeat of Western India. Siva Rollers caters to a diverse range of sectors, providing tailored solutions for specific production environments.

1. Printing and Packaging Industry

In rotogravure and flexographic printing, the transfer of ink and the handling of substrate require absolute precision. A variance of even a few microns can cause registration errors.

- Application: Impression rollers, inking rollers, and lamination nip rollers.

- Benefit: Excellent resistance to esters and ketones used in inks.

2. Steel and Aluminium Plants

The metal processing industry requires rollers that are tough. Cuts, gouges, and extreme weight are standard operating conditions.

- Application: Bridle rollers, squeegee rollers, and tension rollers.

- Benefit: High cut resistance and load-bearing capacity preventing sheet damage.

3. Plastic Film and Extrusion

Manufacturers of BOPP, PET, and PVC films require rollers that provide traction without marking the delicate film surface.

- Application: Nip rollers and guide rollers.

- Benefit: Non-marking surface properties and anti-static formulations.

4. Textile Processing

Textile units in and around Maharashtra require rollers that can handle wet environments and squeezing pressure.

- Application: Squeeze rollers and padding mangles.

- Benefit: Hydrolysis resistance ensuring the PU doesn’t break down in water/steam.

Serving Pune Key Industrial Hubs

Logistics and proximity matter. When a line goes down, you cannot wait weeks for a shipment from outside the state. As a premier PU Roller Manufacturer with a strong local presence, Siva Rollers ensures rapid turnaround times for new fabrication and recoating services across Pune’s major industrial zones:

Chakan & Talegaon

For the automotive OEMs and ancillaries in Chakan, we provide high-durability conveyor and assembly line rollers that meet international quality standards.

Bhosari MIDC & Pimpri-Chinchwad (PCMC)

Serving the dense network of engineering, fabrication, and packaging units in the heart of PCMC. We offer pickup and delivery services for roller recoating to minimize your downtime.

Ranjangaon & Sanaswadi

Supporting the white goods and heavy electronics manufacturing sectors with precision anti-static PU rollers.

Hadapsar & Shirwal

Catering to the diverse manufacturing landscape from processing industries to light engineering.

Need a site visit? We can deploy a technical expert to your facility in these areas to assess your roller requirements.

The Siva Rollers Advantage: Why Choose Us?

Searching for “PU Coated Rollers Suppliers in Pune” yields many results, but Siva Rollers stands out through a commitment to quality and engineering.

Custom Formulation

We don’t use a “one size fits all” approach. We select the specific Polyurethane prepolymer (TDI, MDI, or NDI based) depending on your operating environment (heat, wet, or dry).

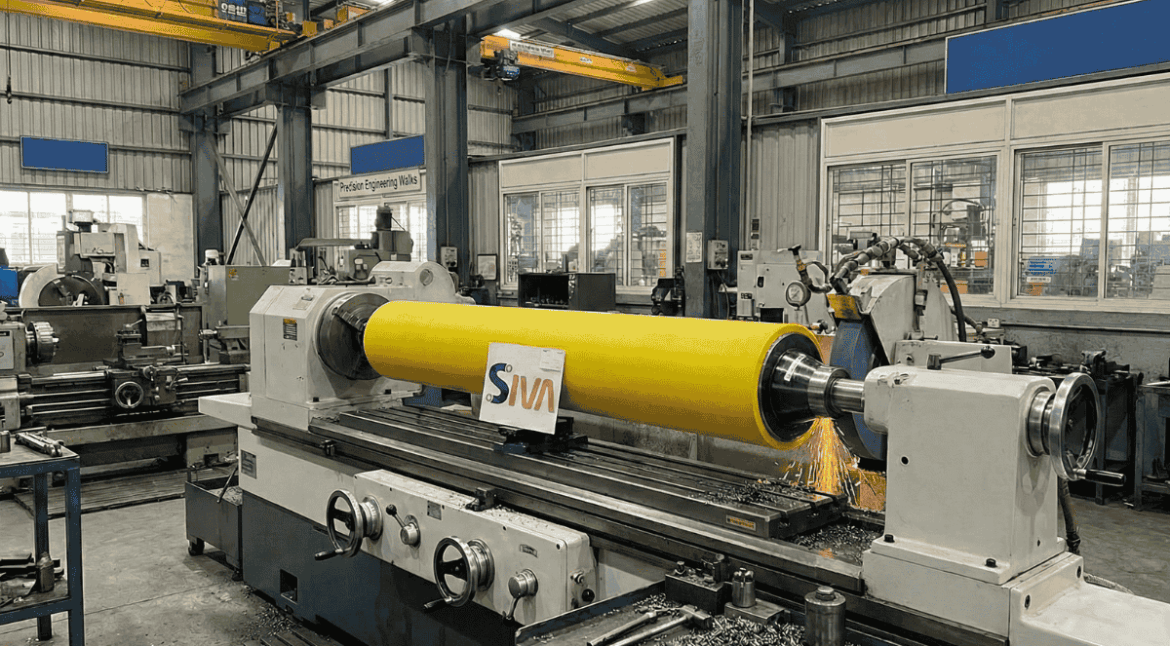

State-of-the-Art Manufacturing

Our facility is equipped with advanced casting machines and precision cylindrical grinders. We ensure:

- Perfect surface finish (Mirror, Matte, or Grooved).

- Tight tolerance on diameter and length.

- Dynamic balancing for high-speed applications.

The Recoating Experts

Don’t scrap your old metal cores. Siva Rollers specializes in Roller Recoating and Refurbishing. We strip the old covering, inspect the journal/shaft for damage, repair the core, and apply a fresh, high-performance PU coating. This saves you significant capital compared to buying new rollers.

Competitive Pricing & Bulk Order Capability

Whether you need a single prototype or a bulk order of 500 rollers for an OEM machine build, we offer competitive pricing structures tailored to procurement managers.

What We Need for a Quotation

To provide you with an accurate and fast quotation, please have the following details ready when you contact us:

- Core Material & Dimensions: (Total Length, Face Length, Diameter).

- Application: (e.g., Solvent printing, heavy load conveying).

- Required Hardness: (Shore A scale, e.g., 60A, 90A).

- Working Environment: (Temperature, presence of chemicals/oil).

- Quantity: (One-off or recurring monthly requirement).

Don’t have the technical specs? No problem. Send us a photo or a sample, and our engineers will reverse-engineer the requirement.

Stop Downtime, Start Producing

In the competitive industrial landscape of Pune, efficiency is the only currency that matters. Low-quality rollers are a leak in your production ship. By partnering with Siva Rollers, you are choosing reliability, precision, and longevity.

We are not just vendors; we are partners in your production success. From the bustling lanes of Bhosari to the sprawling plants of Chakan, Siva Rollers is the trusted name for PU Coated Rollers in Pune.

Ready to optimize your production?

Contact Siva Rollers Today

- Phone: +91 75070 10009

- Email: info@sivarollers.com

- Location: Pune, Maharashtra

FAQs

PU Coated Rollers are used for material handling, conveying, printing, laminating, tension control, and metal processing.

They deliver excellent load-bearing strength, abrasion resistance, and chemical resistance, making them suitable for printing & packaging, plastic film, steel & aluminium processing, and textile industries.

PU rollers last 3–4 times longer than rubber rollers because they offer superior abrasion resistance, hardness stability, and solvent resistance.

They maintain dimensional accuracy at high speed and under heavy load, reducing downtime and maintenance cost.

PU rollers are manufactured in the range of 20 Shore A to 98 Shore A hardness, depending on application requirements.

Soft hardness is ideal for delicate films, while high hardness supports steel handling, crushing, and high-pressure applications.

The cost depends on roller size, hardness grade, coating thickness, bonding type, and required finishing.

Recoating is generally 40–60% more economical than manufacturing a new roller.

Industries include printing & packaging, steel & aluminium, plastic film extrusion, textile processing, and automotive assembly lines.

These sectors depend on high-speed precision rollers for consistent product output and reduced downtime.

Yes. PU offers excellent chemical and oil resistance, making it ideal for printing inks, varnishes, adhesives, lubricants, and industrial fluids.

Yes, rollers can be produced in mirror, matte, grooved, and anti-static finishes with precision grinding for concentric accuracy.

Roller recoating replaces worn-out PU covering on an existing metal core instead of purchasing a new roller.

Recoating is recommended when the metal shaft and core are intact, reducing cost and delivery time.

Required details include: roller dimensions, hardness requirement, application, working temperature/chemicals present, and quantity.

If specs are unavailable, inspection or sample evaluation is possible.

Yes. Reputed suppliers like Siva Rollers provide onsite audit, pickup & drop for recoating, and fast delivery across Chakan, Bhosari, PCMC, Ranjangaon, and Talegaon.

Delivery time is usually 5–10 working days depending on size and production volume.

Emergency production and priority dispatch can be arranged.

Select the correct hardness, chemical-resistant PU grade, and precision-balanced finish for load and speed conditions.

Routine cleaning and avoiding excessive pressure improve longevity.